Appendix

B

Loading Flash Memory

216

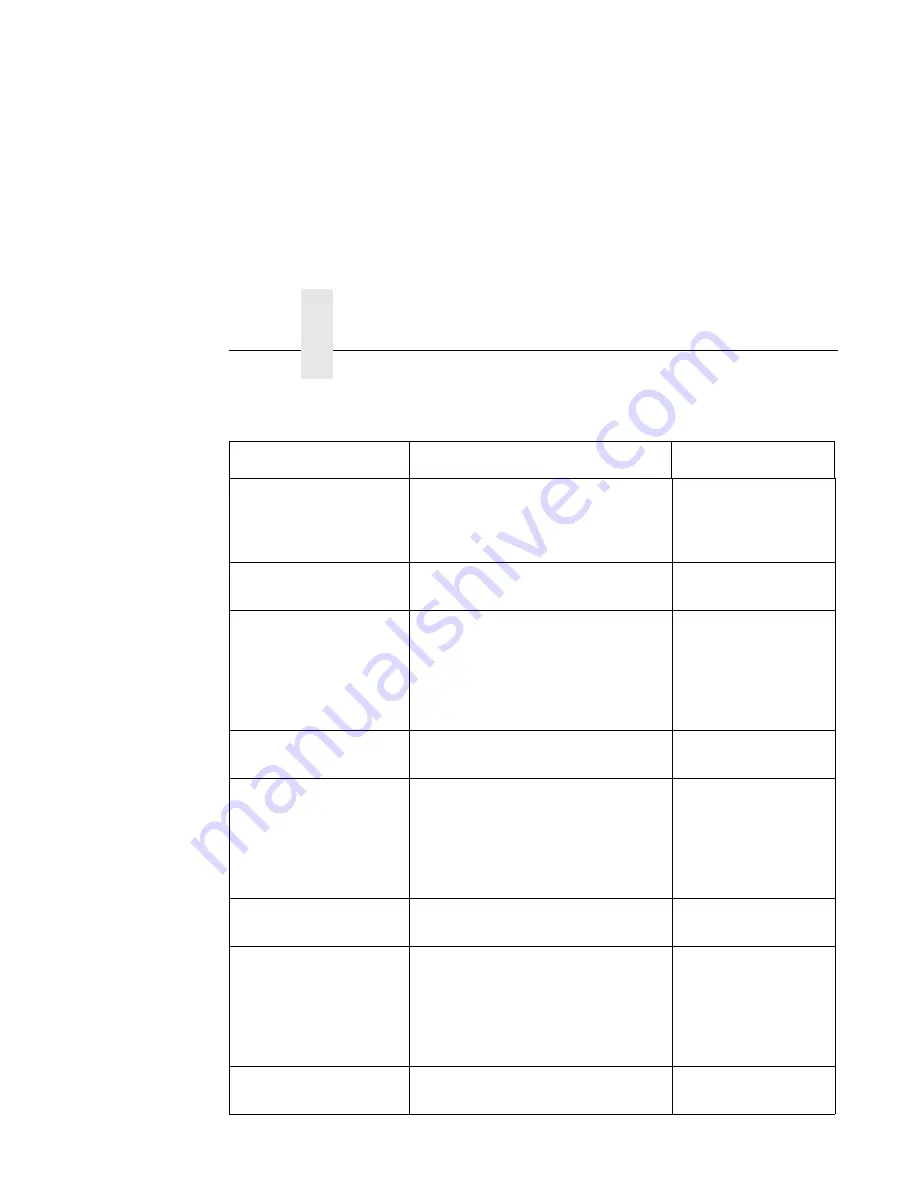

Table 16. Flash Memory Message Guide

Message

Explanation

Required Action

CLEARING PROGRAM

FROM FLASH

The program successfully loaded

into printer RAM and the checksum

matched. The old program is now

being deleted from flash memory.

None

DIAGNOSTIC

PASSED

The printer passed its memory and

hardware initialization tests.

None

ERROR: DC

PROGRAM

NOT VALID

Printer cannot find the data controller

program or the validation checksum

is corrupt.

Download the

program again. If the

message occurs

again, call your

service

representative.

ERROR: DRAM AT

ADDRESS XXXXXXXX

The printer found a defective

memory location.

Call your service

representative.

ERROR: EC

PROGRAM

NOT VALID

Printer cannot find the engine

controller program or the validation

checksum is corrupt.

Download the

program again. If the

message occurs

again, call your

service

representative.

ERROR: EC STOPPED

AT STATE XXXX

Hardware fault in the engine

controller.

Call your service

representative.

ERROR: FLASH

DID NOT PROGRAM

The printer encountered an error

trying to program flash memory.

Download the

program again. If the

message occurs

again, call your

service

representative.

ERROR: NO DRAM

DETECTED

The printer could not find any

DRAM.

Call your service

representative.

Summary of Contents for PrintNet 5525B

Page 1: ...5525B 31 32 Line Matrix Printer User s Manual ...

Page 3: ...5525B 31 32 Line Matrix Printer User s Manual P N 422721 001 ...

Page 10: ...Table of Contents 10 ...

Page 194: ...Chapter 5 Configuring the Internal Ethernet Adapter for Windows 194 ...

Page 199: ...Printing a Hex Dump 199 Figure 15 Hex Dump Sample ...

Page 220: ...Appendix C 220 ...

Page 236: ...Index 236 ...

Page 237: ......

Page 238: ...170115 001A 5525B 31 32 Line Matrix Printer Compaq Computer Corporation P N 422721 001 ...