860479229

Instruction Sheet

www.commscope.com

Page 6 of 15

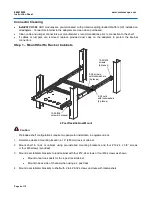

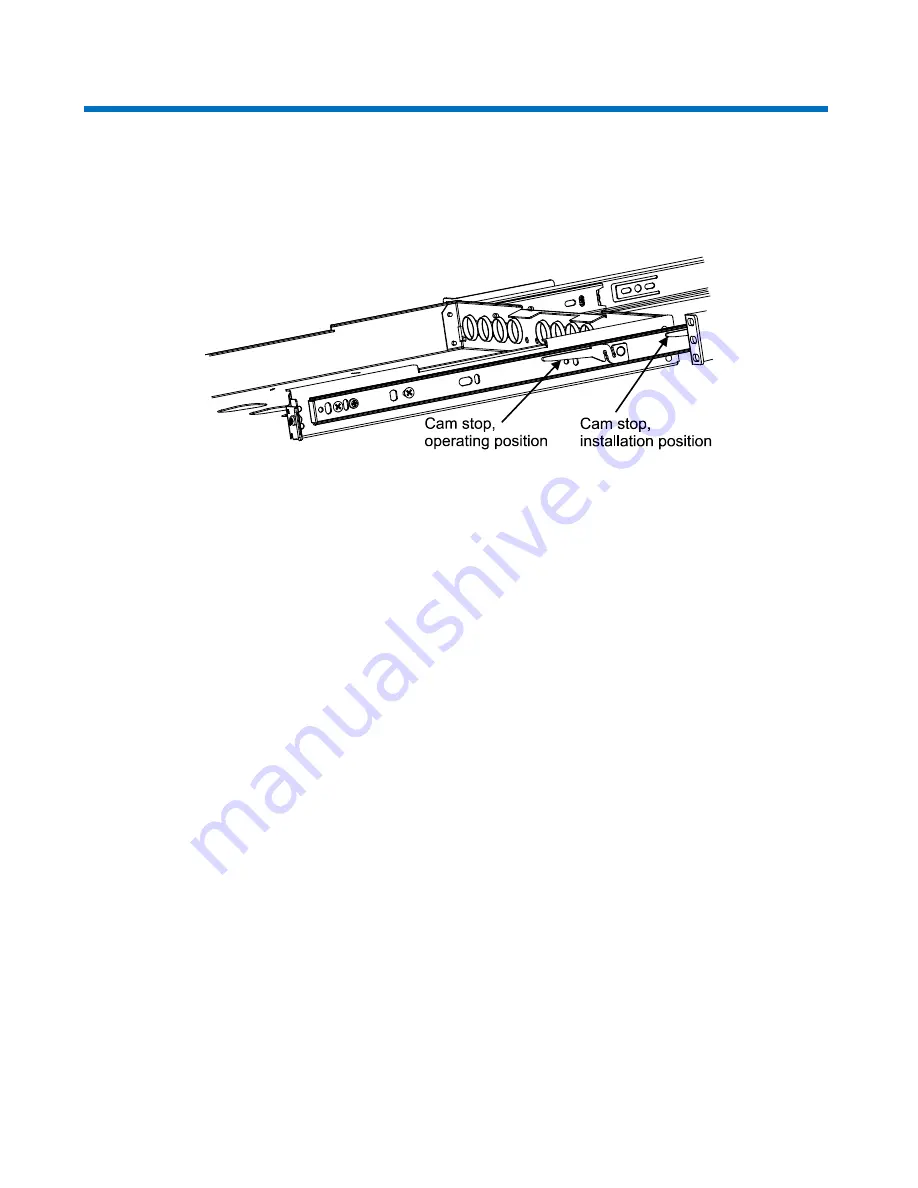

1. Fully extend sliding shelf to front of rack.

Note

: The shelf sliding mechanism incorporates two sets of position stops: one for normal operation and a

second for installation purposes. When pulling the shelf out, it will stop at the first operation cam stop.

Disengage this first stop by actuating the levers on both sides of shelf slide mechanism, allowing shelf to be

pulled out to its fully extended position for installation purposes as shown.

Shelf in Fully Open Position

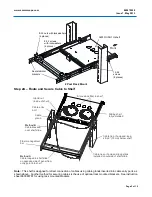

2. Cables may enter shelf from either right side, left side, or rear apron. Carefully loop cable to rear of shelf on

either side and continue to feed cable over top of rear apron.

3. Temporarily store slack fibers in shelf.

4. Remove plug from appropriate size opening in shelf to accommodate cable gland on cable. Select an

opening on rear apron or either right or left side panel that will be most advantageous for cable entry.

5. Completely loosen gland nut from cable gland.

6. Feed MPO connector(s) and subunit tube(s) through opening in shelf and temporarily coil fibers loosely in

fiber shelf.

7. Rotate gland nut as required to allow it to pass through selected opening and enter shelf.

Note:

It may be necessary to temporarily remove a plug from an adjacent opening to provide sufficient

clearance for gland nut to be inserted through opening.

8. Insert threaded body of cable gland into opening and tighten gland nut onto threaded section to secure cable

gland unit to shelf.

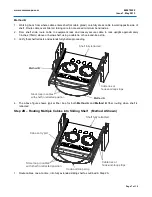

Note:

The two recommended methods (

Method A

and

Method B

) for routing fiber cable from sliding shelf to

equipment rack are described below.

Method B

routing requires a minimum of 1U open rack space above the

360

shelf.

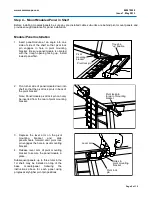

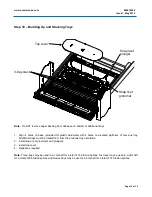

Method A

1. Working back from where cable enters shelf (at cable gland), carefully loop cable over rear fiber

management bar and then to outside of shelf slide on opposite side of panel from cable entry point as

shown. Maintain cable in as small of a radius as possible while not exceeding minimum bend radius for

cable. Secure cable to shelf slide in at least two places using cable ties or hook-and-loop strips threaded

through slots and punches provided in rails.

Do not secure cable to fiber management bar.

Note:

Do not exceed minimum bend radius for fiber cable.

2. From shelf slide, route cable to equipment rack and loosely secure cable to rack upright approximately

3 inches (76mm) above or below shelf, using a cable tie or hook-and-loop strip.

3. Verify that shelf retracts and extends fully before proceeding.