5. Extended functions

16

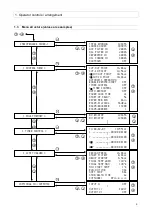

5.5.2 Outputs

Attention

The maximum connected loads for the

programmable outputs (relay contacts) are 1A /

240V.

The DELCOS

Pro

has two programmable outputs.

Output 1 is a relay with changeover contact and output

2 is a relay with NO contact. You can assign (program)

various functions to the outputs.

The outputs are programmed in the

[OPTIONAL

IN-

/OUTPUTS]

sub-menu. Please go to the

[OPTIONAL

IN-/OUTPUTS]

sub-menu. Then go to

the

OUTPUT

1: FAULT

menu item

If you press the key, the function starts to flash. By

pressing the

or

key, you can now change the

function. Once you have set the function you want, this

has to be confirmed using the key. The output is now

programmed.

You access the other programmable output by pressing

the

key.

When supplied, output 1 is programmed with the

'

FAULT

' function. Output 2 is not programmed upon

delivery. Each of the two outputs an be programmed

with any of the functions listed below. You will also find

an overview of the inputs and associated functions in

the machine's circuit diagram.

Explanation of functions:

FREE

Output is not programmed.

OPERATING

The output (relay) is activated when the compressor's

motor is switched on or when the compressor is ready.

ON-LOAD

The output (relay) is activated when the compressor is

in on-load.

OFF-LOAD

The output (relay) is activated when the compressor is

in off-load.

FAULT

The output (relay) is activated when there are no faults

on the compressor.

WARNING

The output (relay) is activated when there are no

warnings on the compressor.

MAINT.

ELAPSED

The output (relay) is activated when there are no

maintenance messages on the compressor.

WARNING/MAINT.

The output (relay) is activated when there are no

warnings and no maintenance messages on the

compressor.

WARN/MA/FAULT

The output (relay) is activated when there are no

warnings, no maintenance messages and no faults on

the compressor.

REM.STARTABLE

The output (relay) is activated when the compressor is

ready for the remote start.

RUNNING

The output (relay) is activated when the compressor's

motor is running (is switched on).

5.6 Locking / unlocking code

Settings (sub-menus) can be locked using a code to

prevent unauthorised programming.

Limit values cannot be changed by the operator.

Locking

If the code is to be locked, this is done using the

key.

Please press this key for 5 seconds. The following

message then appears on the display:

CODE:

UNLOCK

(for 1 second)

CODE

INPUT 0000

(

0000

value flashes)

If the code: 3031 is entered, the following message

appears:

CODE:

LOCK

(for 1 second)

The sub-menus are now locked and cannot be

changed.

If the wrong code is entered, the following message

appears:

CODE:

UNLOCK

(for 1 second)

The display then automatically jumps back to where it

started from.

Unlocking

If the code is to be unlocked again, this either done by:

*

pressing (for 5 seconds) the

key when not in the

menu or

*

pressing (for 5 seconds) the

key when attempting

to change a protected value in a sub-menu.

The code prompt then appears:

CODE:

LOCK

(for 1 second)

CODE

INPUT 0000

(

0000

value flashes)