3

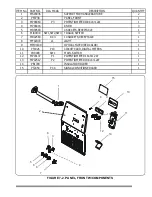

3-3 INSTALLING WELDING GUN (WELDING GUN NOT INCLUDED)

1 Drive Assembly

2 Gun Securing Knob

3 Gun End

Loosen securing knob. Insert gun

end through opening until it bottoms

against drive assembly. Tighten

knob.

4 Gun Trigger Plug

Insert plug into receptacle, and

tighten threaded collar.

Close door.

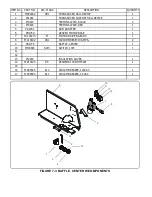

Figure 3-3 Work clamp.

3-2 INSTALLING WORK CLAMP.

9.5, 11.1 mm(3/8, 7/16")

1.- Work Cable from Unit.

2.- Contact Piece.

3.- Screw.

4.- Work Clamp.

5.- Washer.

Tools Needed

3

1

5

2

4

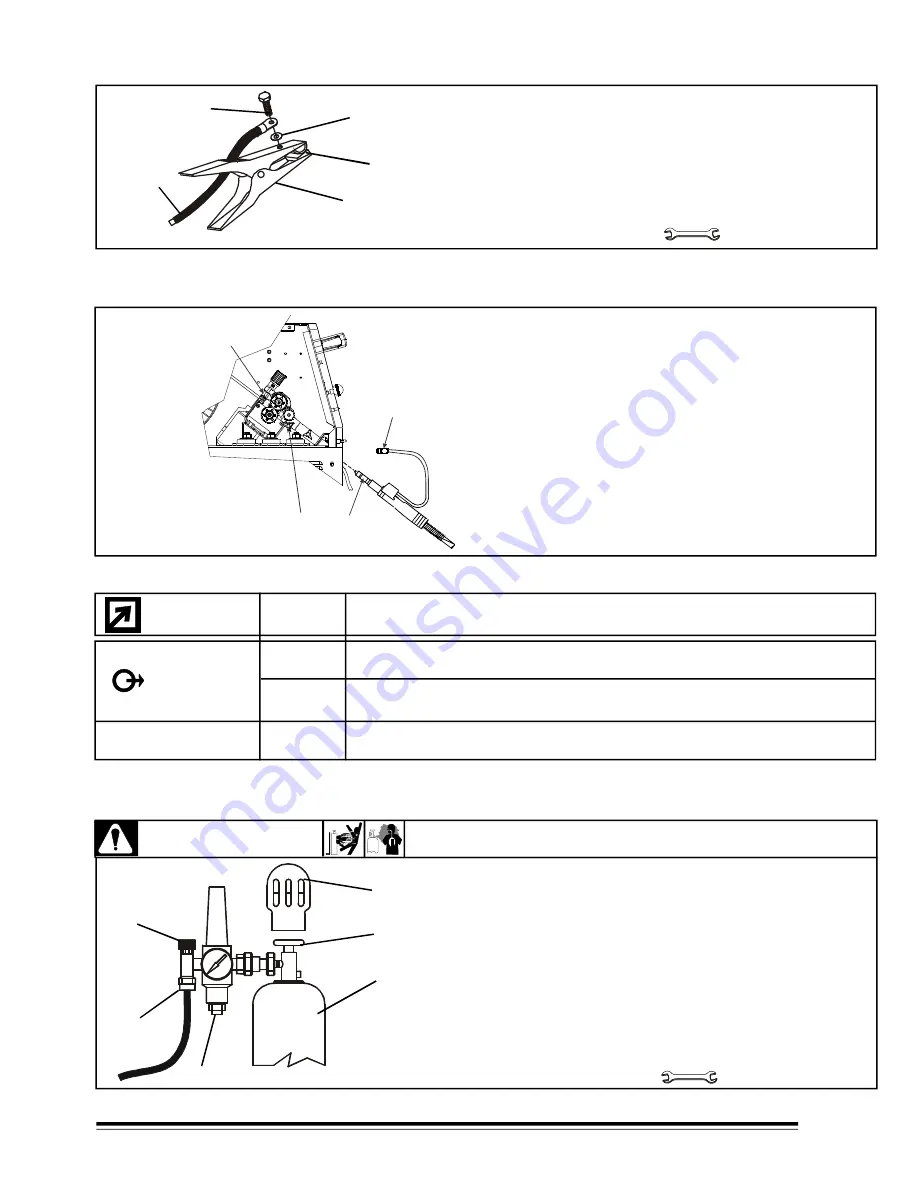

Figure 4-4 Shielded gas connection.

WARNING

SEE SAFETY SIGNALS AT THE BEGINING THIS MANUAL

3-5. SHIELDED GAS CONNECTIONS.

1

2

3

4

5

6

Be sure gas cylinder is held to running gear, wall, or other stationary support

so cylinder can not fall and break off valve.

1.- CAP.

2.- CYLINDER VALVE.

Remove cap, stand to side of valve, and open valve slightly. Gas flow blows

dust and dirt from valve. Close valve.

3.- CYLINDER.

4.- REGULATOR /FLOWMETER.

5.- GAS HOSE CONNECTION.

6.- FLOW ADJUST.

Typical flow rate is 20 cfh ( Cubic Feet per Hour).

28.5, 15.8mm (1-1/8",5/8")

Tools needed:

OUTPUT

(CONTACTOR)

INFORMATION

Socket

REMOTE-14

A

B

I

J

G

K

24 V a.c. Protected by CB2 (10 Amperes).

Contact closure to "A" completes 24 V a.c. contactor control circuit.

120 V a.c. Protected by CB1(10 Amperes).

Contact closure to "I" completes 120 V a.c. contactor control circuit.

Circuit common for 24 and 120 V a.c. circuits.

Chassis common.

NOTE: Remaining sockets are not used

3-4. REMOTE-14 RECEPTACLE INFORMATION.

G N D

1

2

4

3