OUTPUT

(CONTACTOR)

INFORMATION

Socket

REMOTE-14

A

B

I

J

G

K

C

E

D

F

H

24 V a.c. Protected by CB2 (10 Amperes).

Contact closure to "A" completes 24 V a.c. contactor control circuit.

120 V a.c. Protected by CB1(10 Amperes).

Contact closure to "I" completes 120 V a.c. contactor control circuit.

Circuit common for 24 and 120 V a.c. circuits.

Chassis common.

Command reference 10 V d.c.

0 to +10 V d.c. input command signal from remote control.

Remote control circuit common.

Current feedback 0-10 V d.c. 1 Volt per100 weld output Amperes.

Voltage feedback 0-10 V d.c. 1 Volt per 10 weld output Volts

NOTE: Remaining sockets are not used

TABLE 3-2. REMOTE-14 RECEPTACLE INFORMATION.

Figure 3-6 Shielded gas connection.

WARNING

SEE SAFETY SIGNALS AT THE BEGINING THIS MANUAL

6

3-6 SHIELDED GAS CONNECTIONS.

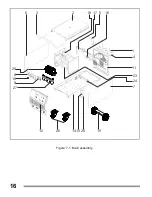

Figure 3-7. Remote-14 and Remote ON-OFF

3-7 REMOTE 14 AND REMOTE ON-OFF RECEPTACLES

1- Remote-14 receptacle RC8 (See table 3-2)

2- Keyway

3- Plug connector 14

4- Collar

5- Remote ON-OFF receptacle (See table 3-3)

To connect this receptacle, align keyway, insert plug and

tighten threated collar.

Turn off power before connecting remote 14 or

remote ON-OFF receptacles

1

2

3

4

5

6

G N D

REMOTE OUTPUT

CONTROL

A / V

INFORMATION

SOCKETS

REMOTE ON-OFF

TABLE 3-3. REMOTE ON-OFF RECEPTACLE INFORMATION.

24V a.c. with 'POW ER'' switch in ''OFF'' position.

Contact closure to "2" completes 24 V a.c. remote power circuit.

ON-OFF

RMT

2

3

Be sure gas cylinder is held to running gear, wall, or other stationary support

so cylinder can not fall and break off valve.

1.- CAP.

2.- CYLINDER VALVE.

Remove cap, stand to side of valve, and open valve slightly. Gas flow blows

dust and dirt from valve. Close valve.

3.- CYLINDER.

4.- REGULATOR /FLOWMETER.

5.- GAS HOSE CONNECTION.

6.- FLOW ADJUST.

Typical flow rate is 20 cfh ( Cubic Feet per Hour).

28.5, 15.8mm (1-1/8",5/8")

Tools needed:

NOTE: Remaining sockets are not used

1

3

4

2

3

4

2

1

5