Omega II

®

Installation, Operation & Maintenance

Combustion Research Corporation

Page 33

5. The sensing probe detects the presence of the low fire

flame and the control de-energizes the spark and the

valve will remain open. Check valve outlet and other

downstream pipe connections with a soap solution.

6. Turn the thermostat to a low dial setting to open

contacts. The main gas flame should be extinguished.

7. For 100% shutoff check, set thermostat to low dial

setting (system off). Disconnect sensing probe lead at

control terminal.

8. Turn thermostat to a high dial setting to energize spark

ignition and valve. The gas should ignite. After 30

seconds, the system should "lockout" and burner

functions are off (no gas flow, no spark). If the system

does not go into "lockout," follow the installation

instructions to replace the control. Repeat the 100%

shutoff check. Note blower will not shut down when

ignition "lockout" occurs.

9. Set thermostat again to a low dial setting (system off),

connect probe lead to control terminal. Set thermostat

to normal setting to put system back in service.

CHECK SAFETY SHUTDOWN PERFORMANCE

WARNING

FIRE OR EXPLOSION HAZARD

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE DEATH, SEVERE INJURY

AND/OR PROPERTY DAMAGE.

Perform the safety shutdown test anytime work is done

on a gas system

.

NOTE: Read steps 1-7 below before starting safety

shutdown or safety lockout tests for the ignition module.

1. Turn gas supply off.

2. Set the thermostat or controller above room temperature

to call for heat.

3. Watch for ignition spark immediately or following pre-

purge. See ignition module specifications.

4. Time length of ignition operation. See ignition module

specifications.

5. After the module locks out, open gas control and ensure

there is no gas flow to main burner.

6. Set the thermostat below room temperature and wait

one minute.

7. Operate system through one complete cycle to ensure

all controls operate properly.

IGNITION CHECKOUT PROCEDURES

A combination voltmeter and micro-ammeter with a DC

micro-ammeter range setting of 0 to 10 micro-ampere is

required. Follow meter instructions for proper use. TO

CHECK AC VOLTAGES:

1. Set range selection switch to 150V AC before

connecting leads.

2. Connect wire leads in parallel with voltage to be

measured.

3. Read voltage on AC scale.

TO CHECK CURRENT FROM FLAME SENSING

PROBE:

1. Set range selector switch to 10 micro-amperes before

connecting leads.

2. Turn off power supply to ignition control.

3. Disconnect sensing probe cable from sensor terminal or

ignition control.

4. Connect red (positive) meter lead to sensor terminal.

5. Connect black (negative) meter lead to probe cable.

6. Turn on electrical supply to system and cycle system

through the thermostat.

7. After system has ignited, the meter should read 0.7

micro-amperes or higher. If less than 0.7 micro-

amperes, the control may need to be replaced. Check

all wiring connections before replacing control.

8. Turn off supply voltage.

9. Disconnect meter from sensor terminal and probe cable.

10. Reconnect probe cable to sensor terminal.

11. Turn on supply voltage.

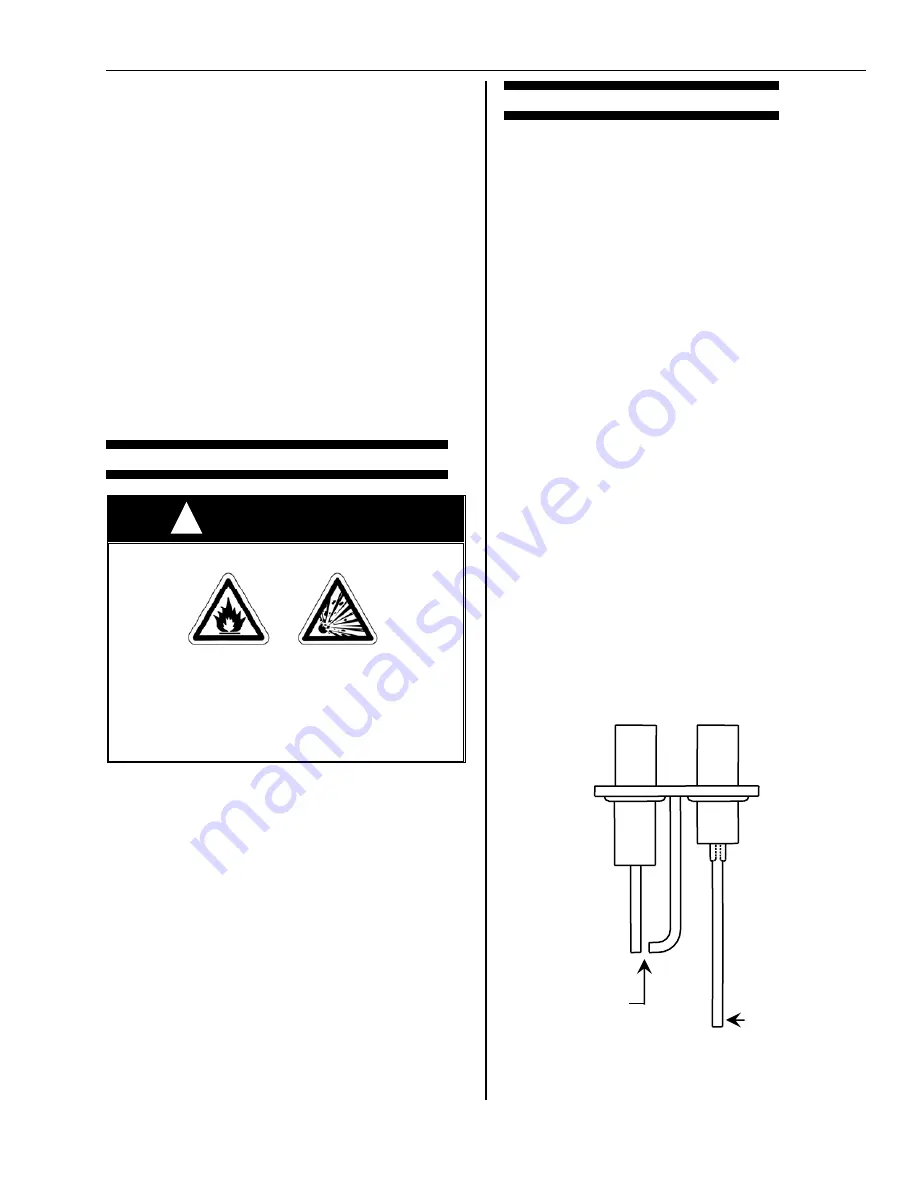

IGNITOR / FLAME SENSOR

0.10” Spark gap

Flame sensor

!

Summary of Contents for Omega II

Page 40: ...Omega II Installation Operation Maintenance Page 36 Combustion Research Corporation...

Page 48: ......

Page 49: ......