5. Extended functions

10

5

Exten de d f un cti on s

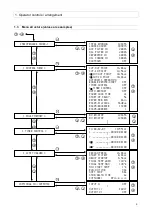

5.1 [ CONTROL MENU ] sub-menu

The most important parameters of the

[

CONTROL

MENU

]

menu have already been explained

in section 2 Default settings. This section simply

contains an overview and explanation of additional

(extended) functions.

5.1.1 Operating modes

Go to the

[

CONTROL

MENU

]

sub-menu and use the

key to go to the

AUTOMATIC

OPERATION

menu item. If

you press the

key, the

AUTOMATIC

OPERATION

value starts to flash. You can use the

key to now

switch to

CONTINUOUS

OPERATION

. Confirm a set

value by pressing the

key.

You can choose from two operating modes:

AUTOMATIC OPERATION

AUTOMATIC

OPERATION

is the most economical of

your compressor's operating modes. If there is no need

for compressed air in your system, the compressor is

shut down after the

RUN-ON

TIME

. The control system

automatically recognises when compressed air is

needed again. The unit then starts up straight away.

CONTINUOUS OPERATION

CONTINUOUS

OPERATION

is only needed for some

special applications. When in this operating mode, the

motor is not shut down if there is no longer any need for

pressure. The compressor stage now runs continually

in off-mode when there is no need for pressure.

5.1.2 Second pressure range (

p

2

)

The range between the maximum and minimum

network pressure is called the pressure range. The

second pressure range function allows you to use

another pressure range in addition to the pressure

range already set (see section 2.2). This could be used

to for example implement night-time lowering.

You will find the settings for the second pressure range

function in the

[

CONTROL

MENU

]

sub-menu. The

relevant menu items there are:

p

2

CUT-OUT

POINT

10.5bar

p

2

CUT-IN

POINT

10.0bar

p

2

TIMER

CONTROL

OFF

You can use

p

2

CUT-OUT

POINT

and

p

2

CUT-

IN

POINT

to set the network pressure switching points.

Use the

p

2

TIMER

CONTROL On

menu item to activate

the timer for the second pressure range.

You can activate / deactivate the second pressure

range using an external potential-free contact (see

section 5.5).

Section 5.3.2 contains a description of how to set the

timer for the second pressure range.

Note

The values shown are examples only. The values used

in your unit may be different.

5.1.3 Dryer pre-run

If you are using an external dryer, you can provide the

compressor with a specified pre-run time. The

compressor is then only started after this pre-run time.

To set the pre-run time, please go to the

[

CONTROL

MENU

]

sub-menu. From there use the

key to go to the

DRYER

PRE-RUN 0min

menu item.

Once you have pressed the

key, the

0min

value

starts to flash. You can now use the

or

keys to

set the pre-run time you want. Then confirm your entry

using the

key.

5.1.4 RS 485 communication

You can perform the settings for RS 485

communication in the

[

CONTROL

MENU

]

sub-menu.

The

RS485-ProTOCOL

ModBus

RS485-BAUDRATE

19200

RS485-ADDRESS

1

menu items are of relevance.

The DELCOS

Pro

has a serial RS485 interface. This

interface can be used with the ModBus RTU protocol.

ModBus interfaces and drivers are available from many

of the well-known manufacturers of programmable logic

controllers (PLC).

You can set the baud rate you want in the

RS485-

BAUDRATE

menu item.

You can set the participant number you want in the

RS485-ADDRESS

menu item.

Note

The values shown are examples only. The values used

in your unit may be different.