17

Using the SAVE command will overwrite the location with the current valve data.

The Quick Valve feature allows the user to save the selected valve to a memory location which is

quickly accessible without having to use the ‘Select Valve’ option. The purpose of this is to reduce

time when commissioning a system with, for example, 3 different types of valve. The 3 types of

valve could be saved to the Quick Valve memory including the design flow designated for that valve.

When recalled, the valve will be loaded to the unit including the design flow.

Follow the on-screen instructions to save the current selection or delete the existing saved valve.

An additional use for this feature is the ability for the user to save the commissioned data for up to

100 valves for later reference.

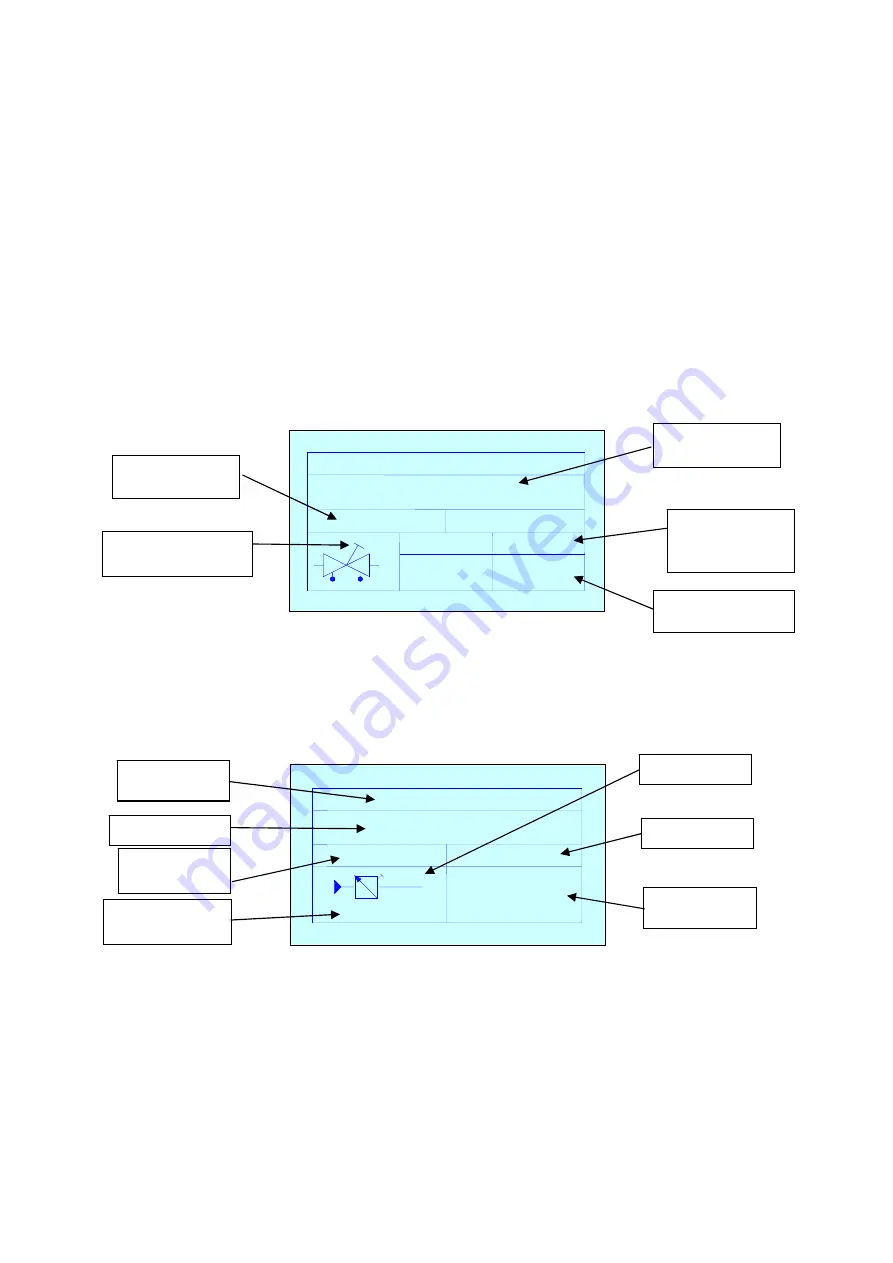

When the data for the selected valve has been saved, the following screen appears. The example

shown is for a variable orifice double-regulating valve (all other valve types have a simpler screen).

When using automatic balancing valves, the procedure for using ‘Quick Valve’ is the same as if

traditional balancing valves but the screen showing saved data is different as shown below.

The above example shows that the actual DP is greater than the design DP therefore the flow

status is displayed as FLOW OK.

Further options for saving valve data are available if PcomPRO Project Application Software is

purchased with the AC6 unit – see Chapter 7.

Group 1 Valve 1

19.23 kPa

0.487 l/s

Crane Variable D930DM930 15mm

DESIGN 244 %

TARGET 271 %

DESIGN FLOW

TARGET FLOW

0.2

90%

4

Valve saved to

this location.

DP and flow data

currently saved.

Design flow and

target flow %

currently saved.

Handwheel setting

currently saved.

Design and target

flow currently set.

Group 1 Valve 1

21.5 kPa

0.210 l/s

Flowcon green ‘0’

FLOW OK

5

16.00 kPa

Group and

valve No.

Selected valve.

Current flow

status.

Design flow.

Actual DP

across valve.

Valve setting.

DP required for

design flow.