Reflect-O-Ray

®

Oil Fired EDS 3.5

Installation, Operation & Service

Page 26

Combustion Research Corporation

VENTING ARRANGEMENTS

WARNING

IMPROPER INSTALLATION CAN CAUSE

DEATH, SEVERE INJURY AND/OR

PROPERTY DAMAGE.

Improper venting and insufficient ventilation may result

in health problems, carbon monoxide poisoning and

death. Vent enclosed spaces and buildings according

to national, state, provincial and local codes.

♦

This radiant heater must be vented in accordance with

national, state, provincial and local codes and the

guidelines in this manual. In the United States refer to

the latest edition of the ANSI Z223.1 (NFPA 54)

Standard and in Canada refer to the latest edition of the

CAN/CGA B149.2 Standard.

♦

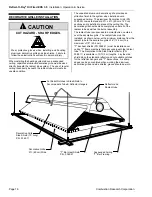

The layout drawing shows the general location of the

vacuum exhauster. Specific exhauster location and

discharge details must meet the following criteria:

♦

Make sure that the venting method selected is in

compliance with local codes.

♦

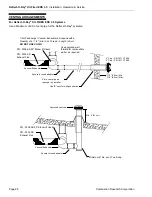

Heater may be vented to the outdoors vertically or

horizontally. The vent piping shall be adequately

supported to prevent sagging.

♦

Horizontal discharge is preferred through side walls.

The footage of horizontal vent pipe should be calculated

into the maximum system footage as outlined in the

charts on page 3. Vertical discharge must be arranged

as shown on page 28.

♦

Where the vent pipe passes through areas where the

ambient temperature is likely to induce condensation of

the flue gases the vent pipe shall be insulated.

♦

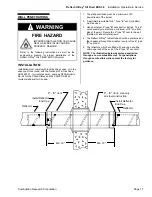

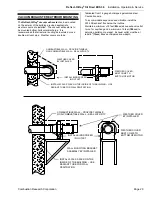

If the heater is to be vented horizontally:

a. Vent must terminate at least 3 feet (0.9m) above any

forced air inlet located within 10 feet (3.1m).

b. Vent shall terminate at least 4 feet (

1.2m

) below, 4

feet (

1.2m

) horizontally from, 1 foot (

30cm

) above any

door, window, or gravity air inlet into any building.

c. The bottom of the vent terminal shall be located at

least 12 inches (

30cm

) above grade and at least 6

inches (

15cm

) above anticipated snow depth.

d. Distances from adjacent public walkways, adjacent

buildings openable windows and building openings, are

to be consistent with ANSI Z223.1 (NFPA 54) Standard

and the CAN/CGA B149.2 Standard.

e. Vent must not terminate less than 6-ft

(1.8m

) from a

combustion air inlet of another appliance.

f. Vent must not terminate above a gas utility meter or

service regulator.

g. Vent terminal shall not be less than 7-ft

(2.1m)

above

grade.

♦

Vent opening must be beyond any combustible

overhang.

♦

Any portion of the flue pipe that passes through

combustible material of the building must have a

minimum 1" clearance.

♦

If condensation within the flue becomes a problem, the

flue should be shortened or insulated.

♦

Building materials should be protected from degradation

by flue gas products.

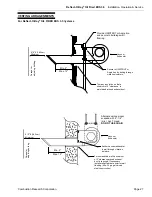

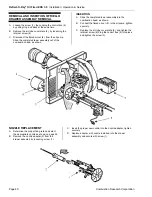

Recommended practice is to mount the vacuum exhauster

on the building inside wall. Alternatively the vacuum

exhauster may be suspended from the ceiling.

The vacuum exhauster can be mounted outside either on

roof or out side wall. The vacuum exhauster must be

protected from weather by mounting a hood over the

entire assembly. Vacuum exhausters are shipped

completely assembled. Scroll can only be rotated in 90°

increments.

The vacuum exhauster shall be installed so that the

discharge is bottom horizontal. Any other arrangement

will permit condensation to collect in scroll and cause

premature failure of scroll. For minimum corrosion of

scroll when mounted outside and the metal temperature of

the scroll is less than 150°F, it is recommended that the

casing be suitably insulated for protection against the

weather.

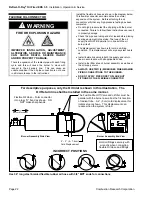

Motor and exhauster impellers are precision balanced and

bench tested as a complete assembly for vibration and

noise. It is important that care be used when handling the

vacuum exhauster to insure that it is not put out of balance

by dropping or careless handling.

Install the vibration isolating stainless steel flex (PN

0334.SS) as may be shown in the layout drawing. The

stainless steel exhaust flex is to be installed in a straight

line, rather than formed into an elbow.

The PN 0219.00 & 0419.00 exhaust vents are provided

with stainless steel bird screen as standard when

furnished by Combustion Research Corporation.

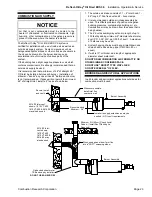

OPERATION

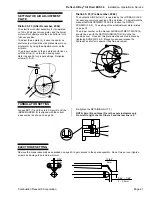

1. Before connecting the motor to the electric supply,

check the electrical characteristics as indicated on

the motor nameplate to insure proper voltage, phase,

and rotation.

2. After electrical connections are completed,

momentarily apply power, just enough to start the

vacuum exhauster unit. Be sure that the rotation of

the wheel is correct as indicated by directional arrows

on the unit. If proper rotation, apply full electrical

power.

3. With the complete system in full operation and all

ducts attached, measure current input to the motor

and compare with the nameplate rating to determine

if the motor is operating under safe load conditions.

!