Section 5: Trouble-Shooting and Repair

MicroBlaster MB1006

Comco Inc.

5-4

Issue Date: September 2003

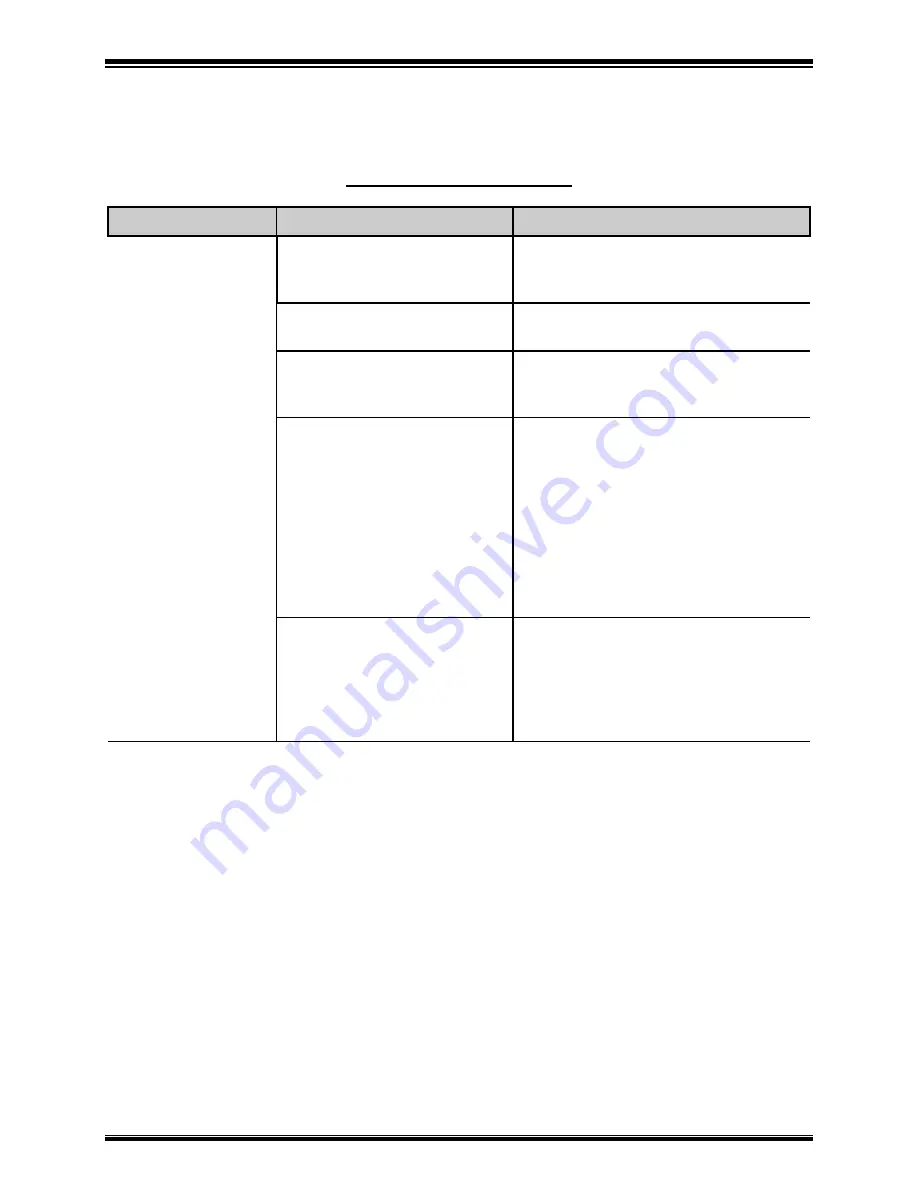

Common Problems, Causes, and Solutions

Table 5-1: No Air Flow

Problem

Items to Check

Solution

Nothing happens

when the

footswitch is

depressed

(No air is coming

out of the nozzle)

√

Is the electrical power

ON?

Verify that the POWER switch is ON

and the POWER LIGHT is

illuminated.

√

Is the fuse good?

Examine the fuse. Replace if

necessary.

√

Does the gage indicate

pressure in the

system?

Verify that shop air pressure of 80-

200 psig is supplied to the

MicroBlaster.

√

Is the nozzle plugged?

Remove the nozzle and depress the

footswitch. If a blast of abrasive

occurs, the nozzle was plugged. Tap

it on the workbench, back end down.

Discard the nozzle if it remains

plugged.

If plugging recurs, either the tank is

releasing too much powder or the

nozzle is too small for the powder.

√

Is the pinch valve

opening?

The abrasive hose should slide freely

through the abrasive pinch tube when

the footswitch is actuated. If it does

not, the valve is not functioning

properly. See maintenance of the

pinch valve below.

Summary of Contents for MicroBlaster MB1006

Page 10: ......