Page 2 of 9

© 2021 CommScope, Inc. All Rights Reserved

3

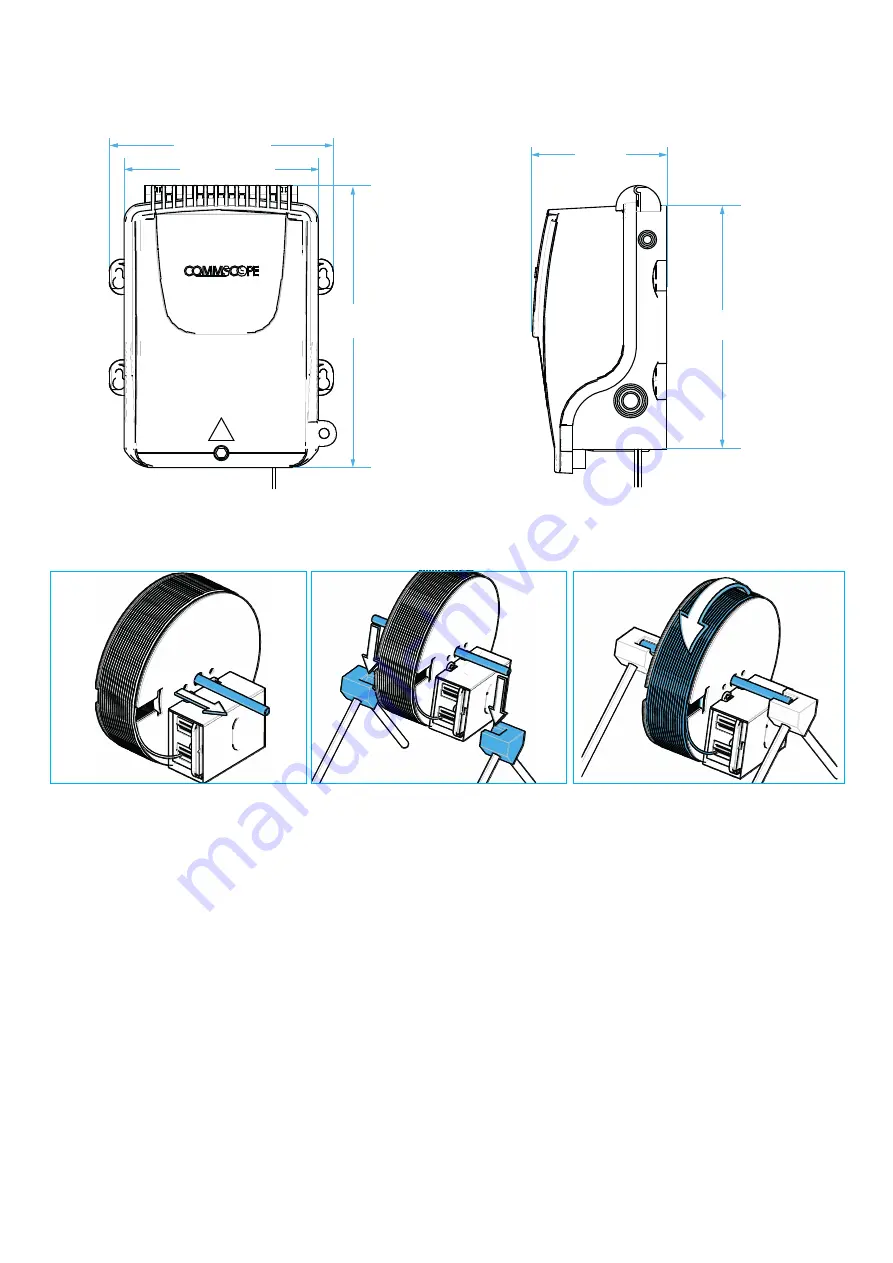

Determining where to mount the BUDI-R

The BUDI-R should be mounted in the MDU or MTU near the entry to the conduit or duct that the cable will be routed

through to the local hub. Figure below shows the BUDI-R dimensions.

4

Unpacking the external spool (if applicable)

Note:

Pulling bar and stand not included in the kit.

4.1

Insert the pulling bar through the spool. The BUDI-R is attached to the spool with cardboard connections and cable

ties.

4.2

Place it on the stand as shown.

4.3

Spool is ready to pay out.

5

Paying out the cable on external spool (if applicable)

Caution:

The cable is not designed for outdoor direct burial or outdoor aerial applications. Do not pull fiber perpendicular

from the BUDI-R. Pull fiber parallel with the wall and route to the equipment.

5�1

Preparing the MPO cable

Note:

This procedure assumes use of a pulling swivel mesh to pull the connector through to the termination point.

Note

: Pulling swivel is not included in the kit.

214 mm (8.4 IN.)

277 mm

(10.9 IN.)

185 mm (7.3 IN.)

214 mm

(8.4 IN.)

228 mm

(8.9 IN.)