Reflect-O-Ray

®

Oil Fired EDS 3.5

Installation, Operation & Service

Combustion Research Corporation

Page 39

Regular preventive maintenance is important in

applications that place a heavy load on system controls,

such as in the commercial cooking and agricultural and

industrial industries because:

1. In applications where the equipment operates 100,000-

200,000 cycles per year. Such heavy cycling can wear

out the oil controls in one to two years.

2. Exposure to water, dirt, chemicals, and heat can

damage the oil control and shut down the control

system.

The Oil control Components should be

replaced if

:

1. It does not perform properly on checkout or trouble-

shooting.

2. The oil control is likely to have operated for more than

200,000 cycles.

CLEANING OF SYSTEM

Periodic cleaning of the reflectors can be done with a mild

soap and water solution. Wipe excess dirt and grim off the

top and underside of the reflectors which may have

collected.

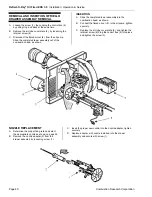

Burner assembly may also be cleaned in the same

manner.

Do not attempt to operate system for one (1) hour after

any cleaning process which may have included water.

In the unlikely event the radiant tube system requires

internal cleaning a 3.5" round brush assembly must be

used. Contact your representative or the factory for

guidance in obtaining this brush and the appropriate

method for cleaning.

MAINTENANCE PROGRAM

The maintenance program should include a regular check

out of the oil control. Maintenance frequency must be

determined individually for each application. Some

considerations are:

1.

Cycling frequency.

Appliances that may cycle

100,000 times annually should be checked monthly.

2.

Intermittent use.

Appliances that are used seasonally

should be checked before shutdown and again before

the next use.

3.

Consequence of unexpected shutdown

.

Where the

cost of an unexpected shutdown would be high, the

system should be checked more often.

4.

Dusty, wet or corrosive environment.

Since these

environments can cause the oil control to deteriorate

more rapidly, the system should be checked more

often.

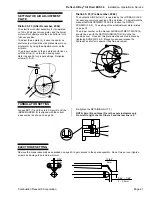

CHECKOUT PROCEDURE:

Before leaving installation, several complete operating

cycles should be observed to see that all components are

functioning properly.

1. Before turning on the main electrical power switch, be

sure all oil supply lines are purged of air.

2. Turn on main electrical power switch and close

thermostat contacts.

3. After the control is powered it will automatically

energize the spark and the oil valve.

4. The Cad Cell detects the presence of the flame and

the control de-energizes the spark and the valve will

remain open. Check valve outlet and other

downstream pipe connections for fuel oil leaks.

5. Turn the thermostat to a low dial setting to open

contacts. The main flame should be extinguished.

6. For 100% shutoff check, set thermostat to low dial

setting (system off). Disconnect sensing probe lead at

control terminal.

7. Turn thermostat to a high dial setting to energize spark

ignition and valve. The oil should ignite. After 30

seconds, the system should "lockout" and burner

functions are off (no oil flow, no spark). If the system

does not go into "lockout," follow the installation

instructions to replace the control. Repeat the 100%

shutoff check. Note blower will not shut down when

ignition "lockout" occurs.

8. Set thermostat again to a low dial setting (system off),

connect probe lead to control terminal. Set thermostat

to normal setting to put system back in service.

CHECK SAFETY SHUTDOWN PERFORMANCE:

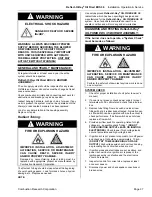

WARNING

FIRE OR EXPLOSION HAZARD

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE DEATH, SEVERE INJURY

AND/OR PROPERTY DAMAGE.

Perform the safety shutdown test anytime work is done

on a system

.

NOTE:

Read steps 1-7 below before starting safety

shutdown or safety lockout tests for the ignition

module.

1. Turn oil supply off at the burner assembly.

2. Set the thermostat or controller above room

temperature to call for heat.

3. Watch for ignition spark immediately or following pre-

purge. See DI module specifications.

4. Time length of ignition operation. See DI module

specifications.

5. After the module locks out, open fusible link valve on

the burner and ensure there is no oil flow to main

burner.

6. Set the thermostat below room temperature and wait

one minute.

7. Reset the burner and operate system through one

complete cycle to ensure all controls operate properly.

!