7

3-8 WELD OUTPUT TERMINALS

1- Access door.

2- Positive Terminal (+), High Inductance.

Use this terminal for MIG STAINLESS STEEL WELDING.

3- Positive Terminal (+), Low Inductance.

Use this terminal for most wire feeding GMAW process (FCAW and SAW ).

However, since usage and application vary.

4- Negative Terminal (-).

Common for welding circuit.

Welding polarity.

CDEP

welding in d.c. whith positive electrode (Microwire in Feeder).

CDEN

welding in d.c. with negative electrode (Microwire in Feeder).

Turn off power before connecting to weld output terminals.

Close access door before weld process begining.

Figure 3-8. Weld Output Terminals.

19 mm (3/4")

Tabla 3-3. Cable size and recommended fuse.

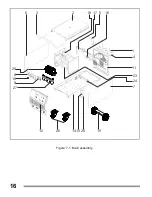

Figure 3-9. Input power connections.

3-9 INPUT POWER CONNECTIONS.

3

2

4

1

Tools Needed:

ELECTRICK SHOCK can kill.

WARNING

ELECTRICK SHOCK can kill.

WARNING

Input voltage:

Rated input current:

Fuse or circuit breaker recommended:

AWG Power cable size :

AWG Ground cable size:

230V ~

52 A.

75 A.

6

8

460V ~

26 A.

50 A.

10

10

575V ~

21 A.

40 A.

10

10

Jumper links allows operation to

diferent input voltages.

Open rear door and move jumper

links to match input voltage as shown label

to adecuate voltage.

1- CONNECTION DIAGRAM.

2- PRIMARY PANEL.

3- POWER SWITCH

.Connect the input

to the switch, using cable size and fuse

capacity according nameplate.

1

2

3

Tools needed

9.5mm (3/8") 11.1mm (7/16")

2 0 VOLTS

3

46 0 VOLTS

57 5 VOLTS

L 1

L 1

L1

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

L2

L 2

L2

L 3

L 3

L3

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6