www.commscope.com

860452168

Instruction Sheet

Page 13 of 21

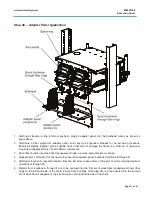

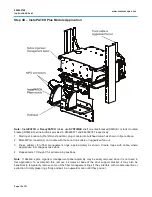

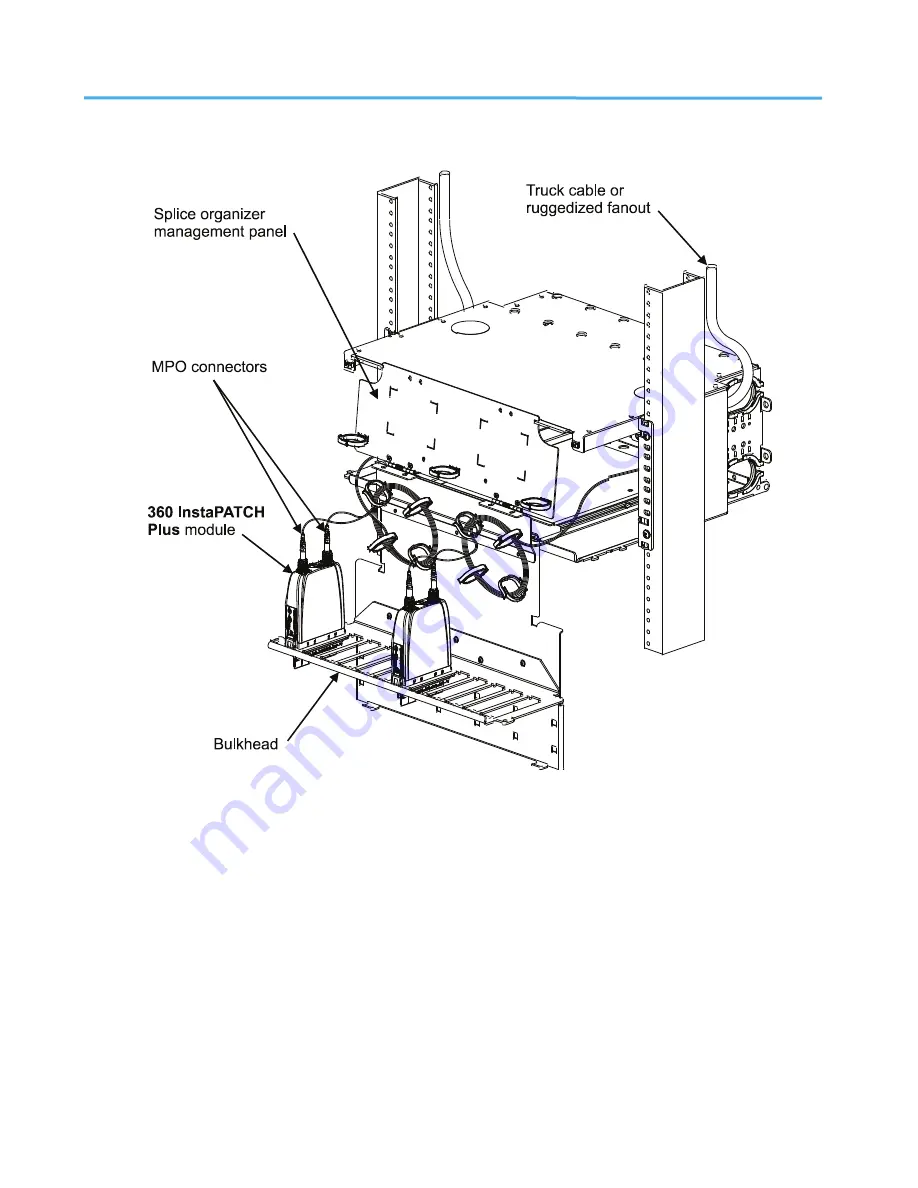

Step 4E – 360 InstaPATCH Plus Module Application

Note: InstaPATCH

or

ReadyPATCH

cables use

SYSTIMAX

shelf mounted bracket (SMB) kit or rack mounted

bracket (RMB) kit per instructions provided in 860448471 and 860380781 respectively.

1. Starting at location A (the left-most position), plug module into bulkhead cutout, as shown in figure above.

2. Mate MPO connector(s) on module with those on trunk cable or ruggedized fan out.

3. Dress cable(s) thru fiber management rings, approximately as shown. Create loops with cable, where

appropriate, to manage excess slack.

4. Repeat items 1 through 3 for all remaining positions.

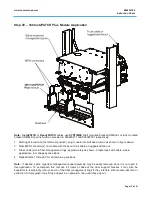

Note

: If desired, splice organizer management panel assembly may be easily removed since it is not used in

this application. To accomplish this, remove 4 screws at base of the door support bracket. It may also be

beneficial to temporarily remove some of the fiber management rings if they interfere with module insertion or

extraction. Simply grasp rings firmly and pull in an upward motion until they pop out.