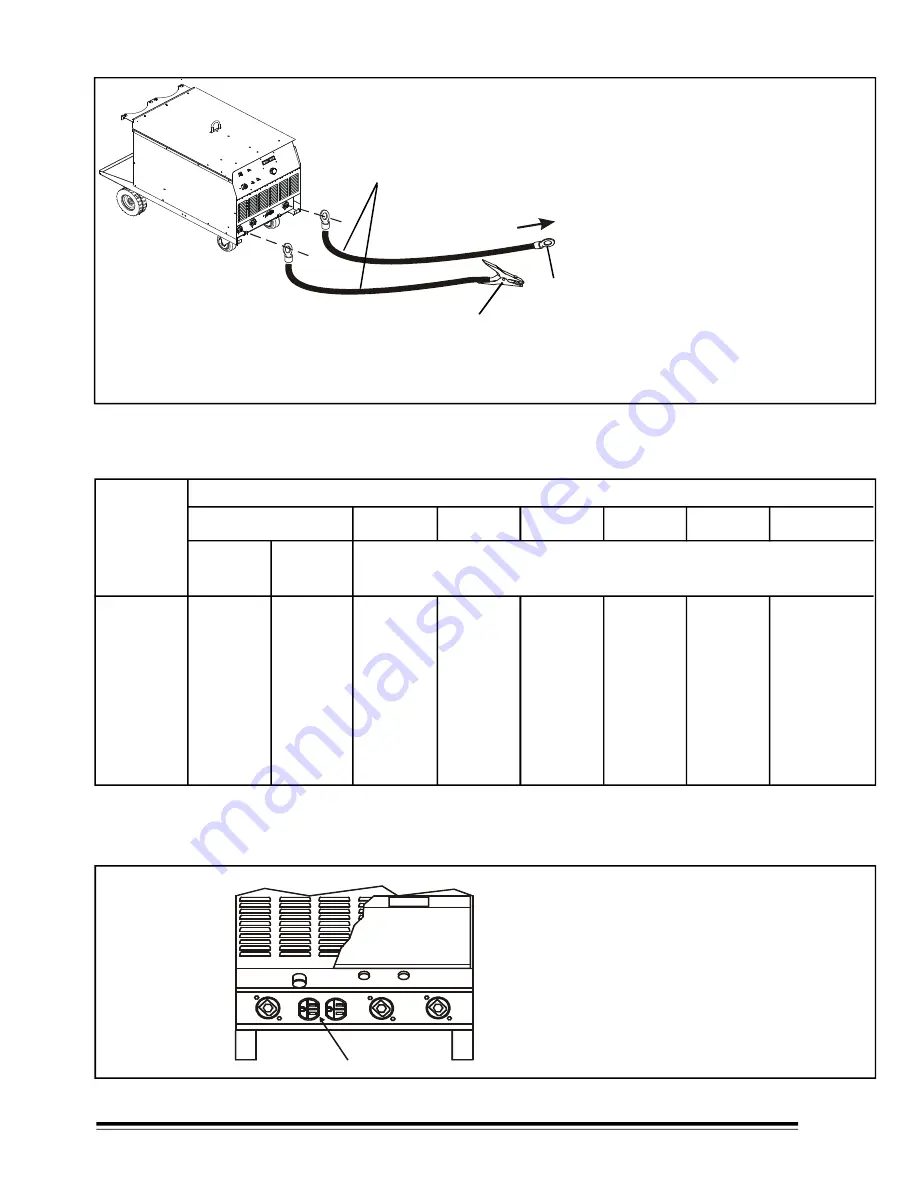

3-4 SELECTING AND PREPARING WELD OUTPUT CABLES.

1.- Weld circuit cable.

To select weld cable size, proceed as follows

:

a)- Calculate total cable length in weld circuit

b)- Determine maximum welding current and

duty cycle.

c)- Use table 3-1 to select proper cable size.

2.- Terminal lug. Use lugs of proper amperage

capacity and hole size for connecting to weld

output terminals.

3.- Work clamp. Instal on work cable.

Figure 3-4 Weld output cables

5

60 -100%

Duty cycle

100

150

200

250

300

350

400

500

600

700

800

4

3

3

2

1

1/0

1/0

2/0

3/0

4/0

4/0

4

3

2

1

1/0

2/0

2/0

3/0

4/0

2-2/0

2-2/0

4

2

1

1/0

2/0

3/0

3/0

4/0

2-2/0

2-3/0

2-3/0

3

1

1/0

2/0

3/0

4/0

4/0

2-2/0

2-3/0

2-4/0

2-4/0

2

1/0

2/0

3/0

4/0

2-2/0

2-2/0

2-3/0

2-4/0

3-3/0

3-4/0

1

2/0

3/0

4/0

2-2/0

2-3/0

2-3/0

2-4/0

3-3/0

3-4/0

3-4/0

1/0

3/0

4/0

2-2/0

2-3/0

2-3/0

2-4/0

3-3/0

3-4/0

3-4/0

4-4/0

1/0

3/0

4/0

2-2/0

2-3/0

2-4/0

2-4/0

3-3/0

3-4/0

4-4/0

4-4/0

10 - 60%

Duty cycle

10 - 100% Duty cycle.

Welding

a mp e r e s

150 ft

(45 m)

200 ft

(60 m)

250 ft

(75 m)

300 ft

(90 m)

350 ft

(105 m)

400 ft

(120 m)

100 ft (30 m) or less

* Weld cable size (AWG) is based on either a 4 volts or less drop or a current density of not more than 300 circular mils per ampere. Use

weld cable with insulation rating equal to or greater than the open-circuit voltage of the unit.

Table 3-1 Weld cable size.*

Total cable (Copper) length in weld circuit not exceeding

1

.-Duplex receptacle (RC2), this receptacle provide up

to (120V @10 A) a.c., the power is shared between

Remote-14 (RC8), CB1 protects to RC2 and RC8 from

overload.

Figure 3-5. 120 V a.c. duplex receptacle.

3-5 120 V a.c. DUPLEX RECEPTACLE.

1

2

3

10 ft (3m)

10 ft (3m)

For Example, Total cable length in weld circuit = 20 ft (6 m)

1

To wire feeder.