CompAir UK Ltd.

5280D Compressor Publication 98407.1440

Page 11

1440.doc

5. OPERATION

PRECAUTIONS (Cont.)

•

If there is any indication that the compressor is

overheating it must be shut-down. (A high air or

gas temperature switch is fitted as standard to

guard against operating with excessive

temperature). Beware of burns from hot oil and

water when working on a unit recently shut-down.

•

Do not operate the unit when guards provided for

protection for all rotating and reciprocating parts

have been removed for essential maintenance.

Secure guards following any servicing or repair.

•

Local noise regulations must be observed. Ear

defenders are suggested by Noise at Work

Regulations 1989 when the level is greater than

85 dB A at one meter. Be aware high noise levels

can interfere with communication.

6.

MAINTENANCE & REPAIR

PRECAUTIONS

•

Maintenance repair and modifications must be

carried out by competent persons under qualified

supervisor.

•

The compressor will have a preserving oil applied

to interior surfaces (Oil lubricated models). Oil

free models will have desiccant bags in valve

covers and distance pieces.

•

Handling components such as seals, gaskets and

diaphragms should not present a personnel

hazard. Preservation oils again should not

present a personnel hazard if handled under

normal handling practices.

•

Whilst compressors are asbestos free, treat all

damaged gaskets as asbestos - when the

Asbestos at work regulations apply.

•

Viton 'O' seals under normal operating conditions

are safe.

•

However, should there be a fire within the

compressor or these seals are likely to exceed a

temperature of 300°C the material will

decompose.

•

Degraded Viton gives off Hydrogen Fluoride

fumes and if in contact with the skin an acid

formed causes severe burns.

•

If Viton seals appear charred or gummy

do not

touch with unprotected hands: use neoprene or

PVC gloves.

•

Wash the area with lime water and avoid

breathing any fumes. If contamination of the skin

occurs was with lime water and seek medical

advice.

Pre-Maintenance Operation

•

1. Isolate the compressor from the main electrical

supply. Lock the isolator in the OFF position and

remove fuses.

•

2. Attach a label

" WORK IN PROGRESS - DO

NOT APPLY VOLTAGE"

.

•

3. Close the isolating valve between the

compression unit and user's pipework. Close the

isolating valve in the cooling water inlet pipe.

Attach a label

"WORK IN

PROGRESS - DO NOT

OPEN".

•

4. Check that all pressurised gas trapped in the

system is released to atmosphere or safely to gas

storage. Check that all pressure gauges register

zero.

•

5. Ensure that the cooling water system has been

drained.

•

6. Check that the drain valve on the delivery

manifold is clear and gas pressure has been

released.

•

7. Check that all interstage drains are open to

ensure any gas trapped between stages has

been released.

•

Stand clear of all valve covers when removing the

securing screws.

•

When removing valve covers for valve

replacement, ensure a minimum of two threads

are left engaged on the valve cover securing

screws. Lever the valve cover until the 'O' seal is

disengaged from the port in the cylinder head.

Remove the securing screws and take out valve

cover.

•

Use only lubricating oils and greases

approved by CompAir UK Ltd to avoid

potential hazards especially the risk of

explosion or fire and the possibility of

decomposition or generation of hazardous

gases.

•

Always clean oil spills from the

surrounding floor

before and after maintenance work.

Summary of Contents for 5280D.1.IAC

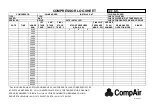

Page 3: ...DATE REMARKS DATE REMARKS logsheet5280 d...

Page 9: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 6 1440 doc...

Page 29: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 26 1440 doc...

Page 33: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 30 1440 doc...

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 36 1440 doc...

Page 44: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 38 1440 doc CRANKCASE 1...

Page 46: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 40 1440 doc CRANKCASE 2...

Page 48: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 42 1440 doc CRANKCASE 3...

Page 50: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 44 1440 doc CYLINDER 1st STAGE...

Page 52: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 46 1440 doc SUCTION VALVE COVER...

Page 60: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 54 1440 doc CROSSHEAD 1st STAGE...

Page 62: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 56 1440 doc PISTON 1st STAGE...

Page 64: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 58 1440 doc GLAND 1st STAGE...

Page 66: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 60 1440 doc OIL PUMP...

Page 68: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 62 1440 doc OIL PUMP FILTER...

Page 70: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 64 1440 doc INTERCOOLER...

Page 72: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 66 1440 doc 1st STAGE PIPE WORK...

Page 74: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 68 1440 doc...

Page 76: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......

Page 86: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 70 1440 doc...

Page 94: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 72 1440 doc...

Page 98: ...App 408 Customer PET controller installation guide user s manual Page 2 App 408C 98155 1015...

Page 120: ...CompAir UK Ltd APP 004 ANTI VIBRATION MOUNTS Page 2 app004 doc...

Page 122: ...CompAir UK Ltd PUBLICATION APP070 PRESSURE GAUGES GENERAL Page 2 app070 doc...

Page 128: ...CompAir UK Ltd PUBLICATION APP 138 3 WAY SOLENOID VALVES PS2197 Page 2 app138 doc...

Page 130: ...CompAir UK PUBLICATION APP034 ELECTRIC MOTOR MAINTENANCE GENERAL Page 2 APP034 doc...

Page 133: ...CompAir UK Ltd 5280D Compressor Publication 98407 1440 Page 74 1440 doc...