©COMEV

AL

V

AL

VE SYSTEMS

Technical Dept. Ref. IOM - PNEUMA

TIC

ACTUA

TORS

AF SERIES - Ed.20/1

1

Comeval V

alve Systems reserves the right to alter any technical data contained in this Manual without prior notice. Regularly updated data on www

.comeval.es

COLUMNLESS PNEUMATIC ACTUATORS AF SERIES

FOR DIAPHRAGM VALVES

Page 7

Recommended Spare parts

(see parts list in Chapter 13

Use only original spare parts.

It is advisable to keep parts 15 and 8 as spare parts. Type and number of each spare part to be stored according to many

factors: service level, actuators’ quantity, etc. In many cases a good choice is to keep complete actuator as spare part.

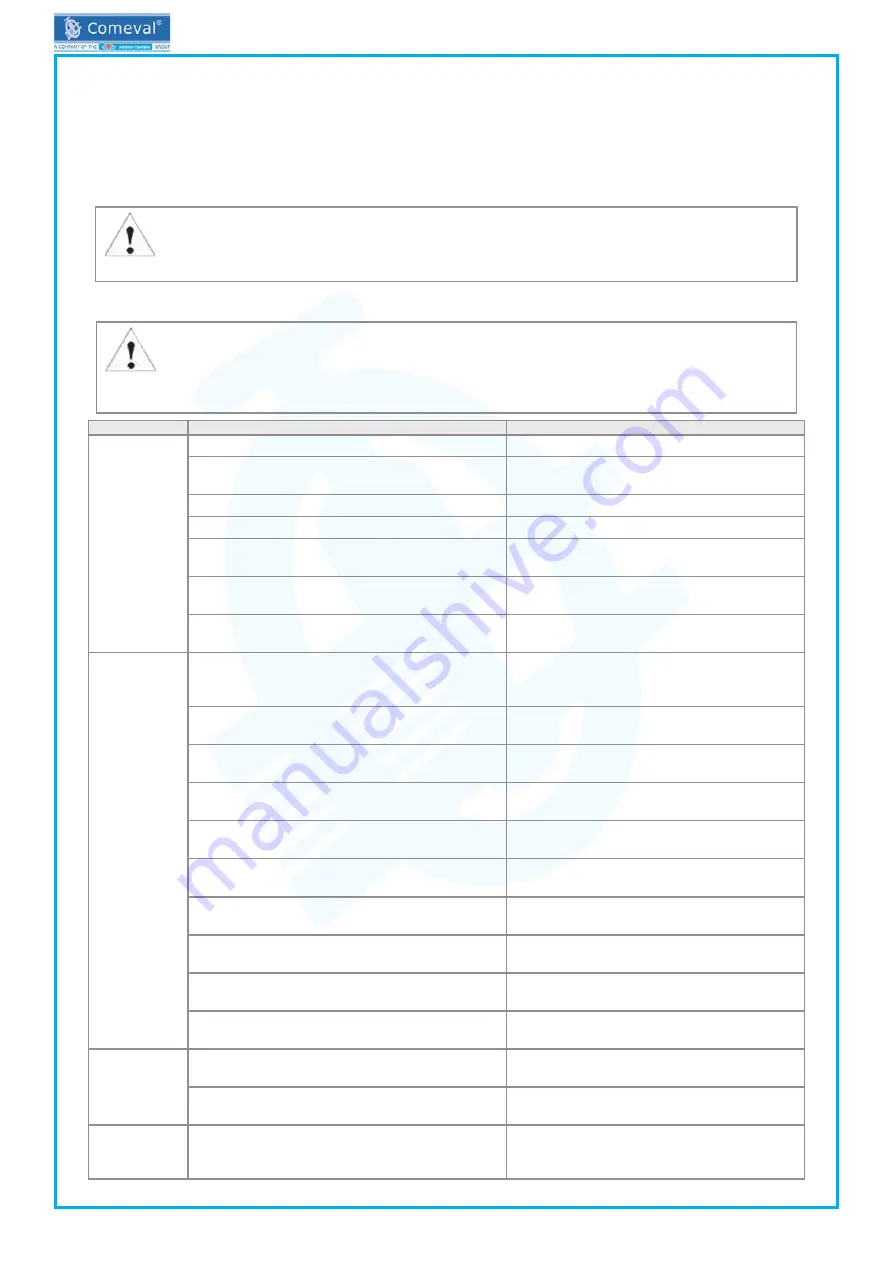

8. TROUBLESHOOTING

In the event of malfunction or faulty operating performance, check that the installation and adjustment work has been carried

out and completed in accordance with this Manual.

ATTENTION!

- It is essential that the safety regulations are observed when identifying faults.

9. TROUBLESHOOTING TABLE

ATTENTION!

- Read the complete Manual before carrying out installation and repair work.

- Read chapter 6 before recommissioning

.

FAULT

POSSIBLE CAUSE

CORRECTING MEASURES

Actuator unit

does not

move

Wrong air supply connection

Check correct air supply connection

Connection opposite to air supply connection

(venting) is plugged or blocked, not venting

Discard this

No air supply pressure or too low

Check air supply pressure

Actuator already reached limit position

Check actuator position

Actuator manual device (handwheel) limiting the

operation

Release the manual handwheel to allow

pneumatic operation

Spring broken

Check spring and replace if needed. Refer to

chapter 7

Some part stuck inside the valve

Dismount the valve and check inside. Refer to

chapter 7

Actuator unit

moves too

slowly or not

reaching limit

position

Air supply pressure too low

Recheck air supply pressure on actuator

nameplate. Increase only the needful, without

exceeding max.value

Connection opposite to air supply connection

partially plugged or restricted

Discard this

Significant leakage on air supply line

Correct leakage, retigthen fittings if needed.

Refer to chapter 6

Air supply line restricted, solenoid valve or

positionner obstructed or wrongly adjusted

Check inlet air supply system

Actuator manual device (handwheel) limiting the

operation

Release the manual handwheel to allow

pneumatic operation

Actuator diaphragm not properly assembled (upper

and lower chamber communicated)

Ensure the diaphragm is well clamped in its

raised center to make tightness

Actuator diaphragm damaged (upper and lower

chamber communicated)

Replace diaphragm. Refer to chapter 7

Leakage between upper and lower case

Retighten chambers union bolts or replace

actuator diaphragm. Refer to chapter 6 and 7

Too much pressure on the main line, medium to

viscous or with impurities

Check working parameters

Spring broken

Check spring and replace if needed. Refer to

chapter 7

External

air leakage

through

actuator

Leakage between upper and lower chamber

Retighten chambers union bolts or replace

actuator diaphragm. Refer to chapter 6 and 7

Leakage from upper or lower chamber

Retighten bolts or replace o-rings in bonnet

and/or in spring’s seat. Refer to chapter 6 and 7

Actuator unit

moves too

quickly

Air supply pressure too high

Recheck air supply pressure acc. to actuator

nameplate. Set to the minimum necessary to

operate the valve