Reflect-O-Ray

®

Oil Fired EDS 3.5

Installation, Operation & Service

Combustion Research Corporation

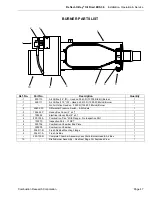

Page 37

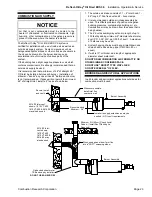

WARNING

ELECTRICAL SHOCK HAZARD

DANGER OF DEATH OR SEVERE

INJURY.

WARNING: ALWAYS DISCONNECT POWER

SUPPLY BEFORE SERVICING THE BLOWER

OR WORKING WITH THE UNIT FOR ANY

REASON. THIS IS ESPECIALLY IMPORTANT

WITH UNITS EQUIPPED WITH AUTOMATIC

THERMAL RESET PROTECTION. UNIT MAY

ACTIVATE WITHOUT WARNING!

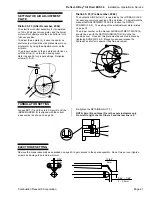

GENERAL AND YEARLY MAINTENANCE:

At regular intervals or at least once a year the entire

system should be inspected.

Reflect-O-Ray

®

Oil Fired EDS 3.5 BURNER

ASSEMBLY

:

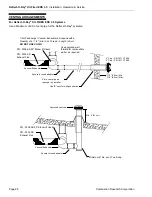

The oil supply system should be inspected for any leaks.

Oil filters and burner oil nozzles must be changed at least

once ever season.

Check combustion air inlets and connecting duct work for

obstructions and breakage; repair as needed.

Inspect hanging hardware, such as chains, for wear. If any

wear is present, the system must not be operated until the

chain(s) or associated hardware has been replaced.

Look for any deterioration in the housing assembly.

Replace or repair.

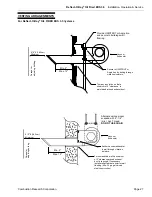

Radiant Tubing

:

WARNING

FIRE OR EXPLOSION HAZARD

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE DEATH, SEVERE INJURY

AND/OR PROPERTY DAMAGE.

Damaged or nonconforming radiant tubing must be

replaced with appropriate product as manufactured by

Combustion Research Corporation.

The

Radiant Tubing

should be inspected at the beginning

of every heating season. Look for cracks, holes, physical

damage, etc. Replace as needed.

NOTE:

Use only approved

Reflect-O-Ray

®

OIL FIRED EDS 3.5

radiant tube which has been specifically designed and

manufactured for the

Reflect-O-Ray

®

OIL FIRED EDS 3.5

system. Use of substitute materials can result in an

unsafe condition and will void any and all warranties.

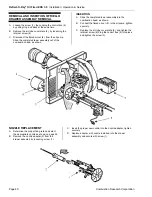

DIAGNOSIS AND TESTING

Reflect-O-Ray

®

OIL FIRED EDS 3.5 BURNER ASSEMBLY

:

If the burner does not operate, a "System Check"

must be made as follows:

WARNING

FIRE OR EXPLOSION HAZARD

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE DEATH, SEVERE INJURY

AND/OR PROPERTY DAMAGE.

Perform the safety shutdown test anytime work is done

on a oil system.

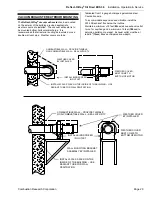

SYSTEM CHECK

1. Check for proper installation of unit (refer to owner's

manual).

2. If power is not present, check power supply to input

terminals with AC voltmeter and check fuse in burner

box.

3. Remove tube fitting from air switch and insert new

fitting with short rubber hose attached. Normally open

air flow switch can be operated with mouth vacuum to

check performance. If air flow switch does not close,

replace air flow switch.

4. Provided air flow switch is operating, listen for high

voltage arc, an audible spark "ticking."

(DO NOT

TOUCH IGNITION OUTPUT LEADS OR IGNITION

ELECTRODES.)

Check to see if high voltage leaks

occur at porcelains and high voltage leads.

5. If ignition arc is not present or sporadic, turn off power

and check gap. It should be approximately .10 inch.

(DO NOT TRY TO MEASURE HIGH VOLTAGE

OUTPUT.)

High voltage wire should not touch casing

as grounding can occur when wires are wet.

6. If ignition wires and electrodes are set as above, and

power is shown but no ignition arc is present, the

ignition assembly is defective and the electronics

should be replaced.

7. Inspect oil nozzle for correct size, replace at least

once ever season.

8. Disconnect power and check spade connections or

broken wires.

!

!

!