507715-01

Page 30 of 61

Issue 1716

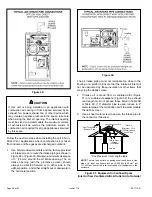

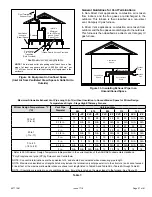

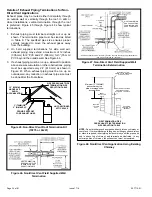

In both Non–Direct Vent and Direct Vent applications, the

vent termination is limited by local building codes. In the

absence of local codes, refer to the current National Fuel

Gas Code ANSI Z223-1/NFPA 54 in U.S.A., and current

CSA-B149 Natural Gas and Propane Installation Codes in

Canada for details.

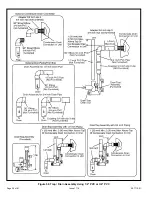

Position termination according to location given in Figure

34 or Figure 35. In addition, position termination so it is

free from any obstructions and 12” above the average

snow accumulation.

At vent termination, care must be taken to maintain

protective coatings over building materials (prolonged

exposure to exhaust condensate can destroy protective

coatings). It is recommended that the exhaust outlet not be

located within 6 feet (1.8 m) of a condensing unit because

the condensate can damage the painted coating.

NOTE:

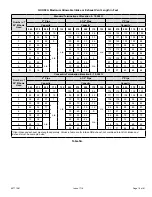

See Table 7 for maximum allowed exhaust pipe

length without insulation in unconditioned space during

winter design temperature is below 32° F (0° C). If required,

exhaust piping should be insulated with 1/2” (13 mm),

Armaflex or equivalent. In extremely cold climate areas with

temperature below 20° F (6.7° C) it is recommended that,

3/4” (19 mm) Armaflex or equivalent be used. Insulation on

outside runs of exhaust pipe may be painted or wrapped

to protect insulation from deterioration in accordance with

the insulation manufacturers recommendation. Exhaust

pipe insulation may not be necessary in some specific

applications.

NOTE:

During extremely cold temperatures, below

approximately 20° F (6.7° C), units with long runs of vent

pipe through unconditioned space, even when insulated,

may form ice in the exhaust termination that prevents the

unit from operating properly. Longer run times of at least 5

minutes will alleviate most icing problems. Also, a heating

cable may be installed on exhaust piping and termination

to prevent freeze-ups. Heating cable installation kits are

available. See unit specification sheets for part numbers.

Do not use screens or perforated metal in exhaust

terminations. Doing so will cause freeze-ups and may

block the terminations.

IMPORTANT

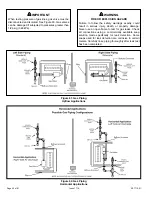

For Canadian Installations Only:

In accordance to CSA International B149 installation

codes, the minimum allowed distance between the

combustion air intake inlet and the exhaust outlet of

other appliances shall not be less than 12 inches (305

mm).

IMPORTANT

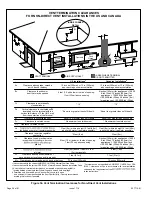

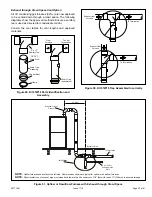

Details of Intake and Exhaust Piping

Terminations for Direct Vent Installations

NOTE:

In Direct Vent installations, combustion air is taken

from outdoors and flue gases are discharged to outdoors.

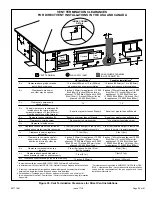

NOTE:

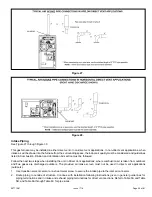

Flue gas may be slightly acidic and may adversely

affect some building materials. If any vent termination

is used and the flue gases may impinge on the building

material, a corrosion-resistant shield (minimum 24 inches

square) must be used to protect the wall surface. If the

optional tee is used, the protective shield is required.

The shield should be constructed using wood, plastic,

sheet metal or other suitable material. All seams, joints,

cracks, etc. in the affected area should be sealed using an

appropriate sealant. See Figure 44.

Intake and exhaust pipes may be routed either horizontally

through and outside wall or vertically through the roof. In

attic or closet installations, vertical termination through the

roof is preferred. Figure 36 through Figure 43 show typical

terminations.

1. Intake and exhaust terminations are not required to be

in the same pressure zone. You may exit the intake on

one side of the structure and the exhaust on another

side (Figure 37). You may exit the exhaust out the roof

and the intake out the side of the structure (Figure 38).

2. Intake and exhaust pipes should be placed as close

together as possible at termination end (refer to

illustrations). Maximum separation is 3” (76 mm)

on roof terminations and 6” (152 mm) on sidewall

terminations.

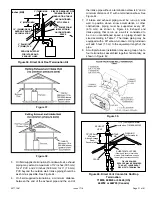

3. On roof terminations, the intake piping should terminate

straight down using two 90° elbows (see Figure 36).

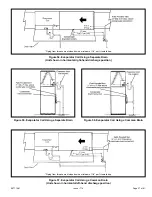

4. Exhaust piping must terminate straight out or up as

shown. A reducer may be required on the exhaust

piping at the point where it exits the structure to

improve the velocity of exhaust away from the intake

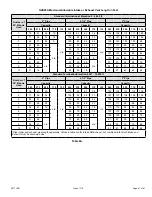

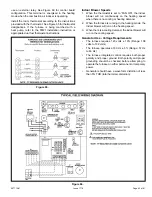

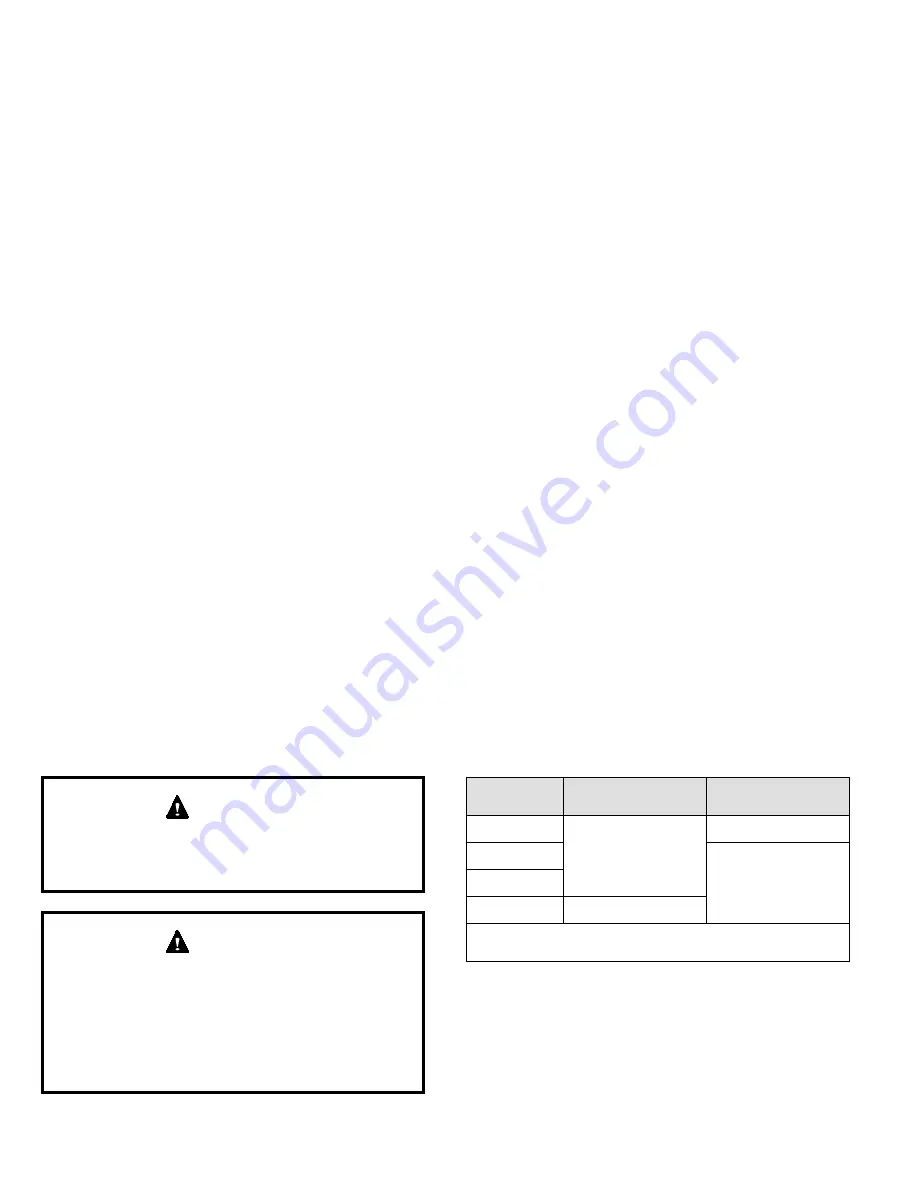

Table 8. Exhaust Pipe Termination Size Reduction

Capacity

Exhaust Pipe Size

Termination Pipe

Size

*045 and 070

2” (51 mm), 2-1/2”

(64 mm), 3” (76 mm)

1-1/2” (38 mm)

*090

2” (51 mm)

110

135

3” (76 mm)

* -045, -070, and -090 units with the flush mount termination

must use the 1 1/2” accelerator supplied with the kit.

NOTE:

Care must be taken to avoid recirculation of

exhaust back into intake pipe.