CompAir UK Ltd.

5280D Compressor Publication 98407.1440

Page 10

1440.doc

3. GENERAL

SAFETY

PRECAUTIONS

(Cont.)

•

Before releasing compressed air through a hose

make sure the free end is held securely so that it

cannot whip and cause injury.

•

Avoid injury by using a hoist to lift heavy loads.

Check that all chains, hooks, shackles and slings

are in good condition and are of the correct

capacity. They must be tested and approved

according to local safety regulations.

•

Cables, chains or ropes should never be applied

to lifting eyes. Always use an appropriate shackle

or hook, properly positioned. Arrange lifting

cables so that there are no sharp bends. Use a

spreader bar to avoid side loads on hooks, eyes

and shackles and never leave a heavy load

unattended.

•

When a load is on a hoist stay clear of the danger

area beneath and around it. Keep lifting

acceleration and speed within safe limits.

4. INSTALLATION

PRECAUTIONS

•

Installation work must only be carried out by

competent personnel under a qualified

supervisor.

•

A fused isolator switch must be fitted between the

main power supply and the compressor.

•

Precautions must be taken to ensure that no

injury is caused to passers-by through loose

clothing being sucked into compressor intake.

•

Ensure that the discharge pipe from the

compressor to the users pipework, receiver or

storage is free to expand and that no flammable

material is within the vicinity. If any such material

is close-by take steps to preclude ignition.

•

A manual shut-off valve should be fitted in the

discharge line to allow the compressor to be

isolated. Non return valves cannot be relied upon

for isolating parts from a pressure system. A

safety valve must be installed between any

compressor unit and the isolating valve.

•

A pressure reliving device must be fitted to every

pressure vessel, or equipment containing air or

gas above atmospheric pressure. Never remove

or tamper with safety devices, guards or

insulation fitted. In order to limit the risk of

Legionnaires Disease, CompAir

UK LTD

advise

caution with the use of cooling towers for water

cooling the compressor. Closed circuit or direct

mains cooling is preferred.

•

Pipework or other parts with a surface

temperature above 70°C which may be

accidentally touched in normal operation must be

guarded or insulated. Other high temperature

pipework should be clearly marked and all

pipework should be clearly marked.

5. OPERATIONAL

PRECAUTIONS

•

The compressor must only be operated by

competent personnel under a qualified

supervisor.

•

Do not operate compressor with any removable

inspection cover removed e.g. crankcase

doors,

valve covers etc.

•

Never remove or tamper with safety devices,

guards or insulation materials.

•

The compressor must only be operated at the

supply voltage and frequency for which it is

designed. Always isolate power before

maintenance or servicing.

•

When mains power is ON, lethal voltages are

present in the electrical circuits and extreme

caution is need when essential work is carried out

on the electrical system.

ALWAYS CONSULT A

QUALIFIED

ELECTRICIAN BEFORE ANY

SUCH

ESSENTIAL WORK.

•

Do not open starter compartment to touch

electrical components while voltage is applied

unless it is necessary for measurement, test or

adjustment.

•

Such work should always be carried out by a

qualified. Electrician with appropriate tools and

protection against an electrical hazard.

•

If the unit is equipped with a Remote Control

device, attach warning notices stating

"THIS

UNIT CAN BE STARTED REMOTELY"

in

prominent locations, one on the outside of the

unit, the other inside the control compartment.

•

As a further safeguard, take adequate

precautions that no one is working or checking

the unit before attempting to switch on remotely

controlled equipment. Attach a

"CHECK THAT

ALL PERSONNEL ARE

CLEAR OF UNIT

BEFORE STARTING"

or similar notice.

•

Compressed air and gas piping, together with

cooling water piping and other parts, with surface

temperature greater than 70°C and may be

accidentally touched, should be guarded or

insulated.

Summary of Contents for 5280D.1.IAC

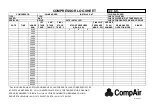

Page 3: ...DATE REMARKS DATE REMARKS logsheet5280 d...

Page 9: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 6 1440 doc...

Page 29: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 26 1440 doc...

Page 33: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 30 1440 doc...

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 36 1440 doc...

Page 44: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 38 1440 doc CRANKCASE 1...

Page 46: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 40 1440 doc CRANKCASE 2...

Page 48: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 42 1440 doc CRANKCASE 3...

Page 50: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 44 1440 doc CYLINDER 1st STAGE...

Page 52: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 46 1440 doc SUCTION VALVE COVER...

Page 60: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 54 1440 doc CROSSHEAD 1st STAGE...

Page 62: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 56 1440 doc PISTON 1st STAGE...

Page 64: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 58 1440 doc GLAND 1st STAGE...

Page 66: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 60 1440 doc OIL PUMP...

Page 68: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 62 1440 doc OIL PUMP FILTER...

Page 70: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 64 1440 doc INTERCOOLER...

Page 72: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 66 1440 doc 1st STAGE PIPE WORK...

Page 74: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 68 1440 doc...

Page 76: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......

Page 86: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 70 1440 doc...

Page 94: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 72 1440 doc...

Page 98: ...App 408 Customer PET controller installation guide user s manual Page 2 App 408C 98155 1015...

Page 120: ...CompAir UK Ltd APP 004 ANTI VIBRATION MOUNTS Page 2 app004 doc...

Page 122: ...CompAir UK Ltd PUBLICATION APP070 PRESSURE GAUGES GENERAL Page 2 app070 doc...

Page 128: ...CompAir UK Ltd PUBLICATION APP 138 3 WAY SOLENOID VALVES PS2197 Page 2 app138 doc...

Page 130: ...CompAir UK PUBLICATION APP034 ELECTRIC MOTOR MAINTENANCE GENERAL Page 2 APP034 doc...

Page 133: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 74 1440 doc...