App 408 Customer PET controller installation guide & user's manual

Page 12

App 408C

98155.1015

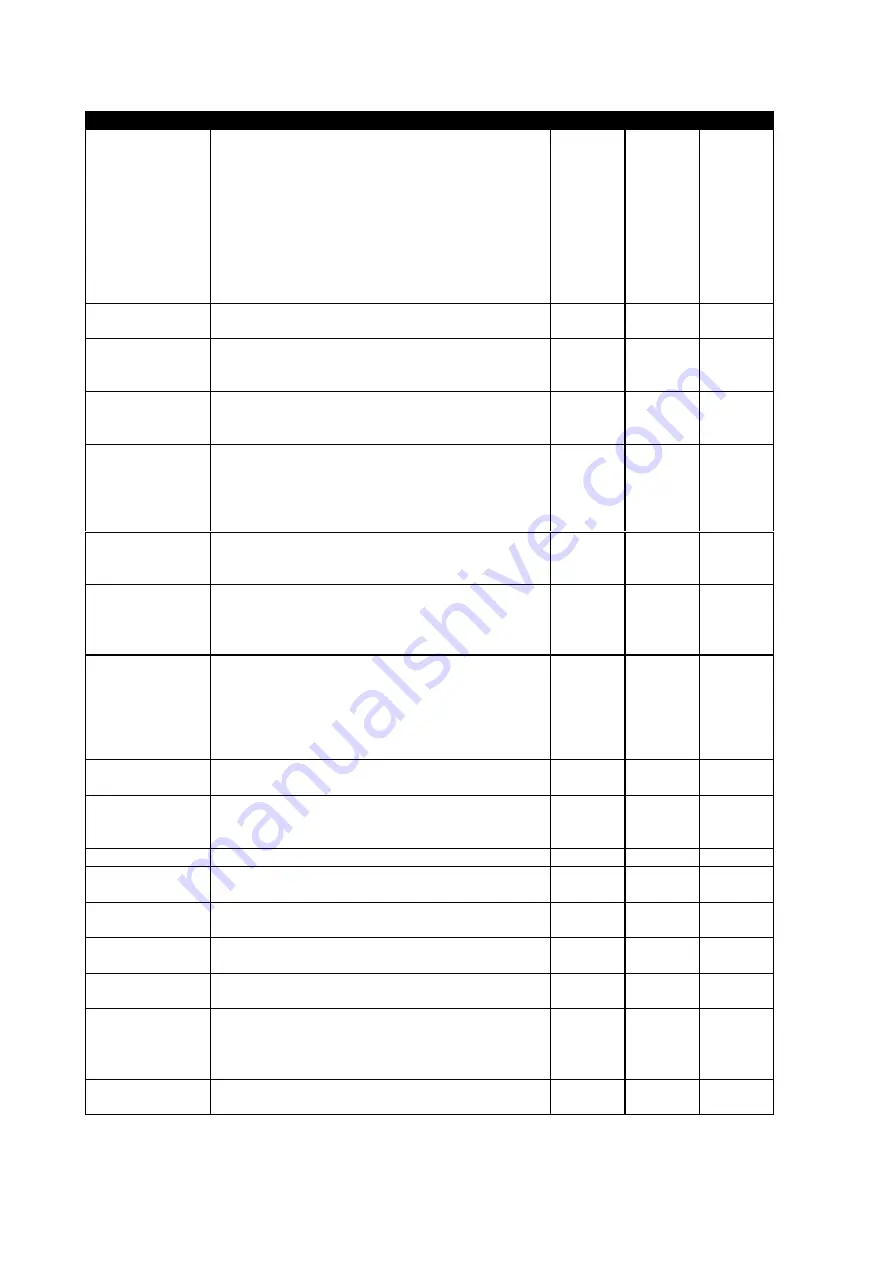

Parameter

Function

Default

Min.

Max.

Starts/hour

This safety feature prevents the compressor

from starting too often in order to protect the

motor against overheating. The controller uses

an advanced start per hour handling program

and when the limit of the number of starts is

reached it will prevent the motor from stopping

when running unloaded.

NOTE

The system does not prevent manual

start/stops but takes them into account when

running automatically.

6

3

10

Water flow

delay

The time that the water flow digital input fault is

overridden after ½ load is engaged.

20s

1s

60s

Star delta

The star-delta time is the transition time when

passing from the star relay to the delta relay.

This can also be used for soft start.

5s

3s

30s

ST-delt dl

The star-delta delay time is the time between the

release of the star relay and the powering of the

delta relay.

50ms

10ms

100ms

Accel time

( Load delay

time)

The acceleration time is the time between the

powering of the delta relay and the powering of

the load solenoid valve. The delay is to ensure

adequate lubrication before the compressor

goes on load.

30s

10s

60s

Minimum

unload time

The minimum unload time determines the

minimum time that the compressor has to run

unloaded before switching again to load.

5s

1s

60s

Unloaded run

time

The unloaded run time is the time that the motor

keeps on running after the stop button has been

pushed. This is to release condensate before

the compressor stops

60s

1s

120s

Blowdown time

The blowdown time is required to depressurise

the compressor internally when the motor stops.

This prevents starting against excessive internal

pressures. This also sets the start delay after a

power failure. Set times at 5sec intervals for

multi m/c installations.

20s

5s

60s

Fan delay

The time that the digital output to the fan motor

is delayed after stopping the compressor.

2 m

1m

5m

Pump delay

The time that the digital output to the cooling

water motor is delayed after stopping the

compressor.

15s

1s

120s

Run hours

Total amount of compressor running hours

0

0

99900

Half load

Total amount of hours the compressor has been

running on ½ load.

0

0

99900

Full load

Total amount of hours the compressor has been

running on full load.

0

0

99900

Stage 3 cycles

The number of times the 3

rd

stage pressure has

gone below its low pressure level.

0

0

99900

Drain open time

Opening time of the drain valves to release

moisture from the separators.

20s

***

5s

30s

Drain closed

time

The time the drain valves are kept closed before

opening to release the moisture. See manual for

recommended times with various ambient

conditions.

15m

***

3m

45m

Defaults

Reinstalls all the default settings and values to

the original as supplied settings.

Table 9

***

THESE SETTINGS WILL VARY WITH COMPRESSOR TYPE AND OPERATING DUTY.

GUIDELINES ARE GIVEN IN SECTION 2.2.7.1 TABLE 9A.

Summary of Contents for 5280D.1.IAC

Page 3: ...DATE REMARKS DATE REMARKS logsheet5280 d...

Page 9: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 6 1440 doc...

Page 29: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 26 1440 doc...

Page 33: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 30 1440 doc...

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 36 1440 doc...

Page 44: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 38 1440 doc CRANKCASE 1...

Page 46: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 40 1440 doc CRANKCASE 2...

Page 48: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 42 1440 doc CRANKCASE 3...

Page 50: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 44 1440 doc CYLINDER 1st STAGE...

Page 52: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 46 1440 doc SUCTION VALVE COVER...

Page 60: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 54 1440 doc CROSSHEAD 1st STAGE...

Page 62: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 56 1440 doc PISTON 1st STAGE...

Page 64: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 58 1440 doc GLAND 1st STAGE...

Page 66: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 60 1440 doc OIL PUMP...

Page 68: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 62 1440 doc OIL PUMP FILTER...

Page 70: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 64 1440 doc INTERCOOLER...

Page 72: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 66 1440 doc 1st STAGE PIPE WORK...

Page 74: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 68 1440 doc...

Page 76: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......

Page 86: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 70 1440 doc...

Page 94: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 72 1440 doc...

Page 98: ...App 408 Customer PET controller installation guide user s manual Page 2 App 408C 98155 1015...

Page 120: ...CompAir UK Ltd APP 004 ANTI VIBRATION MOUNTS Page 2 app004 doc...

Page 122: ...CompAir UK Ltd PUBLICATION APP070 PRESSURE GAUGES GENERAL Page 2 app070 doc...

Page 128: ...CompAir UK Ltd PUBLICATION APP 138 3 WAY SOLENOID VALVES PS2197 Page 2 app138 doc...

Page 130: ...CompAir UK PUBLICATION APP034 ELECTRIC MOTOR MAINTENANCE GENERAL Page 2 APP034 doc...

Page 133: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 74 1440 doc...