Comfortflame.US.com

900578-00_NC

10

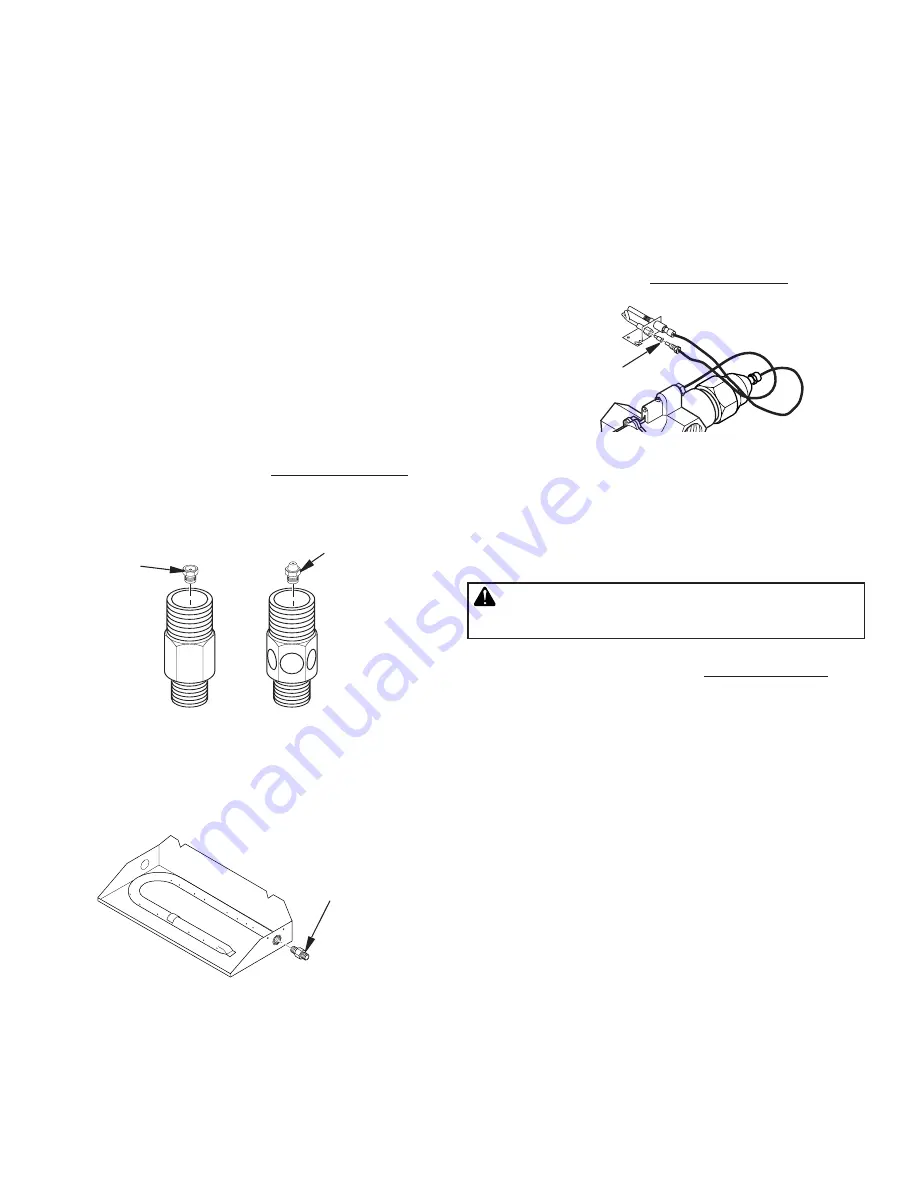

Figure 12 - Burner Inlet Fittings with Injectors

Figure 13 - Remove Burner Inlet Fitting

NATURAL

GAS

FITTING

PROPANE/

LP GAS

FITTING

Injector

for Natural

Gas

Injector for

Propane/

LP Gas

Burner Inlet

Fitting for

Natural Gas

INSTALLATION

Continued

PROPANE/LP GAS CONVERSION

To convert to propane/LP gas, burner inlet fitting and pilot orifice must

be replaced. Propane/LP burner inlet fitting is supplied with orifice

installed for a 24" log set. If you have an 18" or 30" set, you must

change this orifice also. See Figure 1, page 4 for product identification.

Burner Inlet Fitting

1. Remove burner inlet fitting from burner pan assembly. DO NOT

remove orifice from this fitting. Propane/LP burner inlet fitting is

included in hardware kit (see Figure 12).

2. Be sure to use correct orifice for your appliance. The hardware kit

included with this appliance contains two orifices with a cone-like

shape. If you have an 18" set, orifice for burner inlet fitting is red;

for a 30" set, it is black. If you have a 24" log set, orifice is already

installed inside fitting.

3. For an 18" or 30" set, use a 10 mm socket or nut driver to remove

orifice from propane/LP burner inlet fitting. Choose the correct orifice

for your log set size and install in place of orifice you just removed.

4. Using thread sealant (resistant to the action of propane/LP gas)

on larger end of fitting, screw burner inlet fitting through hole and

into burner manifold (see Figure 13). Tighten using a wrench.

5 . Follow steps 1 through 12 under Natural Gas Installation, pages

8 and 9.

Changing Pilot Orifice

The pilot is provided with a natural gas orifice installed. For propane/

LP gas you must remove it and replace it with an propane/LP orifice.

The accessory hardware kit contains an propane/LP orifice with a red

stripe for converting pilot.

1. Gently loosen and remove pilot line connection from bracket (see

Figure 14).

2. Replace injector (see Figure 14) with propane/LP pilot injector

with red stripe.

3. Replace and tighten pilot line to bracket.

4. Continue with step 3 under Natural Gas Installation, page 8.

TESTING BURNER FOR LEAKS

1. Generously apply noncorrosive leak detection fluid to all connec-

tions.

WARNING: Never check for gas leaks with open

flame.

2. Light burner with shutoff valve no more than half open and holding

a match slightly in front of pan (see Lighting Instructions, page

12).

3. Inspect all connections for bubbles, raw gas odor, or flame from

any area other than burner (leaks). If leaks are detected, shut off

gas valve immediately. Tighten, or reassemble loose connection(s)

using pipe joint compound until burner system is leak free.

4. When burner is tested and leak free, observe individual tongues

of flame on burner.

Note:

Burner design includes more ports on the outside of the

bar. Make sure that all ports are clear and producing flame evenly

across burner. If any ports appear blocked, clear them by removing

burner manifold and reaming ports with a modified paper clip or

other suitable tool.

5. When finished testing, turn gas shutoff valve OFF to extinguish

all flames.

ADDING PAN MATERIAL

1. Open bag of ash bed material (vermiculite) and spread it evenly

across burner pan to top. You may overflow front and sides of

pan to cover entire pan and connecting hardware. Do not cover

GA9050A-1 (F0235) or GA9150A (F0237) valve.

2. Open glowing embers and evenly cover ash bed material (ver-

miculite) in burner pan.

Figure 14 - Installing Propane/LP Pilot Orifice

Pilot Injector