Section 2: Getting Started

MicroBlaster MB1006

Comco Inc.

2-2

Issue Date: September 2003

The Proper Work Area

The MicroBlaster should be used in an environment that:

Provides adequate ventilation.

Provides adequate lighting both inside and outside the primary

workstation. Comco recommends that the general environment be

illuminated with at least 50 decaluxes and that the interior of the

workstation be illuminated with a minimum of 125 decaluxes.

Is between 68ºF and 85ºF, with less than 40 percent relative humidity.

The MicroBlaster is intended for use in a factory or shop environment. It is

not

designed

for use where it could be exposed to rain, caustic chemicals, heavy vibration, and other

non-standard environments. Use in applications other than those described in this

manual may result in hazardous conditions and void the warranty.

Since it is impossible to achieve 100% containment of the abrasive within the system, it

is not recommended for use in a “clean room”.

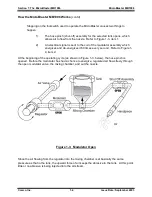

In addition to the MicroBlaster, typically three additional elements are needed for proper

micro-abrasive blasting: a workstation, a dust collector, and a dry air supply. The

following paragraphs explain the importance of each of these items. Refer to figure 2-1

to see how these items work together as a complete system.

Workstation

A suitable hood or box providing a means of working with the abrasive material without

contaminating the atmosphere of the room is required. It must protect the operator's

face and provide adequate light. The Comco WS2200 and WS6000 WorkStations are

designed for this purpose. Refer to Appendix C for more information.

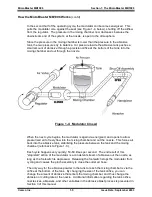

Dust Collector

In order to remove the spent abrasive, a suitable industrial dust collector is required.

These dust collectors have both high airflow and large filter areas to keep work areas

clean and dust free. The Comco DC2000 and DC2100 are both suitable dust collectors

for most micro-abrasive blasting applications. A four-inch diameter hose, supplied with

the dust collector, is used to connect the workstation to the dust collector.

Air Supply

The propellant required for the abrasive is compressed air or neutral gas that meets the

Detail Specifications outlined in Section 1. Comco has a complete line of air dryers for

shop (compressed) air supplies that will meet or exceed those specifications.

Bottled gas such as CO

2

or nitrogen provides clean, dry air, and may be used if shop air

is not available. However, depending on operating conditions, a 50 lb. bottle of gas will

only last 10-20 hours. Bottled gas does not require air dryers, but may require special

regulators. Contact Comco for more information.

Summary of Contents for MicroBlaster MB1006

Page 10: ......