22

CompAir

5.1

Transport

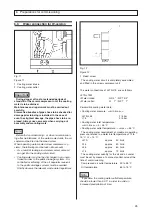

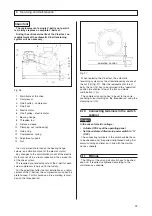

Fig. 6

Danger

.

The screw compressor unit must be lifted using a

suitable fork lift truck, which complies with the local

safety regulations.

Before lifting, all loose or slewable parts of the ma-

chine have to be firmly secured.

It is strictly prohibited to work or stand in the dan-

ger zone of a lifted load.

The proper lifting of the load (according to the ope-

rating instructions of the load suspension device)

has to be ensured.

Weights

(with electric motor IP 23)

The values listed below are approximate values, they

refer to a screw compressor unit including oil fill :

Version:

L37S

approx. 1120

kg

L45

approx. 1165

kg

L55

approx. 1170

kg

L75

approx. 1280

kg

5. Transport and installation

Important

Never lift or lash the compressor via its enclosure.

The screw compressor is lifted with the help of a

fork lift truck (fig. 6). The separation of the forks and

their length must be taken into account for trans-

portation.

Only use the identified lifting points. Do not slide

the unit when it is standing on the floor.

Weights

(with electric motor IP 55)

The values listed below are approximate values, they

refer to a screw compressor unit including oil fill :

Version:

L34S

approx. 1165

kg

L45

approx. 1260

kg

L55

approx. 1370

kg

L75

approx. 1460

kg

A

A

A

B

B

B

A = 0,9 m

B = 0,9 m

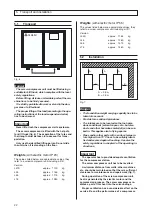

Fig. 7

5.2

Installation

Danger

.

• The foundation weight carrying capacity has to be

taken into account.

• Provide for a solid and plane base.

• The intakes are to be located so that no hazar-

dous constituent (solvent vapour, etc., but also

dusts and other hazardous material) can be suk-

ked in. This applies also to flying sparks.

• Pipes and/or other parts with a surface tempera-

ture higher than 70 °C have to be suitably identi-

fied and secured against touching. See also the

safety regulations in chapter 3 of the operating in-

structions.

Important

The operator has to provide adequate ventilation

for the compressor station.

The screw compressor unit has to be levelled.

A minimum distance from walls, other machines,

etc. should be maintained so that there is sufficient

clearance for maintenance and repair work (fig. 7).

During operation of the screw compressor unit,

heat is generated by the electric motor and the

compression process. The screw compressor ra-

diates a part of this heat into the surroundings.

Proper ventilation has a considerable effect on the

service life and the performance of a compressor.