Reflect-O-Ray

®

EDS 6

Installation, Operation & Service

Combustion Research Corporation

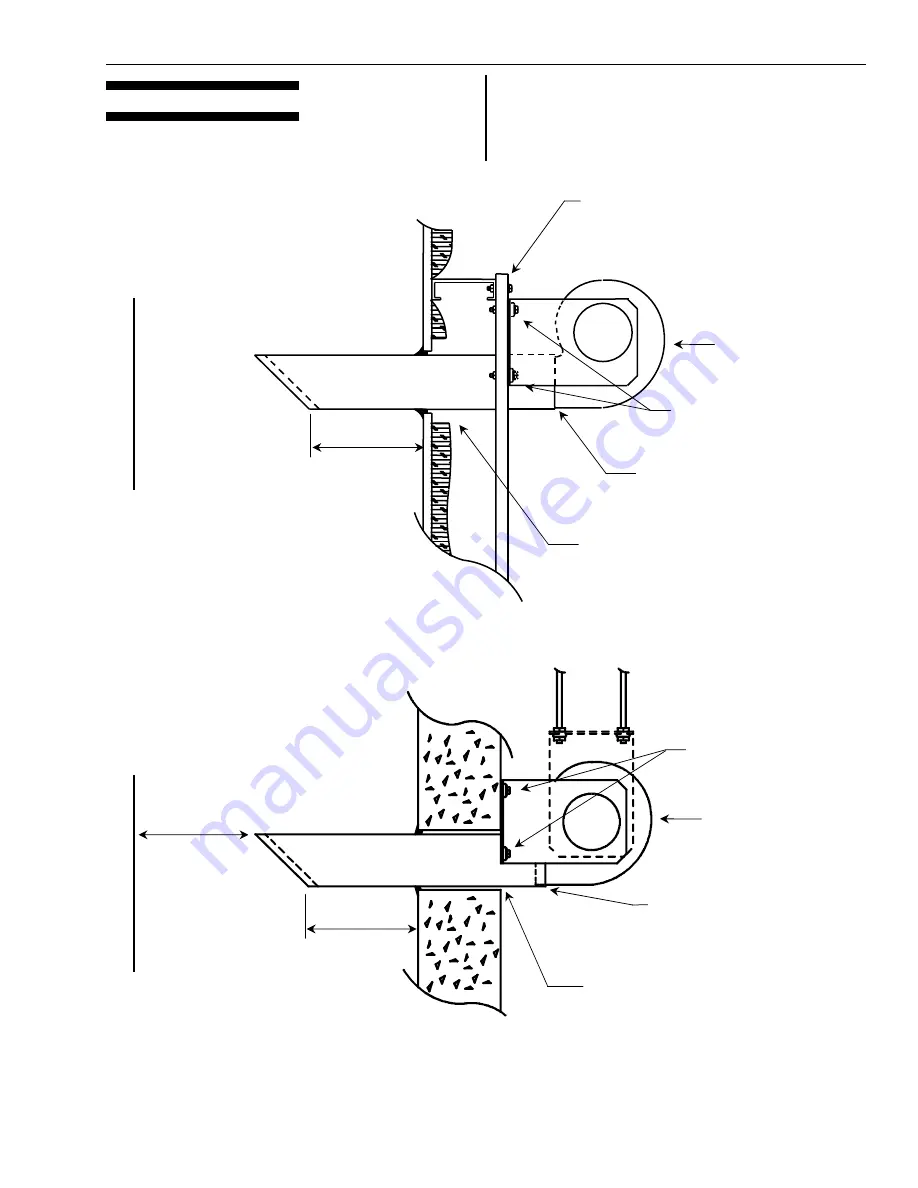

HORIZONTAL VENTING

Typically the Reflect-O-Ray

®

vacuum exhauster is mounted

on the side wall and vented horizontally with a rectangular

vent duct. The Reflect-O-Ray

®

system is certified to use

rectangular side wall vent duct as illustrated below.

Series 0401 and 0402 vacuum exhauster have rectangular

vent duct P/N 0419.000) available for side wall venting.

Horizontal Venting – Combustible Walls

Horizontal Venting – Non Combustible Walls

Page 21

Parapet o

r adjoining

building.

6.0’ (183 cm)

Use RTV silicone supplied with

rectangular vent duct to seal joint.

Secure duct to vacuum Exhauster

with minimum four, #10 SM screws

Min. 2"

Max. 12"

Provide UNISTRUT or Angle Iron and

secure to buildings wall framing

.

Vacuum

Exhauster

Secure to UNISTRUT or Angle

Iron by bolting through vibration

isolators.

Trim any insulation so that a minimum

of 6" (15 cm) clearance is maintained

around exhaust duct.

Use RTV silicone supplied with

rectangular vent duct to seal joint.

Secure duct to vacuum Exhauster with

minimum four, #10 SM screws

Min. 2"

Max. 12"

Alternate ceiling mount, suspend with

4 - 1/4" (min.) ALL Thread.

DO NOT USE CHAIN

Vacuum

Exhauster

Anchor vacuum exhauster to

wall through vibration isolators.

For combustible walls maintain a minimum of

4" (10 cm) clearance around exhaust duct. If

necessary the installer shall fabricate exterior

wall flashing (Min. 16 Ga. galvanized steel

construction)

Parapet o

r adjoining

building.

6.0’ (183 cm)