Reflect-O-Ray

®

Oil Fired EDS 3.5

Installation, Operation & Service

Combustion Research Corporation

Page 19

OIL SUPPLY

WARNING

FIRE OR EXPLOSION HAZARD

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE DEATH, SEVERE INJURY

AND/OR PROPERTY DAMAGE.

Proper and sound installation of oil lines must be

completed. Failure to do so may result in

premature failure and/or oil leaks.

Installation of oil burning equipment should be made in

accordance with NFPA Publication No. 31, obtainable

from the National Fire Protection Association. In Canada

the installation must conform to C.S.A. B139, Installation

Code for Oil Burning Equipment.

It must be understood that Combustion Research

Corporation cannot and does not represent that the

following information for oil circuits will satisfy any

particular local code requirements. Such compliance is the

sole responsibility of the installing contractor.

Particular note should be given to the installation of the

storage tank, piping, pump and valve installation to make

sure it complies with the above publications. Installation is

to be preformed by a qualified licensed contractor who is

familiar with liquid fuel burning systems. To insure a

proper and smooth operating installation, deviations from

the recommendations should be avoided. Deviations from

recommended installation can result in nuisance

shutdowns requiring emergency service. The following

precautions should be taken:

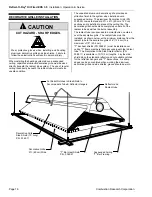

•

Do not place storage tank directly below roof

overhangs

•

Place tank in an area with the least direct sunlight

exposure - this will reduce internal sweating in an

unfilled portion of the oil tank.

•

Keep tank filled as much as possible - USE ONLY #2

OIL.

•

It is recommended that when bringing the #2 fuel oil

into the building a minimum 3/4" line should be used.

This line should be a minimum of 20' long and should

be run along the inside wall which will give the oil a

chance to warm up before it is pumped up to the

burner supply system.

•

Use a minimum 1/2" line to ceiling suspended storage

(day) tank.

•

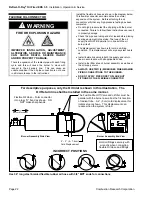

Install an oil filter in the suction side of the booster

pump as well as individual filters at each burner

assembly.

•

Proper fusible link valves and gate valves must be

installed.

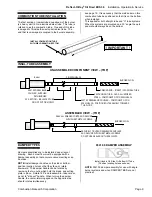

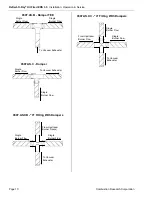

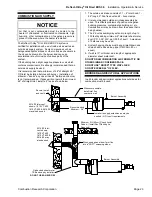

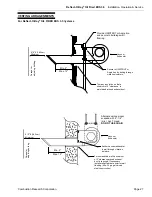

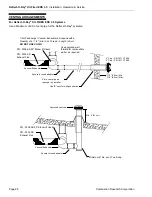

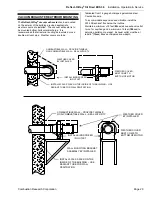

The following pages show two types of oil supply systems.

These schematics are for guidance purposes only.

Installation must comply with all national and local codes.

!