11

SECTION - 5

MAINTENANCE &TROUBLESHOOTING

5-1 ROUTINE MAINTENANCE

WARNING

SEE SAFETY SIGNAL AT THE BEGINING THIS M ANUAL

5-2 OVERHEATING.

START

WELDING

PROCESS

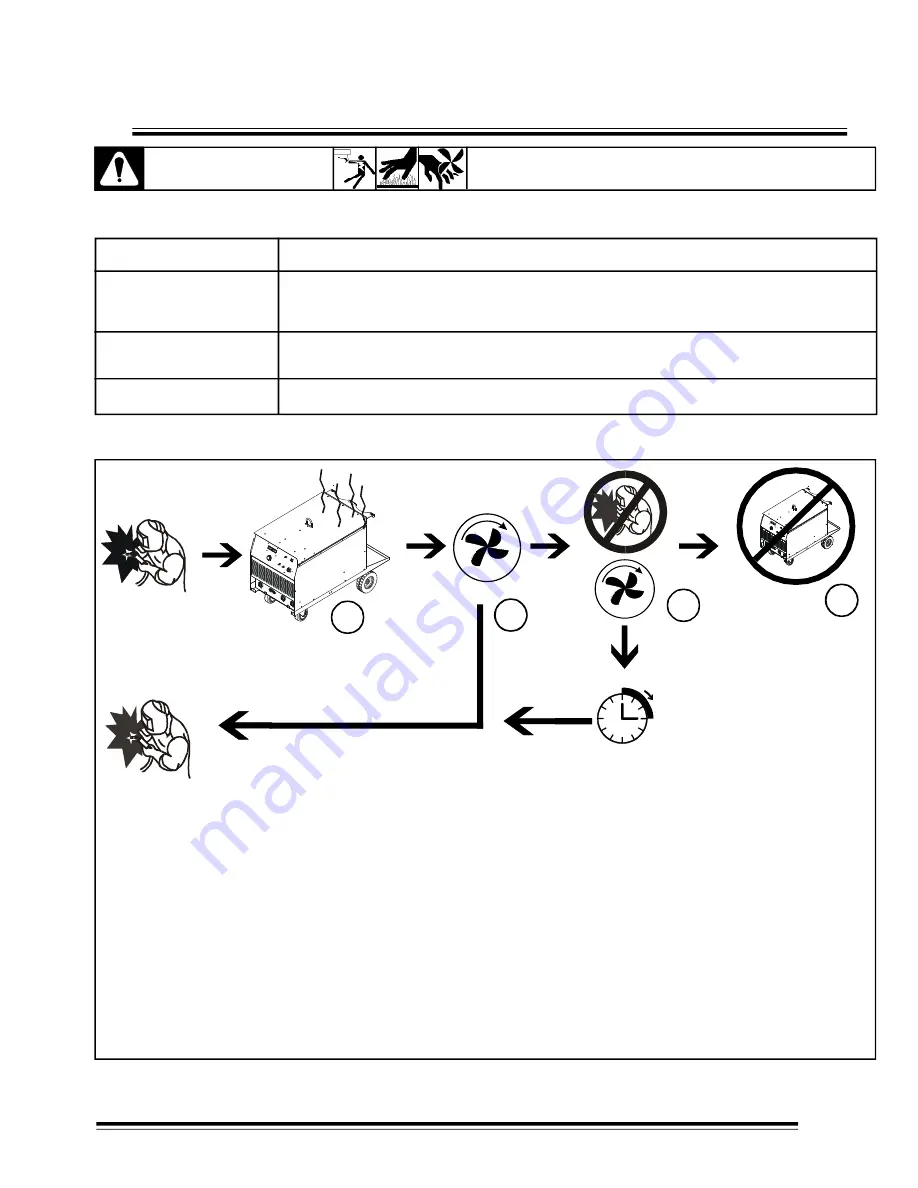

Figure 5-1 Overheat protection.

1

- This unit is designed to initially operate with cooling system.

2

- While unit works, the cooling system maintains a safe temperature so as not to damage internal components

3

- If the cooling system was not enough and the temperature rises to unsafe values, the unit interrupt output and

deploys in the voltmeter and ammeter the message ''ESP ErE'', the cooling system will continue to operate; when the

machine has a temperature to operate safely restart output and the message ''ESP ErE'' disappears.

4

- On the one overheating or failure in the cooling system, the machine will shut down and internally is disconnected from

the line alimenteción..

CONTINUE

WELDING

PROCESS

1

2

3

4

TIME

Above normal equipment use: Check all labels ( see 6 month entry ), repair any damaged

insulation or replace holder or work cable, clean internal parts ( see 6 month entry ), clean and

tighten connections at holder cable and work clamp.

Every month

Every 3 months

Every 6 months

MAINTENANCE

Replace Unreadable Labels, Tape Or Replace Cracket Cables, Clean And Tighten W eld

Terminals, Replace Cracket Parts.

Blow Out Or Vacuum inside,During Heavy Service Clean Monthly.