CompAir UK Ltd

PUBLICATION 98407/1050

Page 22

6.2 UNPACKING

Unless the compressor set is delivered uncrated, certain components, e.g. anti-vibration To avoid

the loss of these items they should be located and removed first. After unpacking, fit any items

which were loose in the crate and are now required for installing the set. To refit anti-vibration

mounts (if supplied), first read the information under

HANDLING

(section3.3

below), then raise the

set on to suitable supports and fit mounts by means of attached stud or setscrew

Any protective blanks fitted to the compressor ports should not be removed until making the

pipework

connections.

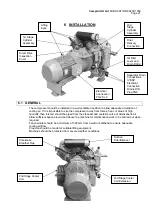

6.3 HANDLING

A guide to the weight of the unit is given in Section 2. Before attempting to move the set, ensure

that the available lifting equipment is of suitable capacity. When lifting by crane or hoist, sling the

unit with ropes or chains under the compressor baseplate and ensure by use of a spreader, that

the lifting tackle is held clear of any compressor components such as switches and belt guard etc.

6.4 MOUNTING

Seating must be level and designed to support the weight and any out of balance forces. Unless

flexible mounts are being used shims should be placed where necessary to ensure that the

bedplate is not strained out of alignment when the holding down bolts are finally tightened.

6.5 DRIVE

Compressor is suitable for direct or belt drive application. When belt driven ensure that driving and

driven pulley grooves are in line and shafts are parallel, before and after installation Tensioning

procedures follow normal practice. (See B.S. 3790 1981). See SECTION 10 for details on DIRECT

DRIVE>

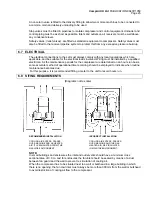

6.6 CONNECTIONS,

PIPEWORK AND FITTINGS

Careful thought should be given to the system and piping lay-out with all piping and connections

suitable for the pressures and capacities involved.

If flexible mountings are to be used under the bedplate, then pipes and electrical cable to and from

the compressor must have adequate flexibility.

Suitable joints should be made in the connecting pipes so that only a short length of pipe need be

removed to allow the compressor to be dismantled during overhaul.

Before assembly of pipework is completed, ensure that all port protection plugs and blanks are

removed.

Ensure all pipes are free from jointing compound, pipe scale, swarf, dirt and other foreign matter,

especially if suction piping is used.

All pipework must be suitably supported to prevent vibration so that no undue strain is placed on

the compressor.

A suction filter must always be fitted to prevent damage and excessive wear. When the filter is

remote from the compressor, the suction ducting must be of sufficient strength to prevent damage

being caused by the pulsating suction pressure. Additionally when the compressor is installed on

anti-vibration mountings, it should have sufficient flexibility to absorb a small degree of movement.

To protect the machines from excessive temperatures, either a fusible plug or temperature

cut-out switch should be fitted to the machine outlet (delivery).

An aftercooler is fitted to avoid high temperature discharge air being delivered into the system

receiver.

Extra separators and drain traps must be of adequate capacity and arranged so that they can be

drained regularly. When delivering into an air main it is recommended that the delivery pipe

connects into the top of the air main delivery pipe.

Summary of Contents for 5211.2.IA

Page 2: ......

Page 14: ...CompAir UK Ltd PUBLICATION 98407 1050 Page 12...

Page 16: ...CompAir UK Ltd PUBLICATION 98407 1050 Page 14 REMARKS DATE REMARKS DATE...

Page 22: ...CompAir UK Ltd PUBLICATION 98407 1050 Page 20...

Page 32: ...CompAir UK Ltd PUBLICATION 98407 1050 Page 30...

Page 38: ...CompAir UK Ltd PUBLICATION 98407 1050 Page 36...

Page 61: ......