5. Extended functions

19

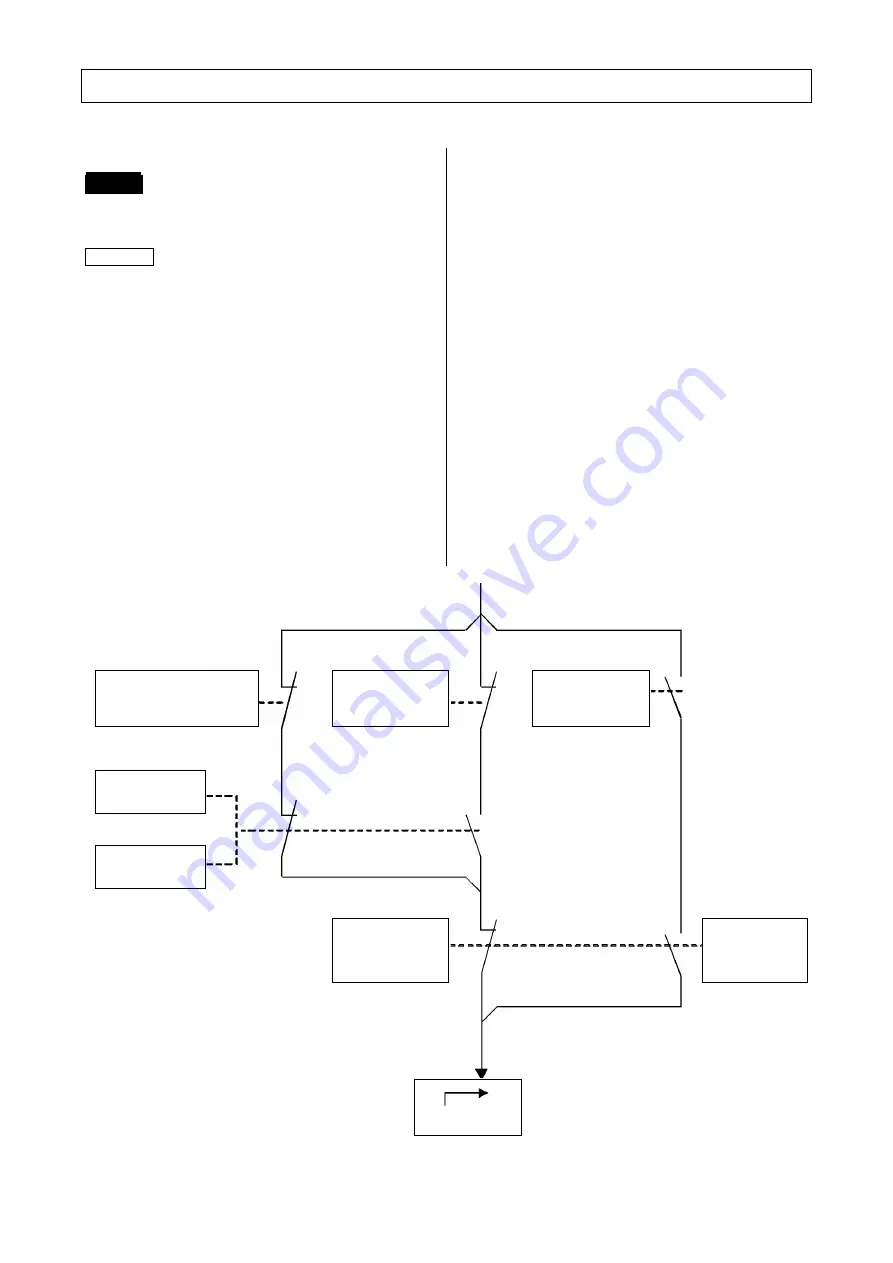

5.8.2 On-load/off-load remote control

Danger

In this operating mode, the compressor may start

automatically at any time.

Attention

Only potential-free contacts may be connected to

the terminal strip. External voltages will destroy the

DELCOS

Pro

.

The potential-free contacts must not be more than

20 metres away from the terminal strip.

If necessary coupling relays must be fitted in the

control cabinet.

The DELCOS

Pro

control system allows the operator to

switch the compressor into on-load or off-load from a

remote point through the connection of two potential-

free contacts. This function is needed when using an

external control for example.

To do this, go to the

[OPTIONAL

IN-/OUTPUTS]

menu where you must program one input with the

ENAB.REM.LOAD

function and another with the

REMOTE

LOAD

function. The unit can now be switched to

on-load or off-load using these two inputs.

You will find a circuit diagram in Fig. 6. In our

explanation, we have assigned the inputs as follows:

INPUT

1:ENAB.REM.LOAD

INPUT

2:REMOTE

LOAD

You can of course program the inputs any way you

choose.

If input 1 is activated, the unit can only be switched into

on-load or off-load by remote control. Both pressure

ranges and time control mode are interrupted

(decoupled). If input 2 is now activated, the machine is

in on-load. If input 2 is not activated, the machine is in

off-load.

If the supply pressure exceeds the preset operating

pressure of 0.5 bar, the

WARNING LINE

PRESS

indication appears on the display. Remote control is

deactivated at the same time. The unit now runs again

using one of the preset pressure ranges until the

WARNING LINE

PRESS

is acknowledged.

CUT-OUT POINT

CUT-IN POINT

p2 CUT-OUT

p2 CUT-IN

INPUT X:

REMOTE LOAD

p2 TIMER CONTROL

INPUT X:

2nd PR. RANGE

INPUT X:

ENAB.REM.LOAD

WARNING

LINE PRESS

ON-LOAD

Fig. 6 On-load/off-load remote control circuit diagram