User’s Manual for

Remote Unit ION™-M80/90/19P

Page 18

MF0133ABA.doc

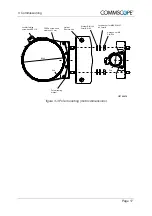

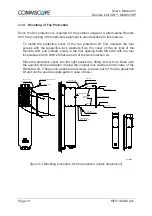

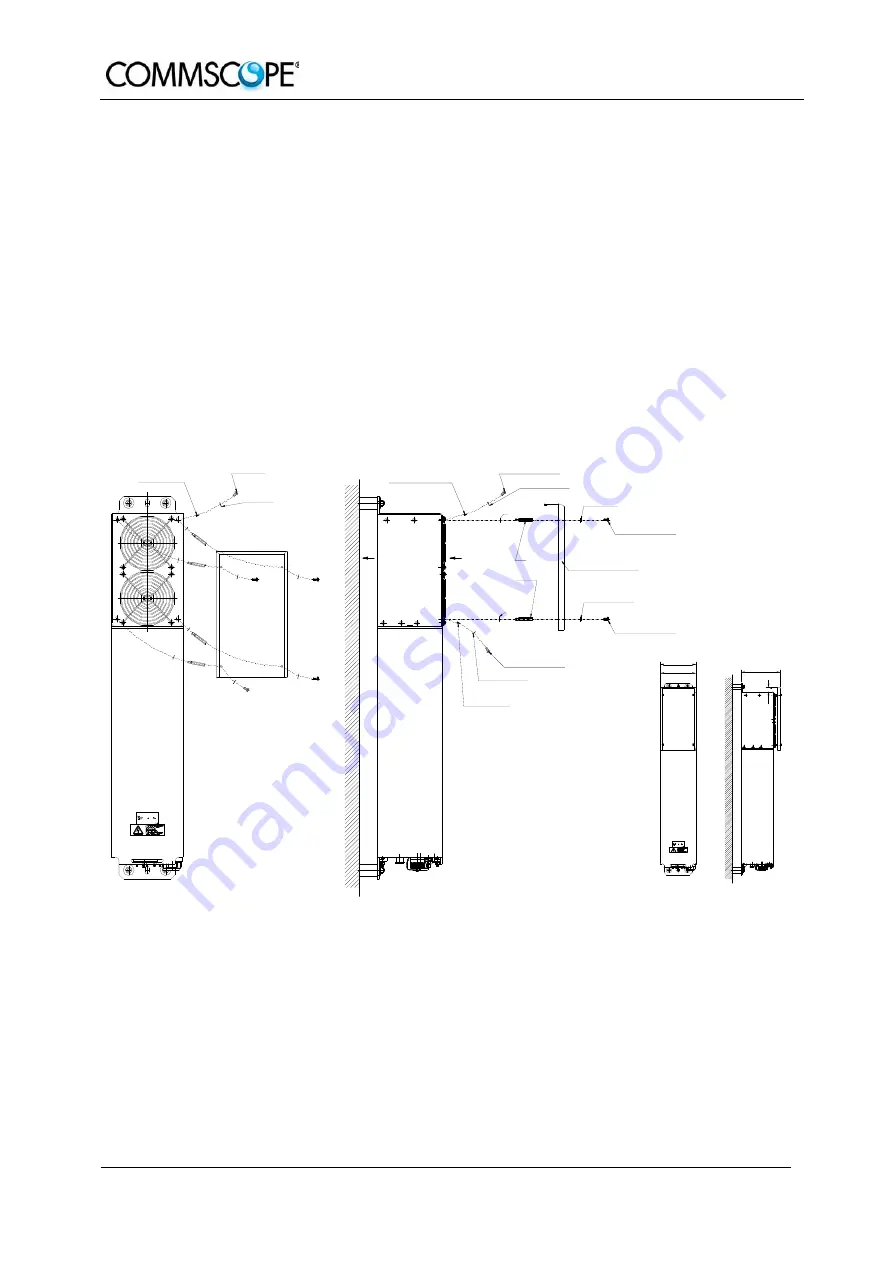

3.1.4. Mounting of Fan Protection

Since the fan protection is required for the outdoor usage of a stand-alone Remote

Unit, the mounting of this optional equipment is also described in this manual.

To install the protective cover of the fan protection kit, first unscrew the four

screws with the respective lock washers from the cover of the air inlet of the

Remote Unit, and instead, screw in the four spacing bolts M4.0x30 with the four

lock washers M4.0 DIN125 that are part of the fan protection kit.

Place the protective cover into the right position by fitting its four bore holes over

the spacing bolts and fasten it using the original lock washers and screws of the

Remote Unit. (These lock washers and screws are also part of the fan protection

kit and can be used as spare parts in case of loss.)

2x M4.0x8

fillister-head screws

2x lock washers

remove the screw

and the lock washer!

2x lock washers

2x M4.0x8

fillister-head screws

remove the screw

and the lock washer!

2x M4.0x8

fillister-head screws

1x rain protective cover

2x lock washers

2x M4.0x8

fillister-head screws

2x M4.0x8 fillister-head screws

2x lock washers

remove the screw

and the lock washer!

2x washers

2x washers

156

152

171

20

AIR STREAM

2x M4.0x30

spacing bolts

G0496MF

figure 3-4 Mounting procedure for fan protection (metric dimensions)