Technical Publication

(Continued)

Visit www.commscope.com/andrew for complete specifications on all the products listed

Bulletin # 7694293 Rev. A

6

LC Connectors and Adapter cleaning

Clean exposed connector ferrule by lightly moistening lint-free wipe with fiber optic cleaning solution (or >91%

isopropyl alcohol), and by applying medium pressure, first wipe against wet area and then onto dry area to clean

potential residue from end face. Clean connector ferrule inside adapter by inserting lightly moistened cleaning stick

with fiber optic cleaning solution (or >91% isopropyl alcohol) inside the adapter until contact is made with connector on

opposite end. Rotate cleaning stick with medium pressure in one circular motion as it is pulled away from the adapter.

Repeat process using dry cleaning stick.

Caution:

Signal strength will be affected if end and sides of ferrule are not thoroughly cleaned. Discard cleaning

sticks after each use. Do not turn cleaning sticks back and forth pressing against connector end face. This may cause

scratches if large contamination is present. Always inspect connector end face for contamination after each cleaning.

Clean adapter by inserting adapter cleaning stick (or fiber adapter sleeve brush) moistened with fiber optic cleaning

solution (or >91% isopropyl alcohol) inside the adapter and gently pull out with twisting motion. Repeat process with a

dry cleaning stick.

Caution:

Do not try to clean adapter with a standard pipe cleaner. The sleeve inner diameter of LC adapters is too

small. Do not try to clean the adapter with cleaning stick if a connector is mounted in one side. Discard cleaning sticks

after each use.

Clean Tip of Ferrule

Clean Sides of Ferrule

Adapter Brush

Breakout Procedure

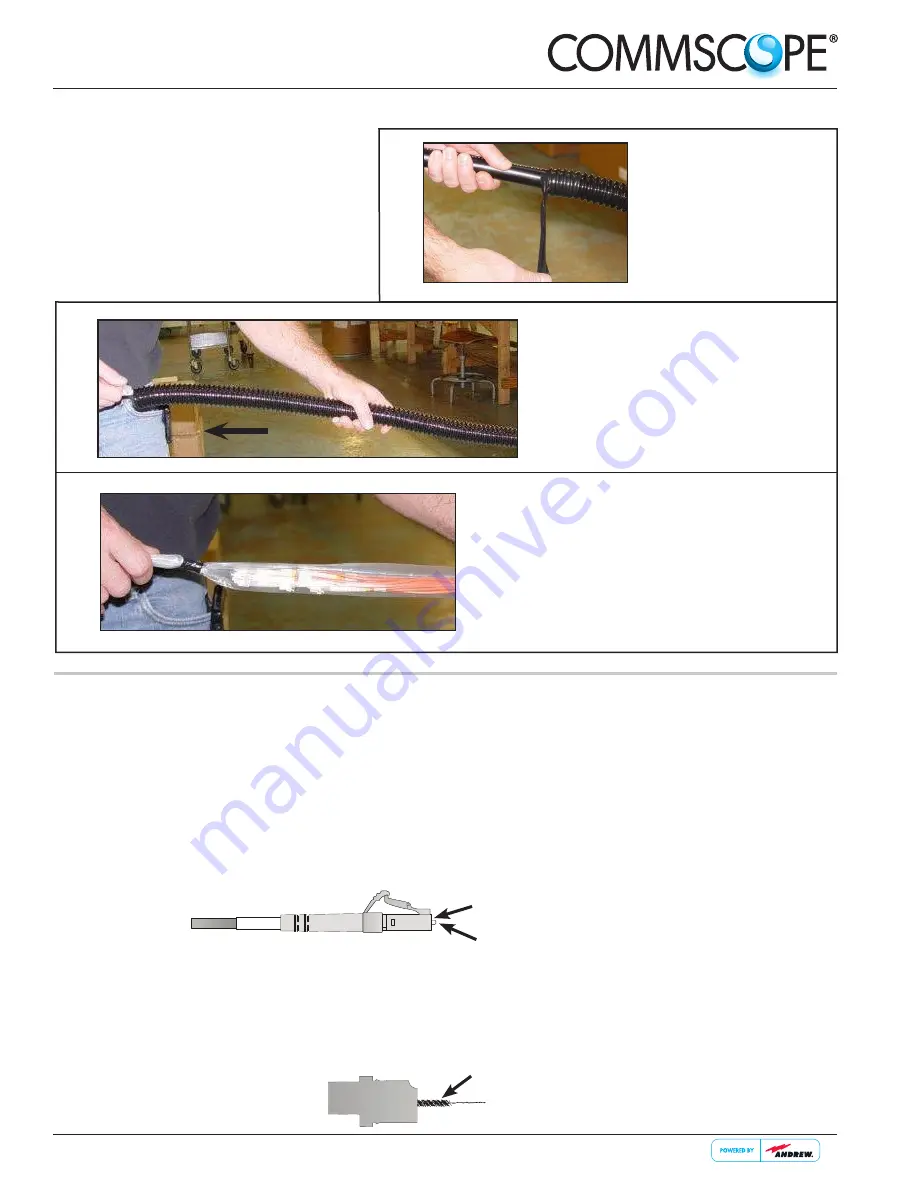

Remove electrical tape

from the trunk cable and

corrugated protection

tube

1

2

3

While holding the protection tube straight

pull the tube away from cable.

After you have pulled the fiber and power

conductors into the OVP box remove electrical

tape from the trunk cable and remove clear tube

for access to all optical connectors.

After the trunk cable has been installed and

you are ready to make the final connection

to the OVP box follow these steps for the

removal of fiber protection tube.