Reflect-O-Ray

®

Oil Fired EDS 3.5

Installation, Operation & Service

Page 8

Combustion Research Corporation

Radiant Tube Sub-Assembly:

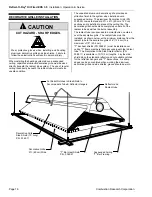

CAUTION

CUT HAZARD - SHARP EDGES.

Wear protective gloves when installing and handling

and cutting radiant tubes. Failure to follow these

instructions will result in personal injury.

If is recommend that a maximum of twenty-foot lengths of

radiant tube and possibly an elbow be assembled on the

floor before raising into position.

Experience has shown that it is best to start laying out the

system from the exhauster end, although this is not a

requirement. Avoid small segments that cannot be

supported properly according to the instructions in this

manual.

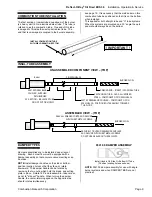

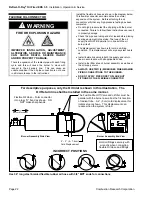

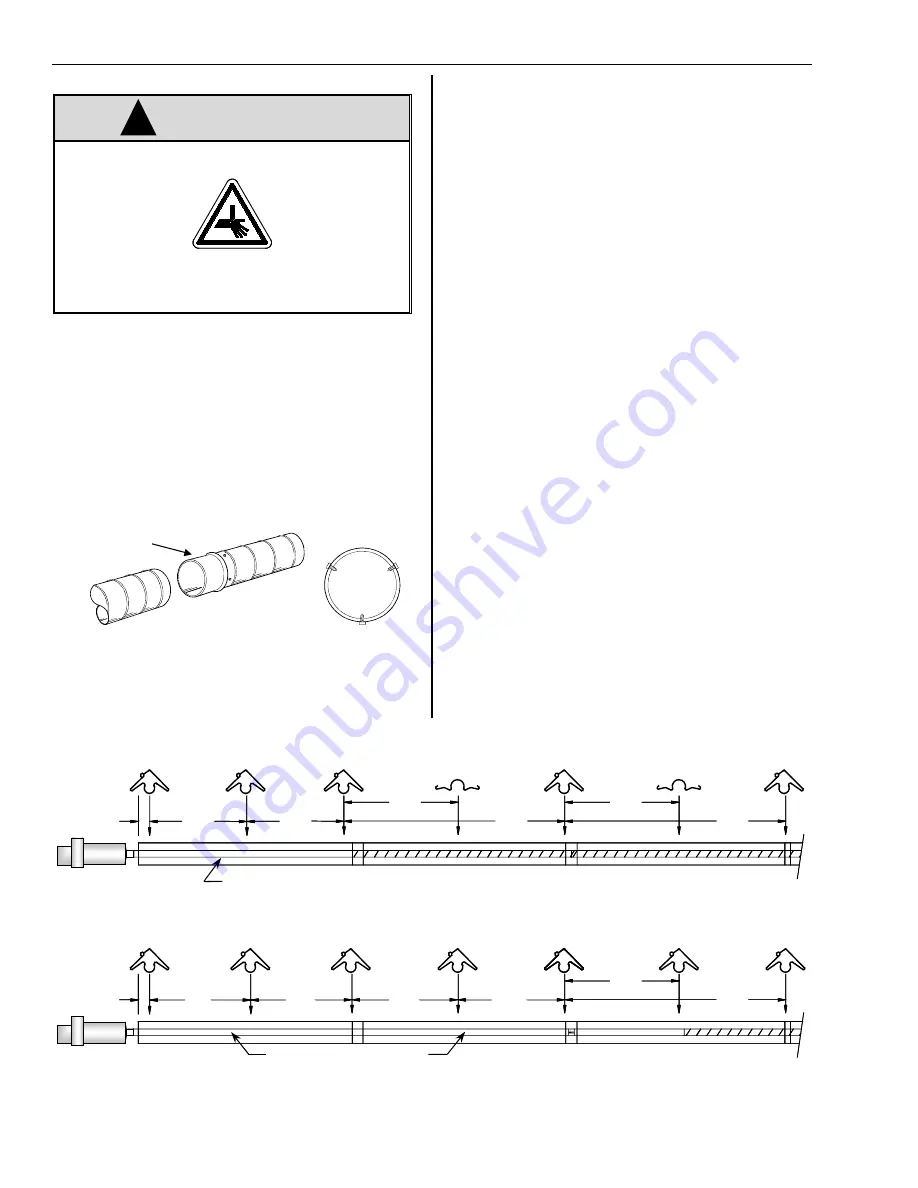

1. Apply sealer sparingly from the tube furnished to the

outside of the heat tube coupler, elbows, and other

fittings.

NOTE: Failure to use sealer can result in loss of vacuum.

Apply sealer sparingly to

outside of coupler

Placement of screws @

approximately 120°

2. Secure joint with sheet metal screws to provide a

mechanical joint rather than rely on friction. Use damp

cloth to remove excess sealer. Heat tube and fitting

assembly ends are designed for minimum clearance and

tight fitting to minimize air in filtration.

3. Insert coupler inside tube section. Be sure the radiant

tube is butted up tightly against the stop rim in the middle

of the coupler. Note: Tolerances are closely controlled at

this point to insure as tight a joint as possible. At this

point make sure that radiant tube sections to be joined

are straight and in line.

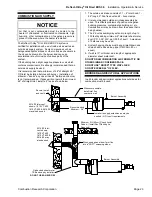

4. Attach combination hanger (0361.00) to the radiant tube

at dimensional support locations as outlined in this

manual. Combination hangers should be position so that

The locking loop / 45° suspension point, face the same

direction. Combination hanger’s (0361.00) shall be

positioned at all elbows and tee’s so as to provide

support for the adjoining reflector.

5. Position the intermediate reflector supports (0362.00)

between the combination hangers illustrated below.

6. Using two or more men, raise the length of pre

assembled tube sections up to suspension height, and

using "S" hooks or turnbuckles attach tube hangers to

suspension hardware.

7. Check to be sure all suspension hardware, chain, wire

rope, etc., is hanging straight. Reposition hangers where

necessary until suspension is straight.

8. Adjust suspension length until heat tube is straight and in

line. If possible, heat tube should be parallel with floor.

9. Proceed in manner described above to complete

hanging the remainder of the radiant tubes as described

and detailed in this owner's manual and the layout

drawing.

NOTE:

Review system layout carefully before any cutting

radiant tube. If cuts are not made where shown, radiant

tube lengths may be short and require additional tube

couplers to complete the project.

When cutting radiant tubes, de-burr them with a file to

remove sharp edges and facilitate easier assembly with

the couplers.

10. Make final check to be sure heat tube is straight and in

line before installing reflectors as illustrated on pages 13

- 15.

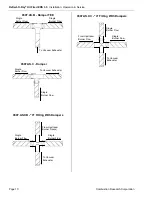

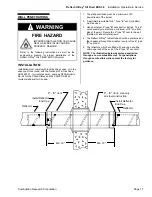

HANGER & SUPPORT LOCATIONS – STANDARD INSTALLATION

HANGER & SUPPORT LOCATIONS – “INSL” TUBE SYSTEM

5"

58"

58"

59"

118"

59"

118"

Hanger

Hanger

Hanger

Hanger

Support

Support

Hanger

5"

59"

59"

59"

118"

Hanger

Hanger

Hanger

Hanger

Hanger

Hanger

59"

59"

0304.INSL.25 – “INSL” Tube

0304.AS.16 – Aluminized Tube

Hanger

!