Reflect-O-Ray

®

Oil Fired EDS 3.5

Installation, Operation & Service

Combustion Research Corporation

Page 33

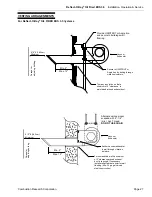

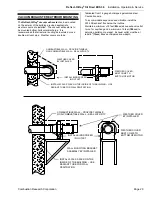

BURNER DIMENSIONS

13.5”

14.0”

14.5”

12”

22.5”

6.75”

41.25”

4: Dia. Combustion Air Inlet

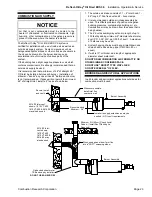

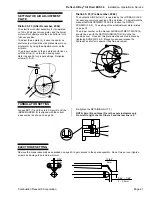

BURNER INTERNAL WIRING

Red

115 VAC, 60 Hz., 1.6 amp

POINT TO POINT DIAGRAM

115 VAC, 60 Hz., 1.6 amp

LADDER DIAGRAM

NO

C

P

N

Riello Burner

L2 (N)

L1 (H)

GND.

GREE

N

WHI

T

E

BL

AC

K

Red

NO

C

P

N

Riello Burner

L2 (N)

L1 (H)

GND.

GREE

N

WHI

T

E

BL

AC

K

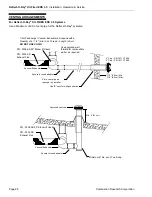

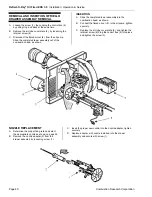

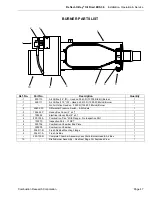

FUEL OIL CONNECTIONS

The

Reflect-O-Ray

®

Oil Fired EDS 3.5

system is shipped

as a two-pipe system. It is strongly recommended that the

system be installed as a two-pipe system. Most system

failures are due to the oil delivery system. A two-pipe

system greatly reduces the possibility of air entrapment

within the burner pump.

An external, appropriately listed and certified oil filter and

fusible link valves must also be installed at each burner

assembly. The oil filter is to be installed in the

INLET/SECTION line to the pump. Install a fusible link

valve up-stream of this filter.

Pipe dope or Teflon tape is NOT to be used on any direct

oil connection to the pump. Use the NPT/METRIC

adapters connected to the oil connection lines for

connecting the fuel supply and return lines.

Pipe dope or Teflon tape may be used on the NPT side of

the connector only.

NOTE: Use pipe dope and Teflon

tape carefully and sparingly so that none will get into

the oil pump assembly.

Refer to pages 22 & 42 for oil supply and oil connection

information.

Return

Inlet/Suction

Riello Oil Pump

NPT/Metric Adapter