HR300 SERIES DEHYDRATOR USER MANUAL

Page

9

of

12

The first compressor will start and air will begin

flowing to the transmission line(s).

If this is a new installation, the transmission

lines must be purged by creating a small leak at

the far end of the transmission lines and

allowing the dehydrator to pump dry air through

them.

A minimum of three air volume exchanges is

required. If the installation is located in a very

humid area, up to twelve air exchanges may be

necessary to properly purge the transmission

line. The time, in hours, necessary to exchange

the air one time is based on the total air volume

(V) of the waveguide and antenna system.

Purging time (hours) = (3 x V) / 300, where V is

line volume in liters

At the conclusion of the purging cycle, close the

far end of the transmission lines.

5.6

Alarms

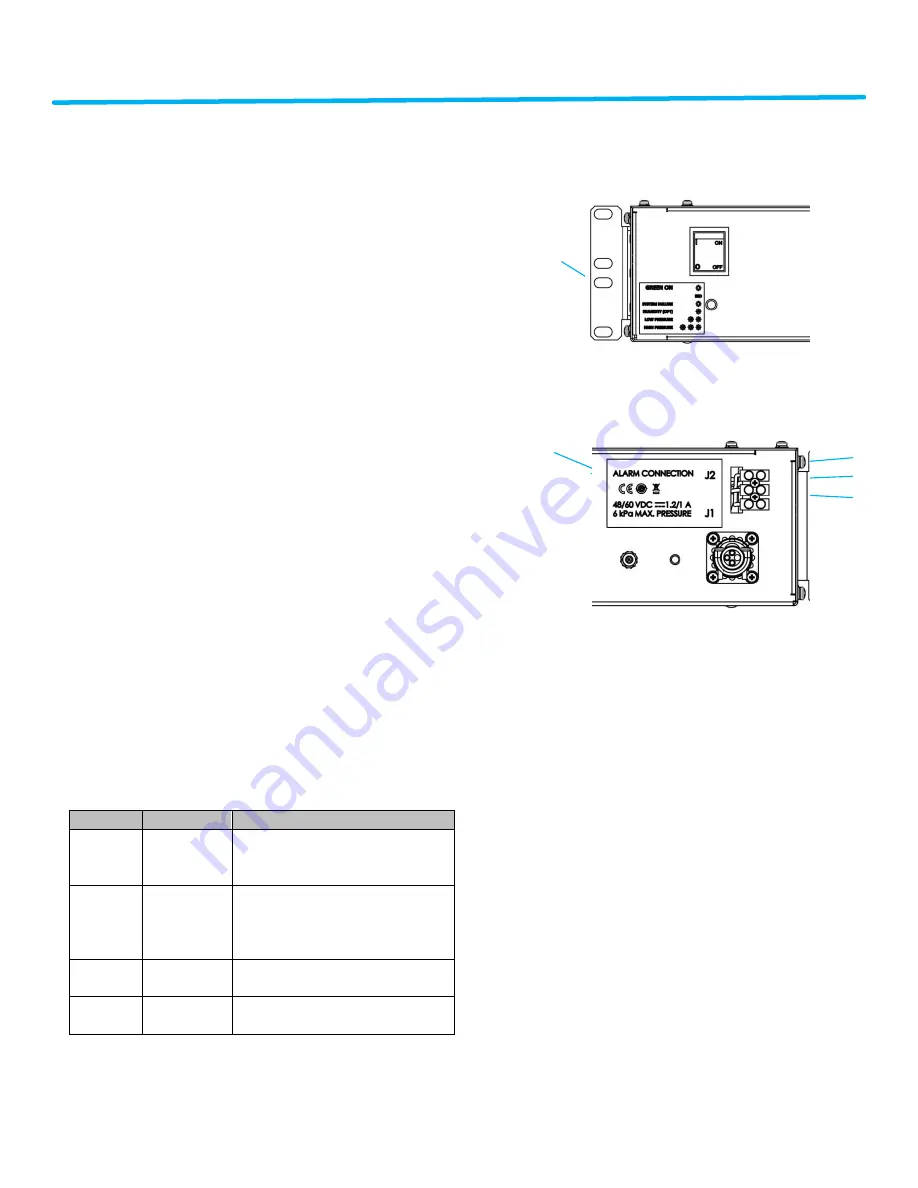

The HR300 is equipped with an LED on the front

panel for a visual indication of alarm conditions.

A green LED indicates all is well with the

dehydrator. A solid or blinking amber LED

indicates a problem with the dehydrator.

Blinks

Alarm

Description

Solid

Amber

System

Failure

Indicates a failure of the

controller. Replacement will be

necessary.

1

High

Humidity

(optional)

Indicates output air is above 10%

RH. This can be caused by long

storage periods and should clear

in the first 24 hours of operation.

2

Low

Pressure

Indicates a system pressure

lower than alarm threshold.

3

High

Pressure

Indicates a system pressure

higher than alarm threshold.

If multiple alarms exist at the same time, they

will blink in sequence with approximately two

seconds between.

Front of Chassis

Rear of Chassis

Section 6

Corrective Maintenance and Spare

Parts

The HR300 is designed to be maintenance free.

If you experience any issues with the HR300,

please contact CommScope. See Section 8 for

additional information.

ALARM

SYMBOLS

ALARM

OUTPUT

WIRES COLORS

BLACK (NO)

WHITE (COM)

RED (NC)