Page | 4

PRODUCT INFORMATION

ABOUT THE COM AX ONE™

The Compax One

™

is a smart waste bin, which automatically reduces waste by up to 15 times its original volume by use of a

unique vacuum technology. The Compax One

™

is mainly intended for compaction of paper towels but is nonetheless capable of

compacting most general waste. The Compax One

™

is equipped with sensors that monitor the waste fullness level and detects

motion. As paper waste is loaded into the Compax One Original Bag

™

, the appliance trigger and initiates a compression cycle

automatically as soon as the waste fullness level exceeds ¾ and the room is cleared.

1

The motion detector is mainly

implemented to ensure the safety of users and other personnel, in addition to availability of the product. Hence, the Compax

One

™

is always ready for accommodating waste.

2

Additional safety is implemented through sensors monitoring resistance and

abrupt movement during opening and closing of the lid. If there is too much resistance, i.e., something is hindering the lid

movement, the operation is aborted and reversed.

OVERALL FUNCTIONALITY

During a compression cycle, an electrically operated lid rotates down and seals off the Compax One Original Bag

™

before the

internal air is evacuated and the content thereby compacted as vacuum is attained. The overall functionality of the Compax

One

™

is here provided through the six stages of a compression cycle.

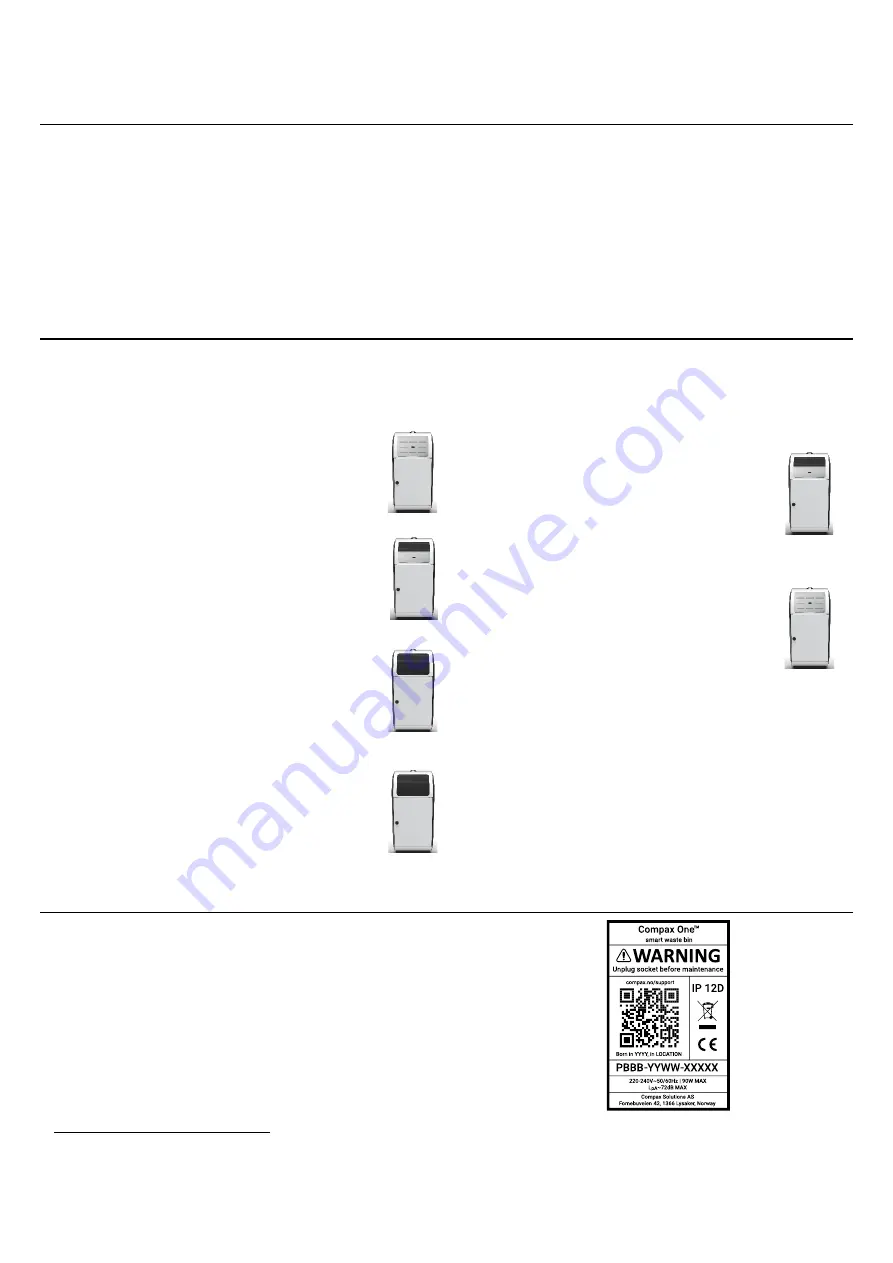

STAGE 1: OPEN CONFIGURATION

The Compax One

™

is in normal or stand-by mode

with the lid open, ready for accommodation of

waste. The appliance is used in the same way as a

regular waste bin.

STAGE 2: CLOSING CONFIGURATION

In order for the Compax One

™

to initiate a

compression cycle, the waste fullness level must be

triggered. The electrically operated lid then rotates

down to seal the Compax One Original Bag

™

.

STAGE 3: CLOSED CONFIGURATION

To ensure sealing of the waste bag, a gasket is

attached on top of the bag holder device.

When the

lid reaches the closed position, the Compax One

Original Bag

™

is sealed between the gasket and the

lid, and evacuation of the internal air is initiated.

STAGE 4: COMPRESSING CONFIGURATION

When the Compax One Original Bag

™

is sealed, the

air is evacuated from the bag. The shape and design

of the lid ensures a smooth distribution of the

airflow, thus preventing clogging of the system.

Access to the internal electronics is impeded by a

cover closing the accommodation hole during compression.

STAGE 5: OPENING CONFIGURATION

After approximately 70 seconds,

3

when the

waste is thoroughly compressed, vacuum is

released, and the Compax One Original Bag

™

is

no longer sealed. Ambient pressure is let back

into the waste bag, the compressed waste falls

to the bottom of the waste bag, and the lid

rotates back up to the upper position.

STAGE 6: OPEN CONFIGURATION

The Compax One

™

is now back in normal or

stand-by mode with the lid open. Hence, the

Compax One

™

is ready for additional

accommodation of waste.

NOTE:

For the Compax One

™

to function properly and as

intended, the disposable Compax One Original Bag

™

, must

be installed correctly. The waste bag must be at least half

full before proper compaction is noticeable. Otherwise, the

waste bag is susceptible to clog the evacuation slits in the

lid and prevent the remaining air from being evacuated.

Damage may occur if the door is opened during

compression cycle

PRODUCT MARKING

Ea h Com a One™ is mar ed with a label li e the one ro ided in the

example to the right. This label contains information about your

Com a One™ s h as serial n mber I rating noise le el and other

important information.

NOTE:

Do not re

mo e this label from yo r Com a One™

.

Removing the label may affect the warranty of your product.

1

Trigger limit may be altered based on customer preference.

2

An ongoing compression cycle may be allowed to complete based on customer preference.

3

Cycle time may be shortened or prolonged based on customer preference.