Visit www.commscope.com for complete specifications on all the products listed

Bulletin # 7689527 Rev. G

Technical Publication

3

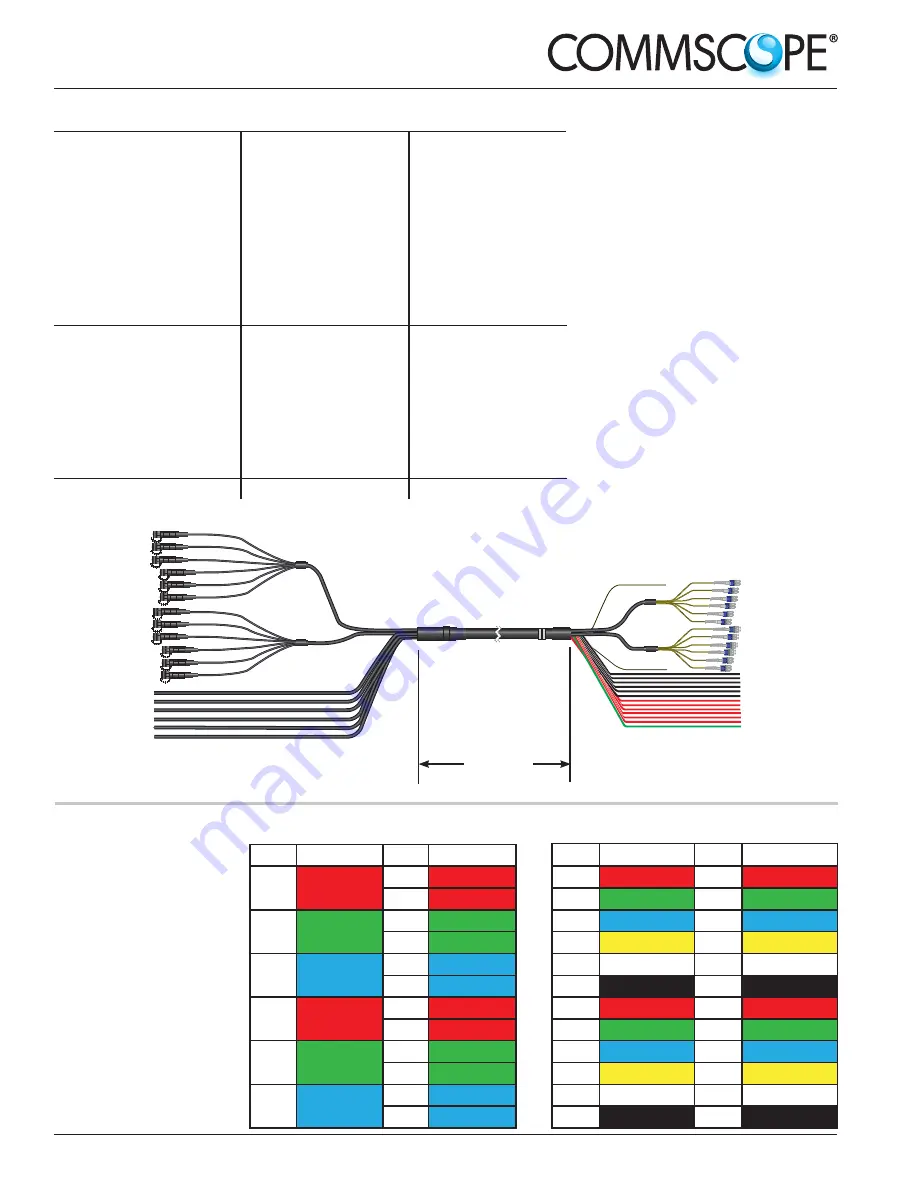

Color Coding

Power

End 1

Label Color

End 2

Label Color

1

RED

1

RED

1

RED

2

GREEN

2

GREEN

2

GREEN

3

BLUE

3

BLUE

3

BLUE

4

RED (X2)

4

RED

(X2)

4

RED

(X2)

5

GREEN (X2)

5

GREEN (X2)

5

GREEN (X2)

6

BLUE (X2)

6

BLUE (X2)

6

BLUE (X2)

Fiber

End 1

Color

End 2

Color

1

RED

1

RED

2

GREEN

2

GREEN

3

BLUE

3

BLUE

4

YELLOW

4

YELLOW

5

WHITE

5

WHITE

6

BLACK

6

BLACK

7

RED (X2)

7

RED (X2)

8

GREEN (X2)

8

GREEN (X2)

9

BLUE (X2)

9

BLUE (X2)

10

YELLOW (X2)

10

YELLOW (X2)

11

WHITE (X2)

11

WHITE (X2)

12

BLACK (X3)

12

BLACK (X3)

Cable Type

Brand

Center Conductor Gauge

Conductors, quantity

Total Fiber Quantity

Shielding Type

Fiber Type

Dimensions

Cable Weight

Diameter Over Jacket

Breakout Length, Fiber, end 1

Breakout Length, Power, end 1

Breakout Length, Fiber, end 2

Breakout Length, Power, end 2

Physical Specifications

Minimum Bend Radius, loaded

FDH1206-24SE2-XXX

HELIAX FiberFeed

UL Type TC-OF-ER

6 AWG

12

24

Solid copper tape

Singlemode fiber

2421 kg/km | 1627 lb/kft

36.2 mm | 1.43 in

1000 mm | 39 in

5000 mm | 196 in

1700 mm | 67 in

1700 mm | 67 in

723.9 mm | 28.5 in

FDH1210-24SE2-XXX

HELIAX FiberFeed

UL Type TC-OF-ER

10 AWG

12

24

Solid copper tape

Singlemode fiber

1050.0 kg/km | 705.5 lb/kft

25.14 mm | 0.99 in

1000 mm | 39 in

5000 mm | 196 in

1700 mm | 67 in

1700 mm | 67 in

502.9 mm | 19.8 in

Section 2: General Specifications

6x12 Configuration

ODC

compatible

connector

DLC

connector

End 1

RRU

End 2

BBU

Cable

Assembly

Length

Power

cords

Power

conductors