Comfortflame.US.com

900578-00_NC

6

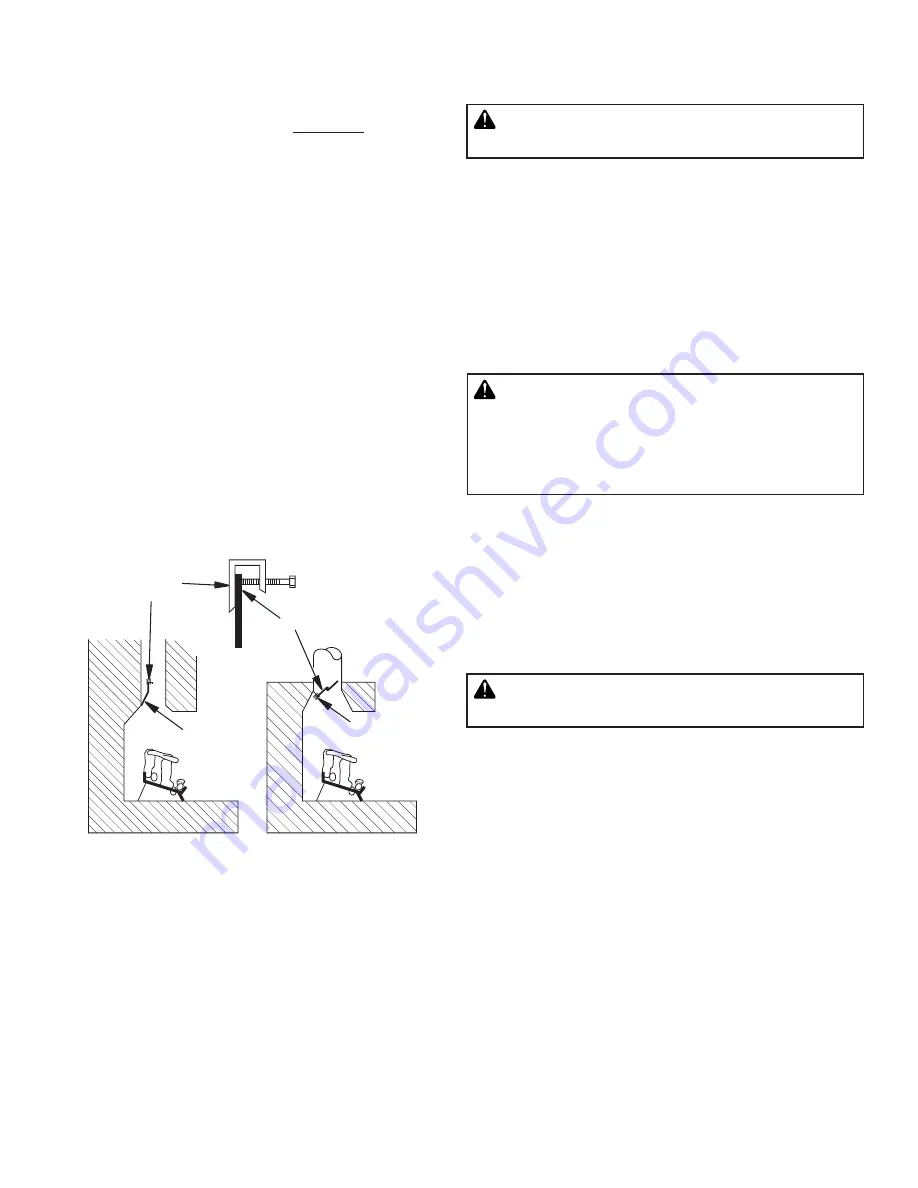

Figure 3 - Attaching Damper Clamp

Damper

Clamp

Damper

Clamp

Damper

Manufactured

Fireplace

Masonry Fireplace

Damper

CHECK GAS TYPE

Use only natural gas. If your gas supply is not natural gas, you must

install ON/OFF Safety Valve/Pilot Kit (see Accessories, page 17). Call

dealer where you bought log set.

If the fireplace does not have a gas supply shutoff valve, one must

be installed.

VENTING SPECIFICATIONS FOR INSTALLATION

The fireplace chimney flue and vent must be drafting properly. To

check the vent for proper drafting: Light a tightly rolled newspaper on

one end and place it at the inside front edge of the fireplace. Observe

the smoke and be sure the vent is properly drawing it up the chimney.

If the smoke spills out into the room, extinguish the flame and remove

any obstruction until proper venting is achieved.

The chimney flue must remain open a minimum of 3" at all times

during the operation of this log set.

For Massachusetts Residents Only

Installation of this vented gas log set in the Commonwealth of Mas-

sachusetts requires the damper be permanently removed or welded

in the fully open position.

INSTALLING DAMPER CLAMP

Secure the damper stop clamp provided to the leading edge of the

damper as shown in Figure 3. If for any reason this clamp doesn't

work on your fireplace, another suitable clamp or permanent stop

must be installed, or the damper blade must be cut or removed.

CONNECTING TO GAS SUPPLY

WARNING: A qualified service person must connect

log set to gas supply. Follow all local codes.

Installation Items Needed

Before installing log set, make sure you have the items listed below.

• piping (check local codes)

• sealant (resistant to Propane/LP gas)

• equipment shutoff valve

• test gauge connection

• adjustable (crescent) wrench or pliers

• sediment trap

• tee joint

• pipe wrench

CAUTION: Use only new, black iron or steel pipe.

Internally-tinned copper tubing may be used in certain

areas. Check your local codes. Use pipe of 1/2" diam-

eter or greater to allow proper gas volume to log set.

If pipe is too small, undue loss of volume will occur.

Installation must include a equipment shutoff valve, union, and

plugged 1/8" NPT tap. Locate NPT tap within reach for test gauge hook

up. NPT tap must be upstream from log set (see Figure 4, page 8).

IMPORTANT:

Install equipment shutoff valve in an accessible loca-

tion. The equipment shutoff valve is for turning on or shutting off

the gas to the appliance.

Apply pipe joint sealant lightly to male NPT threads. This will prevent

excess sealant from going into pipe. Excess sealant in pipe could

result in a clogged burner injector.

WARNING: Use pipe joint sealant that is resistant

to liquid petroleum (LP) gas.

We recommend that you install a sediment trap in supply line as

shown in Figure 4, page 7. Locate sediment trap where it is within

reach for cleaning. Install in piping system between fuel supply and

heater. Locate sediment trap where trapped matter is not likely to

freeze. A sediment trap traps moisture and contaminants. This keeps

them from going into log set controls. If sediment trap is not installed

or is installed wrong, log set may not run properly.

INSTALLATION

Continued