MicroBlaster MB1006

Section 1: The MicroBlaster MB1006

Comco Inc.

1-5

Issue Date: September 2003

How the MicroBlaster MB1006 Works

(cont’d)

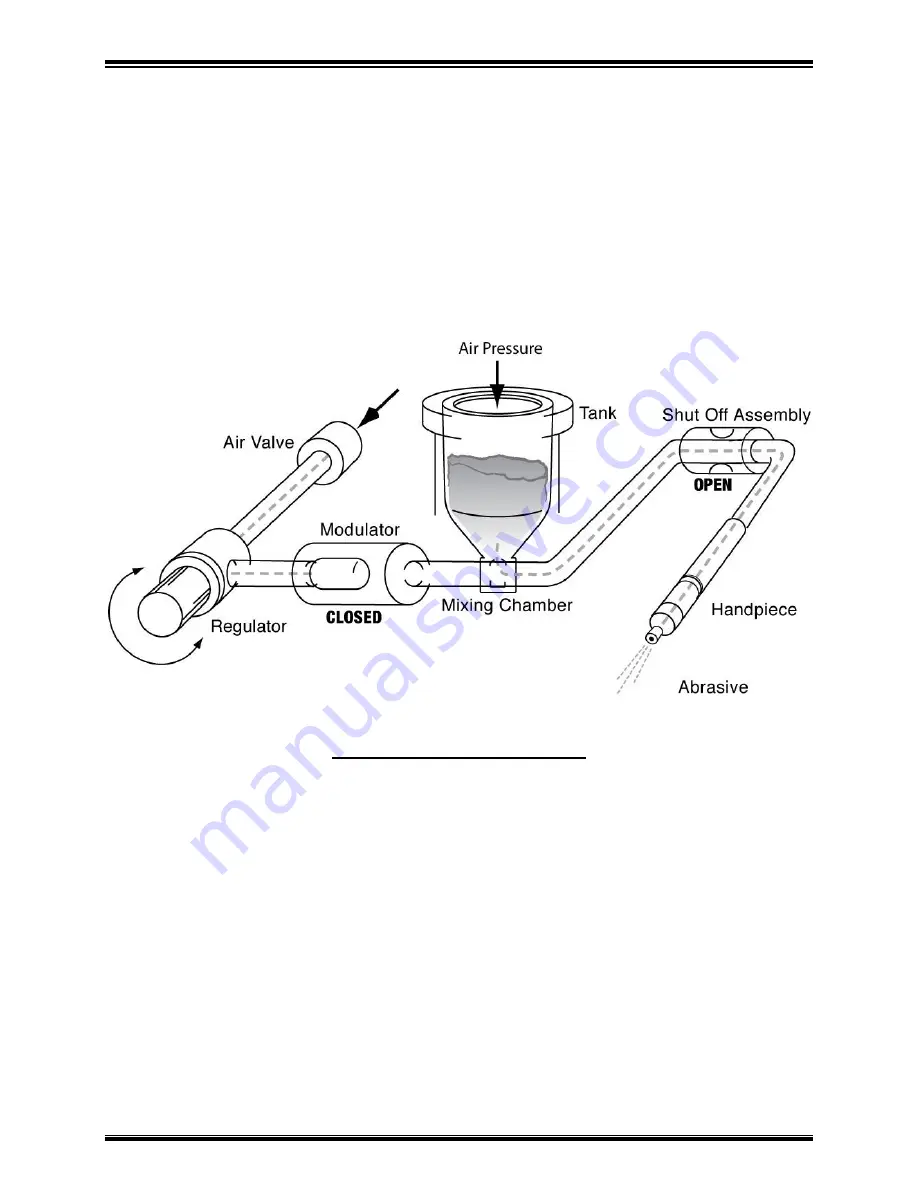

In the second half of the operating cycle, the modulator coil becomes energized. This

pulls the modulator core against the seat (see Figure 1-4, below), shutting off the airflow

from the regulator. The pressure in the mixing chamber now decreases because the

downstream end of the system, at the nozzle, is open to the atmosphere.

Since the pressure in the mixing chamber is lower than the pressure in the abrasive

tank, the two pressures try to balance. Air pressure inside the abrasive tank pushes a

small amount of abrasive through a precision orifice at the bottom of the tank, into the

mixing chamber and out through the nozzle.

Figure 1-4: Modulator Closed

When the next cycle begins, the modulator is again de-energized, and opens to allow

pressurized air to freely flow into the mixing chamber and out the nozzle. This forces air

back into the abrasive tank, stabilizing the pressure between the tank and the mixing

chamber (refer back to Figure 1-3).

Each cycle happens very quickly; 50-60 times per second. The end result of this

“stop/start” action of the modulator is a consistent stream of abrasive out the nozzle, as

long as the footswitch is depressed. Releasing the footswitch stops the modulator from

cycling and causes the pinch assembly to close the outlet air hose.

The only way for the abrasive powder in the tank to reach the mixing chamber is via the

orifice at the bottom of the tank. By changing the size of the tank orifice, you can

change the amount of abrasive that enters the mixing chamber, and thus change the

abrasion or cutting rate at the nozzle. Additional information regarding the tank orifice,

nozzle sizes, abrasives, and other variables in the abrasive blast process is presented in

Section 3 of this manual.

Summary of Contents for MicroBlaster MB1006

Page 10: ......