2. Default settings

7

2

Defa ult set tin gs

2.1 Selecting language

You can change the language by pressing the +

or +

keys. Press these keys at the same time until

the right language appears.

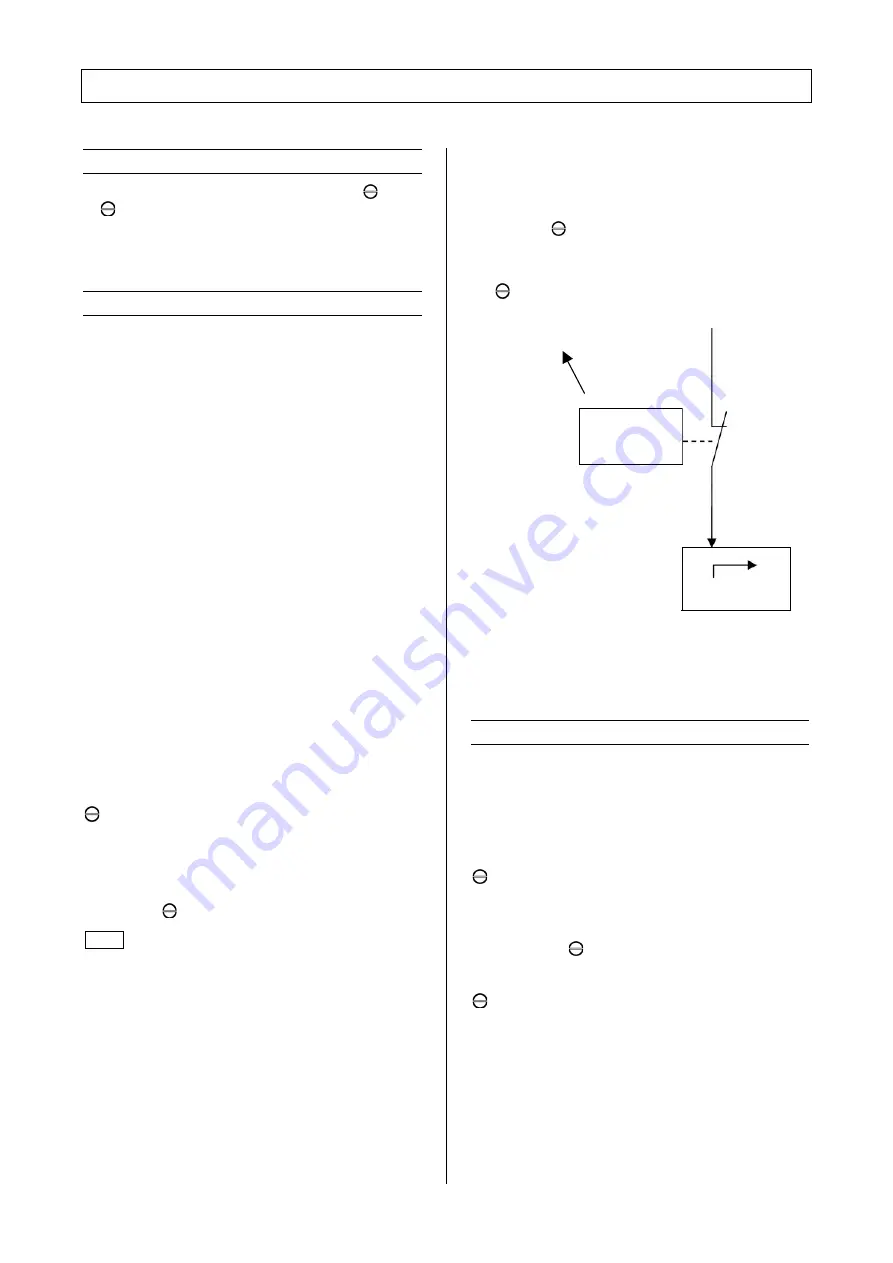

2.2 Setting network pressure

The compressor is controlled using an electronic

pressure switch. In the

[

CONTROL

MENU

]

menu you

have to set the minimum network pressure switching

point (

CUT-IN

POINT

) and the maximum network

pressure switching point (

CUT-OUT

POINT

).

When the maximum network pressure switching point is

reached, the machine switches to off-load.

The minimum network pressure switching point then

specifies when the machine is switched back into on-

load.

Example:

CUT-OUT

POINT 10.0bar

CUT-IN

POINT

9.8bar

When the network pressure reaches 10.0 bar, the

machine switches to off-load.

If the network pressure then falls to 9.8 bar, the

machine is switched back into on-load.

Max. network pressure:

The network pressure is set in the

[

CONTROL

MENU

]

sub-menu. The

+

keys -

have to be pressed at the same time to do this. You are

then taken to the main menu. Use

to switch to the

[

CONTROL

MENU

]

sub-menu. Then please press the

key.

The

CUT-OUT

POINT

menu item now appears on the

display. Again pressing the

–

key causes the value to

flash. You can now correct (increase or decrease) this

value using

or

. Then confirm the value set by

pressing the key.

Note

The control system checks whether the value set can

be used. The maximum network pressure

CUT-

OUT

POINT

must be at least 0.2 more than the

minimum network pressure

CUT-IN

POINT.

You may

therefore have to first set the minimum network

pressure point. To prevent your compressor suffering

from excess wear, the difference between the

CUT-

OUT

POINT

and

CUT-IN

POINT

should not be too

small.

Min. network pressure:

In the

[

CONTROL

MENU

]

sub-menu please use

to go to the

CUT-IN

POINT

menu item.

Pressing the key causes the value to flash.

You can now correct (increase or decrease) this value

using

or

. Then confirm the value set by pressing

the key.

CUT-OUT POINT

CUT-IN POINT

ON-LOAD

Pressure switch

Fig. 1 Block diagram

2.3 Setting time/date (timer)

The DELCOS

Pro

accumulator can bridge a loss of

power lasting between around two to three weeks. If

power is lost for longer periods, the timer's time and

date are lost and have to be entered anew.

Press the

+

keys at the same time. Use

to go

to the

[

TIMER

CONTROL

]

sub-menu and press the

key. The date and time are displayed there in the

following format:

TU 30.10.07 12:10:34

If you press the key, the left-hand value (day of the

week) starts to flash. You can now use the

or

keys to set this. Then confirm the value by pressing the

key.

All values can now be set in succession using this

procedure. When the last value (seconds) has been

set, the timer is fully set and you can exit the menu by

twice pressing the

+

keys at the same time.