Page 41

Manual ION-M7P-7P-85P-19P

MF0145A4A.doc

6.2.

SPECIFICATIONS

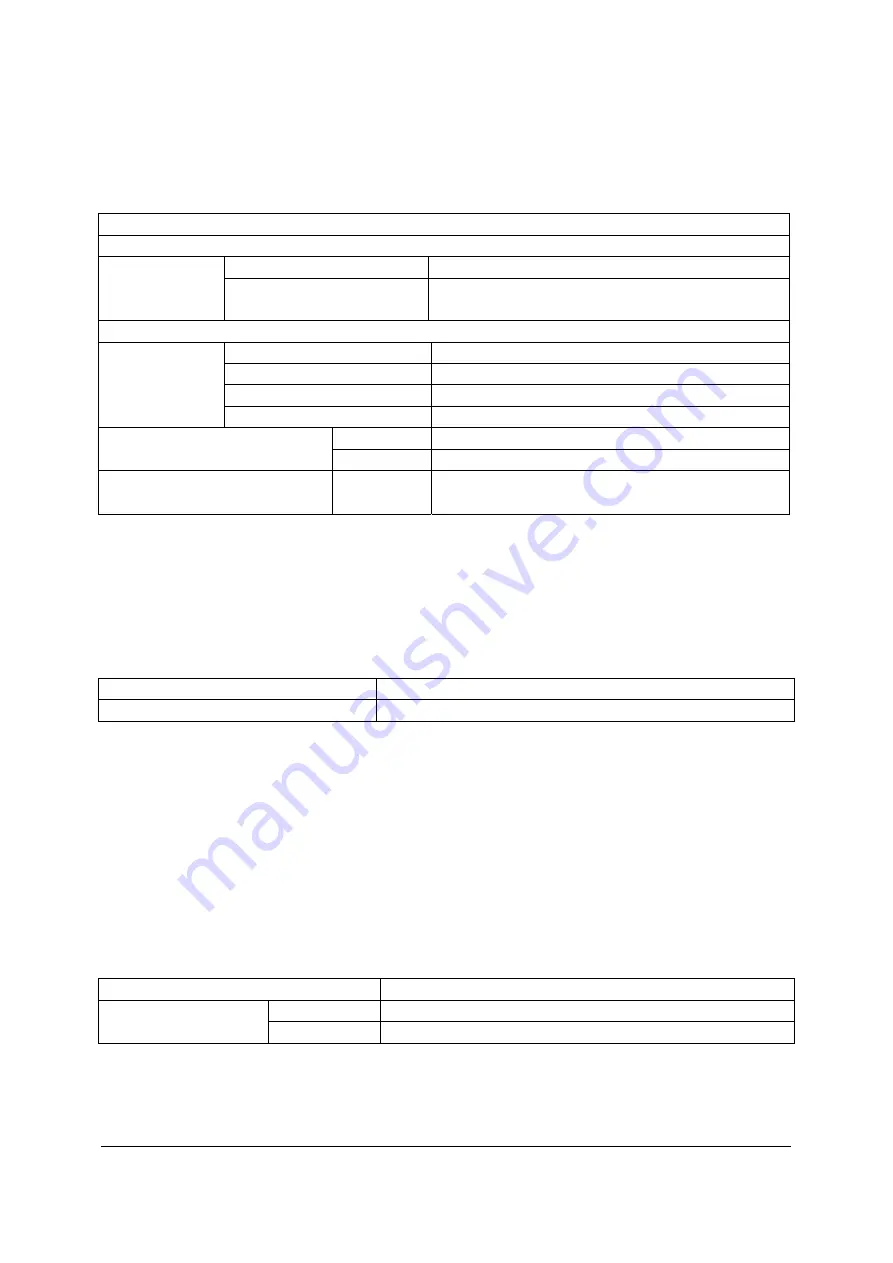

6.2.1. Electrical Specifications

ION-M7P/7P/85P/19P

Electrical

Mains power

115 Vac or 230 Vac

Power supply

Power consumption

1100 Watts max.

< 750 @ normal operation

Optical

Connectors E2000/APC

8°

Optical return loss,

45 dB

Fibre type

Single mode E9/125 µm

Optical link

Optical link budget

0 dB to 10 dB

850 MHz

3.0 dBm composite

Composite input power @

OTRx master side

1900 MHz

3.0 dBm composite

Input power range

7P/7P

-15 dBm to +14 dBm

7 dBm nominal

All figures are typical values, unless otherwise stated.

All data is subject to change without notice.

6.2.2. Mechanical Specifications

Height, width, depth *

817 x 245 x 218 mm (32.2 x 9.6 x 8.6 in)

Weight

40 kg (88.2 Ib)

*

Spacing required 40 mm (1.58 in) around unit

All data is subject to change without notice.

6.2.3.

Environmental and Safety Specifications

Note:

For detailed information, please refer to the Environmental and

Safety Specifications leaflet of the supplier, related to ETS 300 019

(European Telecommunication Standard).

Operating temperature range

-33 to +50°C

RF part

IP67

Ingress protection

Fan part

IP55

All figures are typical values, unless otherwise stated.

All data is subject to change without notice.