508146-01

Issue 2051

Page 5

4

of 7

0

Proper Combustion

Furnace should operate minimum 15 minutes with correct

manifold pressure and gas flow rate before checking

combustion. Take combustion sample beyond the flue

outlet and compare to the tables below.

The maximum

carbon monoxide reading should not exceed 100 ppm.

Unit

CO

2

% for Nat

CO

2

% for L.P.

All

7.6 - 8.6

9.1 - 10.1

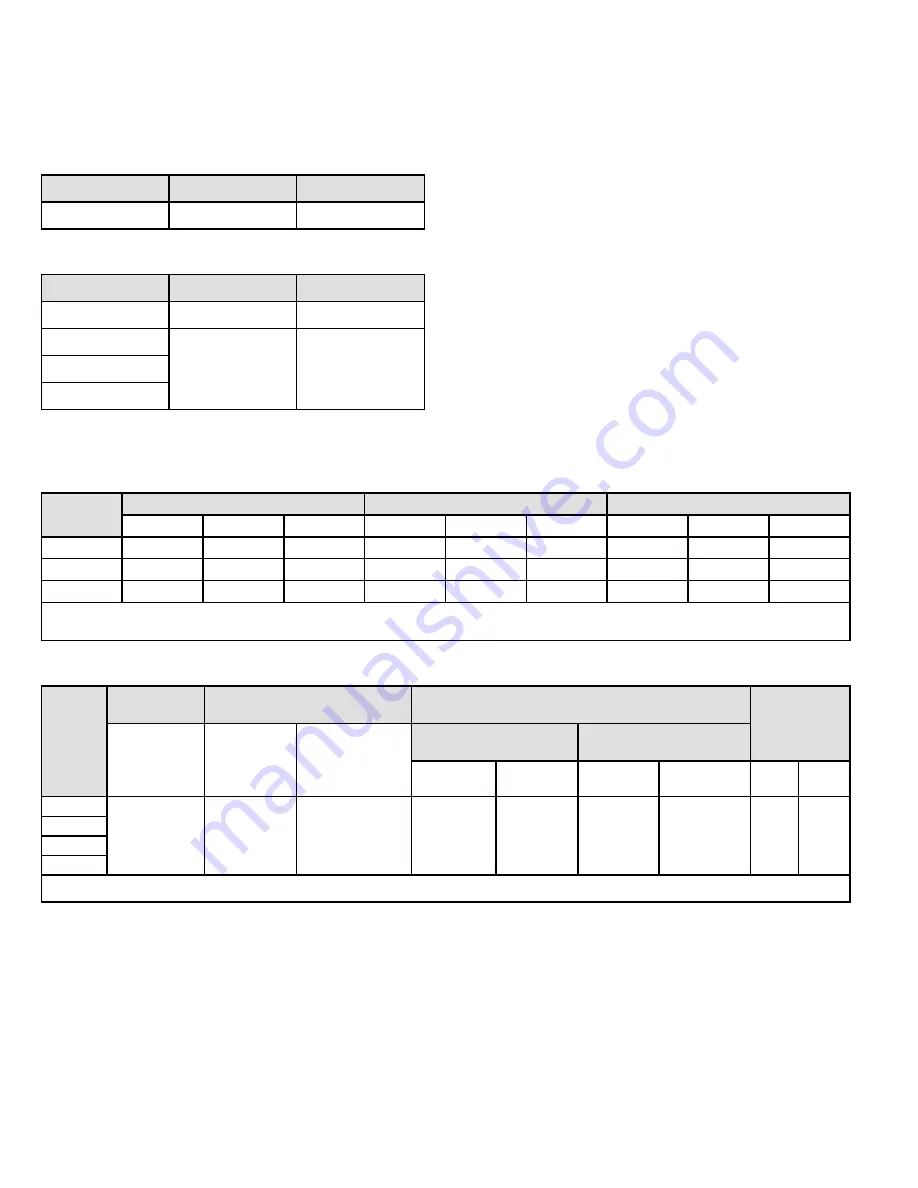

Table 27. High Fire

Unit

CO

2

% for Nat

CO

2

% for L.P.

070

5.7

7.2 - 8.2

090

5.3 - 6.3

6.8 - 7.8

110

135

Table 28. Low Fire

High Altitude

NOTE:

In Canada, certification f or i nstallations at

elevations over 4500 feet (1372 m is the jurisdiction of

local authorities.

GUH97M

units require no manifold pressure adjustments

for operation at altitudes up to 10,000 feet (3048m) above

sea level. Units installed at altitude of 7,501 to 10,000 feet

(2287 to 3048m) require a pressure switch change per Table

30. Table 30 also lists gas conversion kit requirements at

all altitudes.

The combustion air pressure switch is factory-set and

requires no adjustment.

Firing

Rate

Manifold Pressure Nat Gas

Manifold Pressure LP/Propane

Operating Pressure Signal (Delta P)

Min

Normal

Max

Min

Normal

Max

Min

Normal

Max

40%

0.5

0.6

0.7

1.3

1.6

1.9

0.25

0.30

0.35

70%

1.7

1.9

2.1

5.1

5.5

5.9

0.60

0.65

0.70

100%

3.2

3.5

3.8

9.5

10.0

10.5

1.10

1.15

1.20

NOTE

:

installation instructions for the conversion procedure.

Table 29. Manifold and Operating Signal Pressures in inches 0-7500 ft (0-2286 m)

Unit

LP/Propane

Kit

High Altitude Pressure

Switch Kit

Manifold Pressure at All Altitudes (in. w.g.)

Gas Orifice

Size

0 - 10,000

(0 - 3048 m)

0 - 7,500

(0 - 2286 m)

7,501 - 10,000

(2287 - 3048 m)

Low Fire

(35% rate)

High Fire

(100% rate)

Natural

Gas

LP/

Propane

Natural

Gas

LP/Propane

Nat

LP

070

68W77

Not required

14T65

0.40 - 0.60

1.2 - 1.8

3.2 - 3.8

9.5 - 10.5

.0625

.034

090

110

135

NOTE

:

The values given are measurements only. The gas valve should not be adjusted.

Table 30. Conversion Kit Requirements and Manifold Test Pressures