6-7-06 - Fifth Proof

3-12

Pre-Start Inspection and Operation

Machine Travel Controls

• Levers and controls should return to the neutral position when they are released.

• Make sure that all of the controls are in the neutral (middle) position before starting the

engine.

• Operate the controls gradually and smoothly. Excessive speed and quick control movements

without regard for working conditions could cause an unsafe situation.

• Make sure to maintain your grip on both of the hand grips any time the machine is in motion.

NOTE:

If your machine is equipped with a track drive system, additional safety systems have

been built into the track drive. Due to the spring tension system built into the track drive system

as a safety mechanism, the machine can be put into an extreme situation during which the drive

sprocket will bypass the rubber track guide holes causing a popping noise, called “cogging”.

This situation is part of the track drive systems safety design, and indicates that this portion of

the safety system is functioning properly. The “cogging” condition is most likely to occur while

operating in a reverse direction pulling a heavy load, and during the first 50 hours of track

usage. It is caused by the tension spring being fully compressed due to high track load. If a

cogging condition occurs, immediately stop machine travel and auxiliary functions and reverse

travel direction slightly to de-compress track tension. Continued cogging will cause the track

drive sprocket to seat into the rubber track incorrectly, and cause damage to the track. If

cogging occurs, stop travel function and check for and remove any debris or foreign matter in

the drive system, check track for proper tension as shown in Section 4 of this manual, and

resume operation.

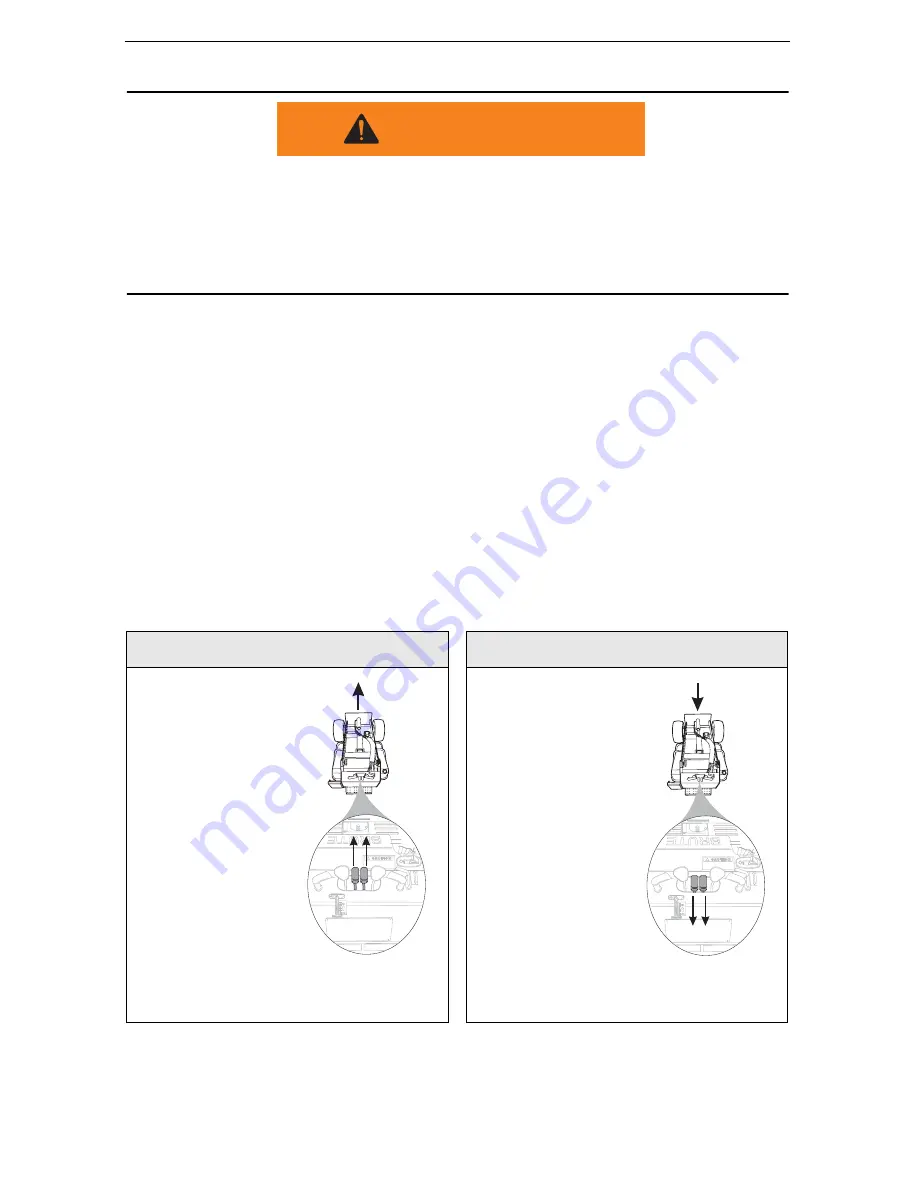

Forward Travel

Reverse Travel

Push both control

levers forwards to

travel straight

forward. The

farther these are

moved, the faster

the machine will

travel. See Figure

3–12.

2135

Figure 3–12

Forward Travel

Pull both control

levers backwards

to travel straight

backwards. The

farther these are

moved, the faster

the machine will

travel. See Figure

3–13.

2136

Figure 3–13

Reverse Travel

WARNING

Summary of Contents for BOXER 427 Operators

Page 2: ...6 7 06 Fifth Proof...

Page 6: ...6 7 06 Fifth Proof iv Mertz Manufacturing LLC P O Box 150 Ponca City OK 74602 Affix Stamp Here...

Page 8: ...6 7 06 Fifth Proof vi...

Page 18: ...6 7 06 Fifth Proof 1 8 Safety Precautions...

Page 31: ...6 7 06 Fifth Proof 3 5 Pre Start Inspection and Operation Figure 3 4 Lubrication Points 2128...

Page 52: ...6 7 06 Fifth Proof 3 26 Pre Start Inspection and Operation...

Page 74: ...6 7 06 Fifth Proof 4 22 Routine Service and Maintenance...

Page 85: ...6 7 06 Fifth Proof...