508134-01

Issue 2045

Page 32 of 53

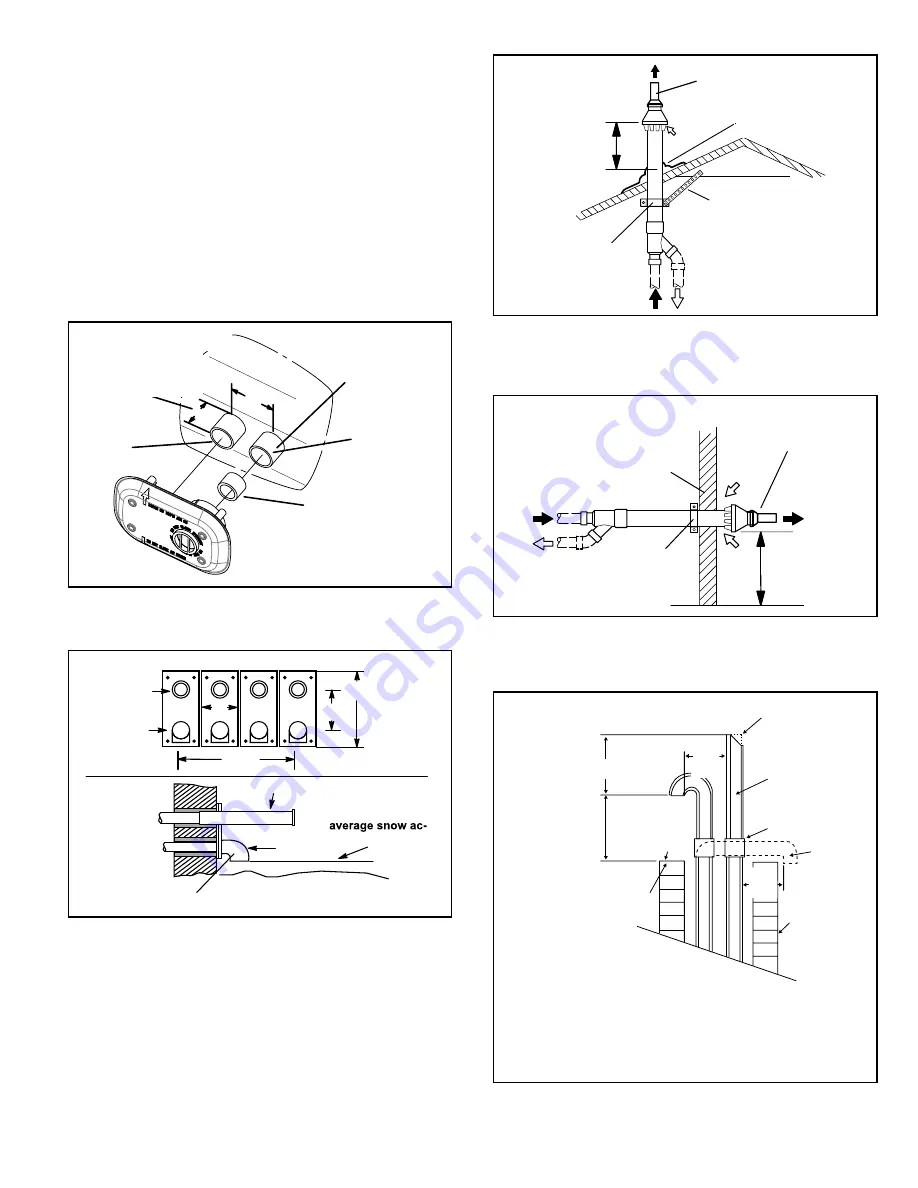

7. If intake and exhaust piping must be run up a side

wall to position above snow accumulation or other

obstructions, piping must be supported. At least one

bracket must be used within 6” from the top of the

elbow and then every 24” (610mm) as shown in Figure

40, to prevent any movement in any direction. When

exhaust and intake piping must be run up an outside

wall, the exhaust piping must be terminated with pipe

sized per Table 13.The intake piping may be equipped

with a 90° elbow turndown. Using turndown will add 5

feet (1.5m) to the equivalent length of the pipe.

8.

A multiple furnace installation may use a group of up to

four terminations assembled together horizontally, as

Figure 32.

Flush-Mount Side Wall Termination Kit

51W11 (US) or 51W12 (Canada)

1-1/2” ACCELERATOR

(all -45, -070 and -090 units)

FURNACE

EXHAUST

PIPE

FURNACE

INTAKE

PIPE

4''

GLUE EXHAUST

END FLUSH INTO

TERMINATION

2” EXTENSION FOR

2” PVC PIPE

1” EXTENSION FOR

3” PVC PIPE

EXHAUST

VENT

INTAKE

AIR

5-1/2”

(140mm)

Front View

12”

(305mm)

5”

(127mm)

18” MAX.

(457mm)

EXHAUST VENT

INTAKE

AIR

Inches (mm)

Side View

12” (305mm) Min.

above grade or

cumulation.

optional intake elbow

Figure 33. Optional Vent Termination for Multiple Unit

Installation of Direct Vent Wall Termination Kit

Figure 34. Direct Vent Concentric Wall Termination

71M80, 69M29 or 60L46 (US)

44W92 or 44W93 (Canada)

Minimum

Above Average

Snow

Accumulation

SHEET METAL STRAP

(Clamp and sheet metal strap

must be field installed to support

the weight of the termination kit.)

FLASHING

(Not Furnished)

CLAMP

FIELD-PROVIDED

REDUCER MAY BE REQUIRED

TO ADAPT LARGER VENT

PIPE SIZE TO TERMINATION

1 1/2” (38mm) accelerator

provided on 71M80 & 44W92

kits for -045 and -070 models

12” (305mm)

INTAKE

AIR

EXHAUST

VENT

Figure 35. Direct Vent Concentric Wall Termination

71M80, 69M29 or 60L46 (US)

44W92 or 44W93 (Canada)

12” (305mm) Min.

above grade or

average snow

accumulation.

INTAKE

AIR

INTAKE

AIR

INTAKE

AIR

OUTSIDE

WALL

GRADE

CLAMP

(Not Furnished)

FIELD-PROVIDED

REDUCER MAY BE REQUIRED

TO ADAPT LARGER VENT

PIPE SIZE TO TERMINATION

EXHAUST

VENT

1-1/2” (38mm) accelerator

provided on 71M80 & 44W92

kits for -045 and -070 models

EXHAUST

VENT

STRAIGHT-CUT OR

ANGLE-CUT IN DIRECTION

OF ROOF SLOPE *

EXHAUST VENT

1/2” (13mm)

WEATHERPROOF

INSULATION

SHOULDER OF FITTINGS

PROVIDE SUPPORT

OF PIPE ON TOP PLATE

ALTERNATE

INTAKE PIPE

INTAKE PIPE

INSULATION (optional)

EXTERIOR

PORTION OF

CHIMNEY

INSULATE

TO FORM

SEAL

SHEET

METAL TOP

PLATE

8” - 12”

(203mm - 305mm)

* SIZE TERMINATION

PIPE PER EXHAUST

PIPE TERMINATION

SIZE REDUCTION

TABLE

3” - 8”

(76mm -

203mm)

3” - 8”

(76mm -

203mm)

Minimum 12” (305mm)

above chimney top

plate or average snow

accumulation

NOTE

− Do not discharge exhaust gases directly into any chimney

or vent stack. If vertical discharge through an existing unused

chimney or stack is required, insert piping inside chimney until the

pipe open end is above top of chimney and terminate as illustrated.

In any exterior portion of chimney, the exhaust vent must be

insulated.

Figure 36. Direct Vent Application Using Existing

Chimney