SECTION 3 - INSTALLATION

3.1 SELECTING A LOCATION AND MOVING WELDING POWER SOURCE.

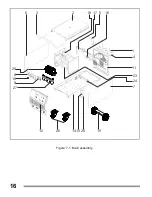

Figure 3-1. Connection for GMAW & FCAW process.

3

CAUTION

SEE SAFETY SIGNAL AT THE BEGINING THIS M ANUAL

Figure 3-2 Location and moving welding power source.

2

Rear

Left

Front

Right

Up

1

Figure 3-3 Work clamp.

3-2 INSTALLING WORK CLAMP.

Power Source

14 Pins

Wire

Feeder

GMAW Gun

Work Piece

Power Source

14 Pins

Wire

Feeder

GMAW Gun

Work Piece

-Solid Wire Weld Connection (GMAW);

Reverse Polarity (Electrode Positive.)

-Flux cored weld connection(FCAW); Straight

Polarity (Electrode Negative.)

1

. - 10 in (254 mm) open space

on right side and left of unit

for good airflow.

2

. - Lifting eye. Use only lifting

eye for lift unit.

9.5, 11.1 mm(3/8, 7/16")

1.- Work Cable from Unit.

2.- Contact Piece.

3.- Screw.

4.- Work Clamp.

5.- Washer.

Tools Needed

3

1

5

2

4