ADCP-96-167 • Issue 5 • July 2016

Page 25

© 2016, CommScope, Inc.

12. Align the gap in the grommet with the space between the clamp yokes and then

tighten the clamp screws evenly to 15 to 17 lbs-force inches (1.7 – 1.9 Nm) of

torque.

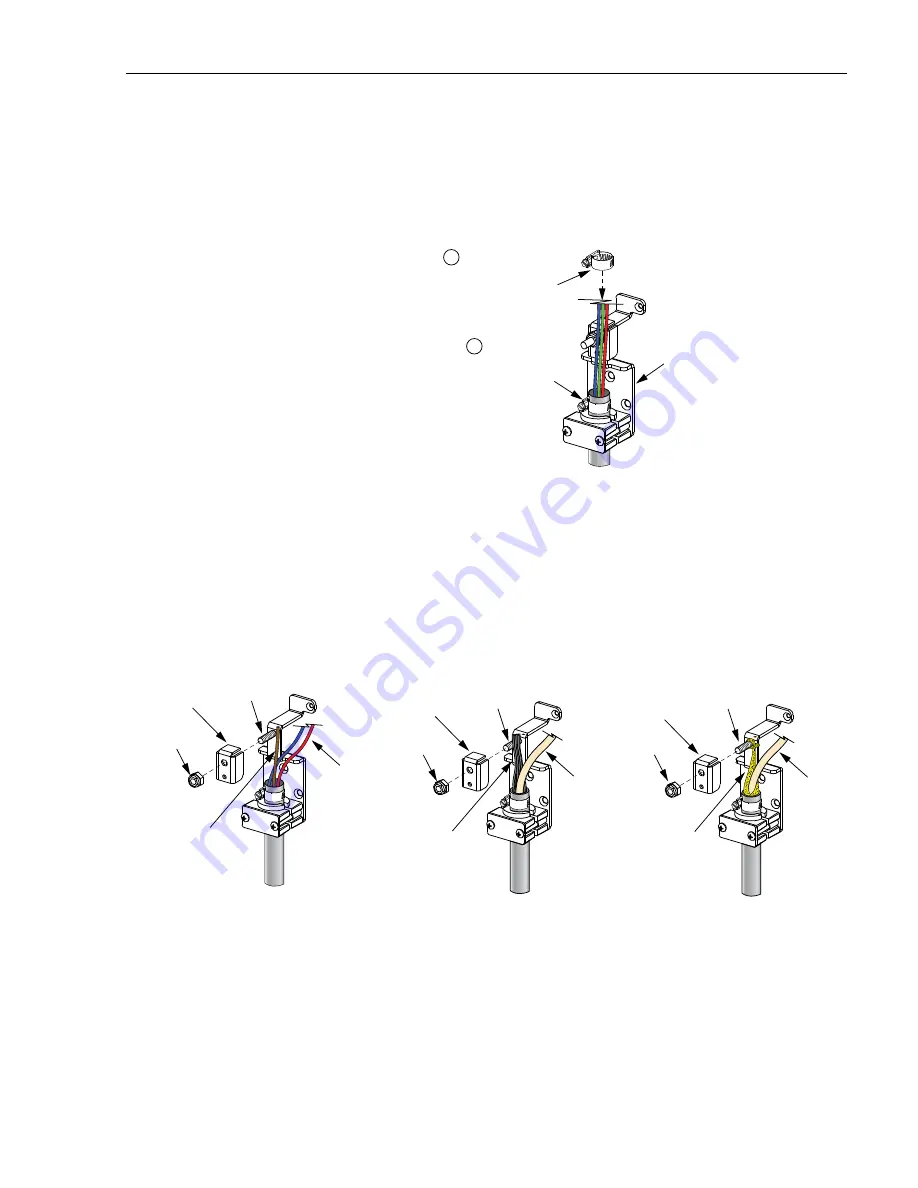

13. If a hose clamp was placed over the cable in step 11 (see

), tighten the

hose clamp to 17 to 19 lbs-force inches (1.7 – 2.1 Nm) of torque.

Figure 16. Hose Clamp Installation

14. Tighten the compression nut on the outside of the cabinet to secure the feeder

cable at the entry point into the cabinet.

15. Disassemble the cable strength member clamp as shown in

. For

stranded cable, the strength member will usually consist of a single element. For

ribbon cable, the strength member may consist of a stranded fiberglass sheath or

yellow synthetic fiber yarn.

Figure 17. Strength Member Clamp Installation

16. If installing cable with a single-element strength member (a), place the strength

member alongside the mounting bracket stud and cut the strength member so it is

flush with the top of the mounting bracket. If installing cable with a stranded

fiberglass sheath (b), gather the sheath together, place it alongside the mounting

24636-A

CLAMP

BRACKET

INSTALL HOSE CLAMP ON ALL OSP

CABLES AND ON ALL IFC CABLES

WITH A CENTRAL STRENGTH MEMBER

TIGHTEN HOSE CLAMP TO

17 - 19 LBS-FORCE INCHES

(1.7 TO 2.1 Nm) OF TORQUE

1

2

24318-C

SINGLE-ELEMENT

STRENGTH

MEMBER

*TIGHTEN NUT TO 35 LBS-FORCE INCHES (4.0 Nm) OF TORQUE

STRENGTH

MEMBER CLAMP

STRANDED

FIBER

BUFFER

TUBES

STUD

FIBER-GLASS

STRENGTH

MEMBERS

STRENGTH

MEMBER CLAMP

RIBBON

FIBER

TUBE

STUD

NUT*

NUT*

NUT*

STRANDED

CABLE

RIBBON

CABLE

RIBBON

CABLE

SYNTHETIC YARN

STRENGTH

MEMBER

STRENGTH

MEMBER CLAMP

RIBBON

FIBER

TUBE

STUD

(a)

(b)

(c)