Compcooler, keep your body cool and comfortable in harsh conditions.

9

Remote controller connection

User may remove or replace the controller from chiller unit by disconnect or connect 5 pins

aero connector.

Cooling Garment Connection

User may connect the chiller with Compcooler Cooling Vest by quick release fitting.

Or user may remove the quick fitting from extension hose and replace the new fittings to

compatible with other cooling garment.

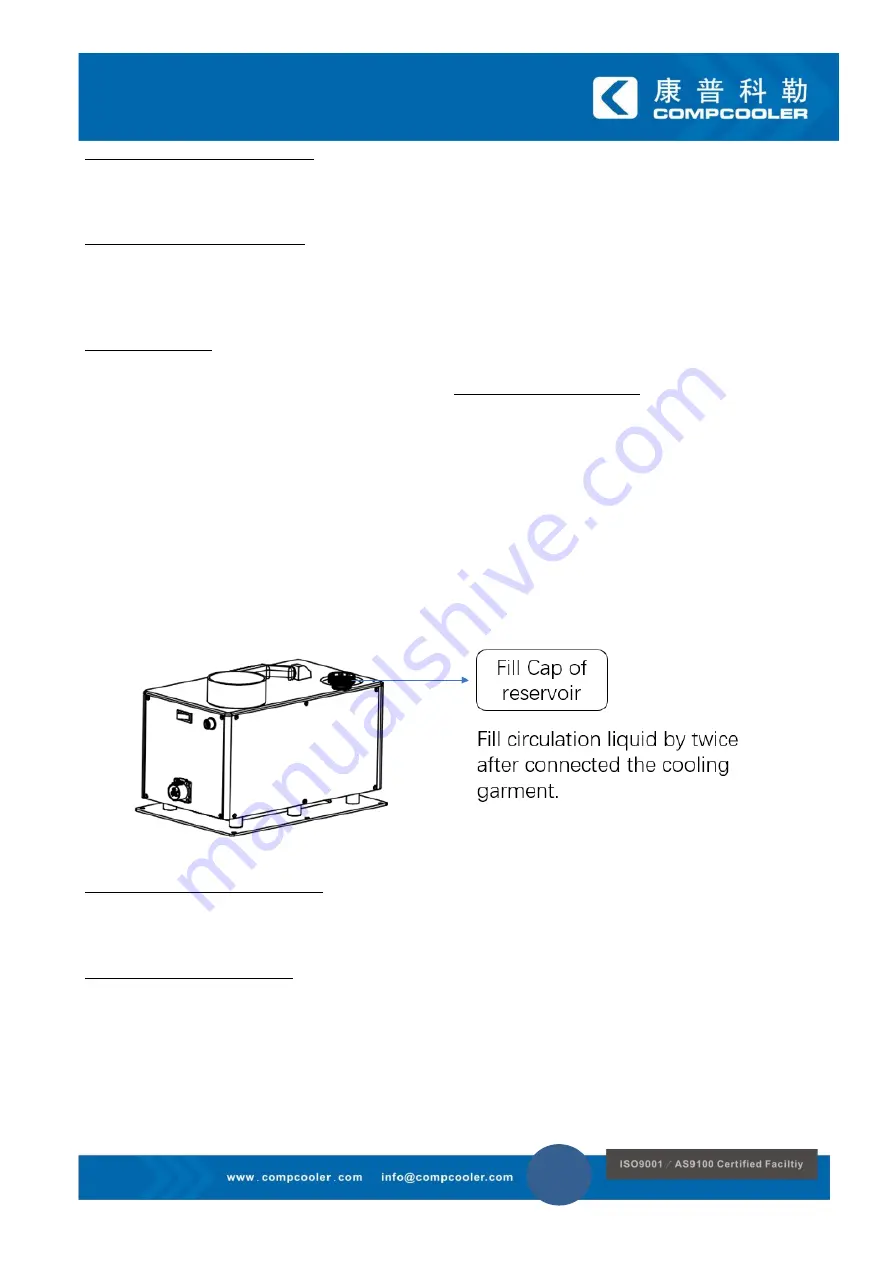

Circulation Liquid

User needs to fill circulation liquid by twice.

The first time, remove the filler cap from top side,

add liquid to full by funnel,

connect the cooling

garment, turn on the pump and circulates the liquid from reservoir to cooling garment.

The second time,

keep running and allow the liquid cooling garment fill with water for 30-60

seconds (without cooling), refill again to full (maybe couple times, be patient), then tight the filler

cap.

Clean or distilled water is fine if ambient more than 1

℃

Deionized water for isolation request.

Anti-freeze liquid for ambient below 0

℃

.

DO NOT use salt water, caustic, corrosive or flammable fluids!

Refrigeration or Pre-cool Testing

User may turn on the system and start refrigeration, no pump circulation, temperature will down

in minutes. Cooling unit will be in standby mode once liquid temperature reaches to setting point.

Fresh Air Tubing Assembly

User

may assemble 3”fresh air inlet tubing from top panel of chiller.