15

PC0145

PC0990

PM0347

PS0881

PS1027

PT3620

PT3621

PT1794

PT1826

PA0827

MA01108

MM04206

MR01495

MR01520

MR06632

PS1611

PT2654

PA0829

MB04284

MC10192

MI00110

MM04109

MP03137

MP08417

MR00521

MR09784

MI01196

PP3157

PP4578

PT0923

PT0924

PT1875

PS1761

PA1216

MC10687

MS03942

PB1449

PE0649

PR1044

PS0878

PS1128

PT1185

PT3611

PT3615

MF02316

PP3784

MR09754

PB1967

2

1

1

1

1

1

1

1

2

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

2

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

2

1

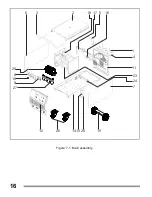

SECTION - 7 PARTS LIST

7-1 MAIN ASSEMBLY

Item

No.

1

2

3

4

5

6

7

8

9

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

Part No.

D e s c r i p t i o n

Quantity

PC1

FM

R1

R3, R4

CB1, CB2

S3

R5

RC2

CR1

S1, S2

W1

HD1

Z1

T1

F1

I.D.

Safety chain

Cover, top

Handlebars

Support for cylinder

Sopport for MIG gun.

Panel, left side

Panel, right side

Control PCB

Digital meter PCB

Panel, rear ASSEMBLY

Blade, 16" VA-407

Motor power 1/6 PSC481646-0883

Resistor ww 20 ohm 10% 300W

Support, rubber No.4

Resistor ww 200 ohm 5% 25W

Fan,motor support

Panel, rear

Panel, front ASSEMBLY

Bushing

Circuit breaker 10 amps.

Switch, SPST

Optical filter (red color)

Potentiometer 1k 2w

Knob, pointer 1 5/8"

Receptacle 120V a.c

Relay DPDT. 24V a.c.

Switch SPDT

Door, front terminal output

Data plate, hinged

Terminal, power output black

Terminal, power output red

Panel, front with PCB box

Support assembly, for rectifier

Chassis ASSEMBY

Contactor

Transducer, hall device 1000amp hta-1000-s/sp16

Bafle, and Transducer support

Stabilizer assembly

Wheel rear, assembly

Bracket, contactor

Support, power main transformer

Frame, lifting

Transformer, main assembly

Panel, primary connections and fuseholder

Fuse 5 amp

Rectifier, main (SCR) (figure 7-2)

Wheel front, rotating 6"

Capacitor, bank

List 7-1 Main assembly parts.