PM1323

St ar ti ng

Wa tt s

R u nni ng

W at ts .

R ating

Far m Equipment

1650

3400

4400

2900

650

1000

1400

1100

2800

2000

6000

8000

10700

Mixers

High Pressure .8 Gal/Min

3300

1000

950

6-1/2"

7-1/4"

8-1/4"

500

900

1400

9"

10"

4500

6300

1500

1800

Band Saw

14"

2500

1100

6"

8"

10"

1720

3900

5200

720

1400

1600

1/2 HP

1 HP

1-1/2 HP

2 HP

3000

6000

8200

10500

1000

1500

2200

2800

Electric Chain Saw

1-1/2 HP 12"

2 HP 14"

1100

1100

1100

1100

Standard

9" trabajo

pesado 12"

350

500

350

500

1/3 HP

18"

2100

400

700

400

125

313

1000

1400

1250

100

250

1000

400 GHP

Centrifugal Pum p

900 GHP

3/4 HP, 16"

1 HP, 20"

1/2 HP

3/4 HP

1 HP

1/4 HP

1.7 HP

2-1/2 HP

600

200

500

900

4500

6100

1400

1600

950

1400

1600

3150

4500

6100

700

900

1300

1900

900

1300

1750

1500

2100

1750 T ipica

1500

2100

Microwaves

6000

2800

6000

2000

100

300

100

300

50-200

3100

800

2150

2100

750

1000

2100

3200

800

1050

2100

2850

700

1450

1200

1200

300-1200

300-1200

1050

1650

1050

1645

As Indicated on Bulb

800

1100

1450

650

400

550

725

3700

5800

8750

11500

13800

1500

2500

3800

5000

6000

800

1250

1600

2100

3225

300

500

600

700

875

Automatic W asher

1150

2500

7550

700

5750

50-200

720

975

1400

1600

2200

2850

3900

6800

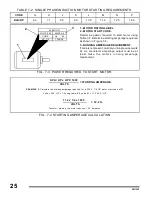

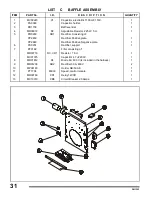

TABLE 7-1 APPROXIMATE POW ER REQUIREMENTS FOR TIPICAL EQUIPMENT*

In dust r ia ls M oto r s

R ating

St ar ti ng

Wa tt s

Split Phase

1/8 HP

1/6 HP

1/4 HP

1/3 HP

1/2 HP

800

1225

1600

2100

3175

300

500

600

700

875

R u nni ng

W at ts .

Capacitor Start-

Induction Run.

1/3 HP

1/2 HP

3/4 HP

1 HP

1-1/2 HP

2 HP

3 HP

5 HP

2020

3075

4500

6100

8200

10550

15900

23300

720

975

1400

1600

2200

2850

3900

6800

Capacitor Start-

Induction Run.

1-1/2 HP

5 HP

7-1/2 HP

10 HP

8100

23300

35000

46700

2000

6000

8000

10700

Fan Duty.

1/8 HP

1/6 HP

1/4 HP

1/3 HP

1/2 HP

1000

1400

1850

2400

3500

400

550

650

800

1100

C on tr ac to r

R ating

St ar ti ng

Wa tt s

R u nni ng

W at ts .

Hand Drill

1/4"

3/8"

1/2"

350

400

600

350

400

600

Circular Saw

500

900

1400

High Pressure W asher

Floor Polisher

Subm ergible Pum p

Flood Lights

Electric T rim mer

Air Com pressor

Bench Grinder

Table Saw

Electric Cultivator

55 Gal Drum Mixer

W et & Dry Vac

Mercurio

Sodio

Vapor

Grain Cleaner

Portable Conveyor

Grain Elevator

Milk Cooler

Milker (Vacuum Pump)

FARM DUTY MOT ORS

std (e.g. Conveyors,

Feed Augers, Air

Com pressors)

High T orque

W ashers 2 Gal/Min

550 PSI

700 PSI

500 PSI

3150

4500

6100

1/2 HP

1/2 HP

5 HP

7-1/2 HP

10 HP

8100

23300

35000

46000

1/3 HP

1/2 HP

3/4 HP

1 HP

1-1/2 HP

2 HP

3 HP

5 HP

1720

2575

4500

6100

8200

10550

15900

23300

2 HP

10500

3/4 HP

1/2 HP

1/4 HP

1000

1000

1400

1600

R u nni ng

W at ts .

St ar ti ng

Wa tt s

R ating

R e si de nt ia l

Coffe Maker

TV

Radio

Froster

Shallow W ell Pum p

Sum p Pum p

Dishwasher

Clothes Dryer

Furnance Blower

Air Aconditioned Central

Automatic Door Garage

Electric Blanket

Dehum idifier

Vacuum Cleaner

Lights

Toaster

Hair Dryer

Ir on

2 Slice

4 Slice

Standard

Delux

800

1100

Portable

400

1/4 HP

1/3 HP

1650

2125

10,000 BT U

20,000 BT U

24,000 BT U

32,000 BT U

40,000 BT U

1/8 HP

1/6 HP

1/4 HP

1/3 HP

1/2 HP

3450

Gas

Electric

Cool Dry

Hot Dry

1/3 HP

1/2 HP

1/3 HP

1/2 HP

B & W

Color

O ve n

625 W

6" Elem ents

8" Elem ents

Stock T ank De-Icer.

24