©COMEV

AL

V

AL

VE SYSTEMS

Technical Dept. Ref. IOM - PNEUMA

TIC

ACTUA

TORS

AF SERIES - Ed.20/1

1

Comeval V

alve Systems reserves the right to alter any technical data contained in this Manual without prior notice. Regularly updated data on www

.comeval.es

COLUMNLESS PNEUMATIC ACTUATORS AF SERIES

FOR DIAPHRAGM VALVES

Page 3

4.2

Principle of Operation

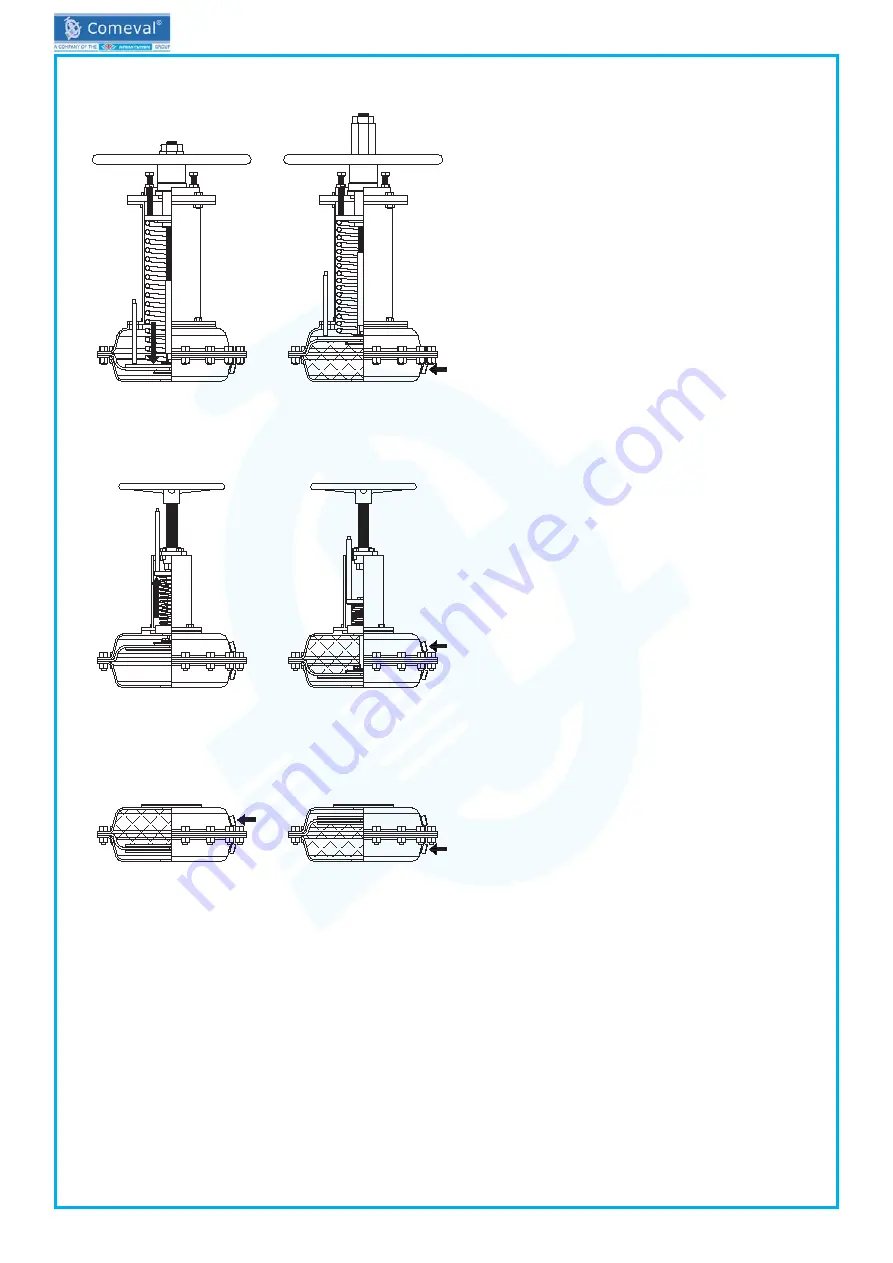

Single acting, spring return, normally closed actuator

air inlet

When the lower chamber is pressureless the spring forces the valve’s stem down to close. If the lower chamber has enough

air pressure to counter the spring’s force (based on limit rod screws set up) and the pipeline diferential pressure, the diaphragm

upper plate pushes up the spring and therefore the valve opens.

Single acting, spring return, normally closed actuator

air inlet

When the upper chamber is pressureless the spring forces the valve to remain open, the % on the opening could be easily

adjusted by using the handwheel which actuate directly to the stem extension. When the upper chamber have enough air

pressure to counter the pressure of the line and the spring’s force, the air push the diaphragm downwards and this pull the

stem extension with it forcing the valve to close.

Double acting

air inlet

air inlet

When the upper chamber’s air pressure is enough to allow the valve to close, the air pushes the diaphragm downwards and

so it actuates directly on the valve’s stem forcing the valve to close. When the air pressure in the lower chamber is enough to

allow the valve to open, the diaphragm push upwards the stem and so the valve open.

4.3

Area of Application

Diaval® AF actuators have been designed to automatize diaphragm valves installed on pipelines for liquids or gases suitable

for the valves.

4.4

Technical data – remarks

Check installation area’s special requirements, air supply and temperature limits and other essential parameters. Ensure

proper safety devices/measures are implemented to prevent exceeding intended use of the product. Refer to Data Sheet for

data such as main features, duties/limits of use, dimensions, weights, etc. and consult the manufacturer for further information.

Bear in mind that for the correct operation, a pneumatic actuator must be sized adequately and with sufficient safety margin

of thrust output for the correct operating conditions of the valve.

Spring return actuators are equiped with visual indicator rod.