508134-01

Issue 2045

Page 10 of 53

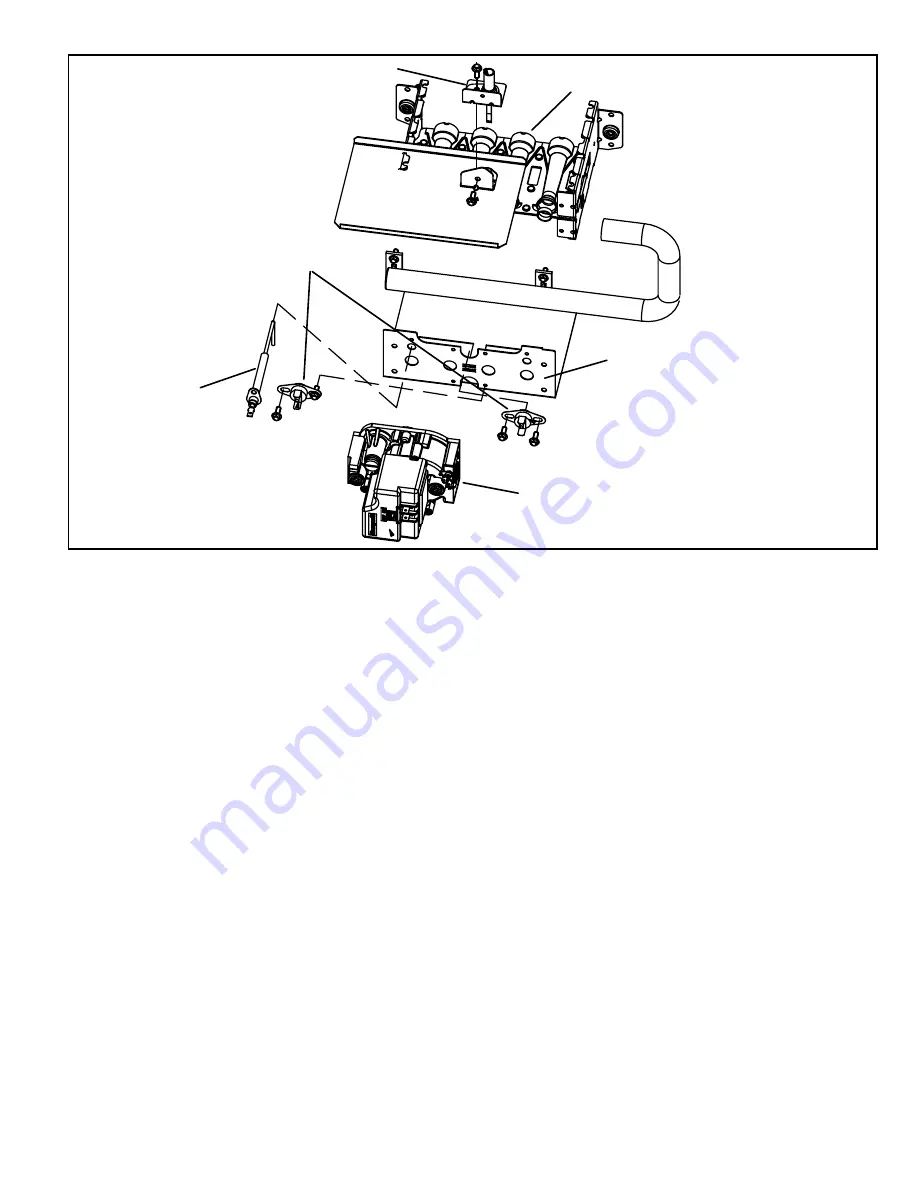

Figure 5. Burner Box Assembly

SENSOR

ROLLOUT SWITCHES

GAS VALVE

IGNITOR

BURNERS

FRONT BURNER BOX PLATE

Flame Rollout Switches (Figure 5)

Flame rollout switches S47 are SPST N.C. high temperature

limits located on the left and right of the front buner box

plate. S47 is wired to the burner ignition control A92. When

either of the switches sense flame rollout (indicating a

blockage in the combustion passages), the flame rollout

switch trips, and the ignition control immediately closes

the gas valve. Switch S47 in all

GDD92C

units is

factory preset to open at 210 F + 12 F (99 C + 6.7 C)

on a temperature rise. All flame rollout switches are

manual reset. See flash code 8 in Table 4 or Table 5 for

troubleshooting.

A flame sensor is located on the left side of the burner

support. The sensor is mounted on the front burner box

plate and the tip protrudes into the flame envelope of the

leftmost burner. The sensor can be removed for service

(use steel wool only to clean) without removing any part of

the burners. During operation, flame is sensed by current

passed through the flame and sensing electrode. The

ignition control allows the gas valve to remain open as long

as flame signal is sensed.

NOTE:

The

GDD92C

is polarity sensitive. Make sure

that the furnace is wired correctly and is properly grounded.

A microamp DC meter is needed to check the flame signal

on the integrated control.

Flame (microamp) signal is an electrical current which

passes from the integrated control to the sensor during

unit operation. Current passes from the sensor through the

flame to ground to complete a safety circuit.

GDD92C

units use an aluminized steel primary and

stainless steel secondary heat exchanger assembly.

Heat is transferred to the air stream from all surfaces of

the heat exchanger. The shape of the heat exchanger

ensures maximum efficiency.

The combustion air inducer pulls fresh air through the

burner box. This air is mixed with gas in the burners. The

gas / air mixture is then burned at the entrance of each

clamshell. Combustion gases are then pulled through the

primary and secondary heat exchangers and exhausted

out the exhaust vent pipe.